| Author | Message | ||

Gentleman_jon |

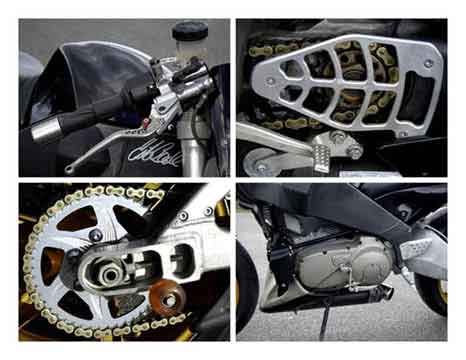

When I bought Lil' Blackie, I decided to make a work log for the bike, initially for warranty purposes. Subsequently, I discovered that the log was extremely useful as a reference to modifications, parts, and especially service intervals. Begging every one's indulgence, I now post the log here , on the outside chance that one brother or another may find something useful within. I have not corrected any spelling, not only out of sloth, but also to maintain the spontaneous, off the cuff spirit that maintaining such a log has entailed. Finally, I would like to thank all the brothers, you know who you are, who inspired, encouraged, worked on the bike, and even those, who, from time to time, have disparaged my modest efforts. Lil blackie Work Log 2006 1. 15 May 2006 Picked up bike in Syracuse, towed to Sag Harbor 2. 16 May checked a. Oil level b Tire pressure c. loosend chain d. discovered Race ecm. 3. 18. May a. Washed b. set up suspension: front 3/ 1/ 1.25 Rear 7 .5/,75 c. removed mirrors, plugged holes d. installed bar end mirror. e. Test ride. 4. 19 May Installed R tail with Brian 5. 20 May Picked up nail, ordered new pair Dunlop Qualifiers 6. 22. May Installed Shock Racing Mini 6 LED directionals, 10 ohm, 10 watt wirewound resistors in parallel. 7. 23 May: Polished headers/ install 50 thooth rear sprocket/ shorten chain 8. 24 May: Polished headers with 320/600 grit wet+dry sandpaper 9 25. May: install Dunlop Qualifier tires, new front + rear valve stem 500 miles. 10. 25 May Install frame pucks 11. 26 May Install Drummer muffler, three new steel bands on rear mount. 12. 26 May Key Switch fuse repeated shorts. 13. 27 May mounted electronics solidly in R tail/ checked for short in front / secured European running light plug, taped up exposed wiring. Shorts apparently fixed. 14. 28 May lube and adjust chain 15. 28 May lube clutch cabe and grease cable end at lever 16. 29 May received work order from original dealer, discover Lower ratio in primary, ordered 46 tooth rear sprocket. 17. 5 June installed Drummer front sprocket guard. 18. 6 June Install Buell Deluxe seat, broke bracket welded to subframe: doesn’t seem necessary. 19. 8 June install 46 tooth rear sprocket, shorten chain 20. 9 June Install Laverda Jota handlebars 21. 9 June install K+N air filter 22. 9 June Install Buell Traction hand grips 23. 13 June 1000 mile service: change oil, gear oil, oil filter, chech primary chain play to 3/4”.. (noteTPS reset when Race Ecm was installed by dealer). Engine Mobil One 15W50 / Primary chain case: Mobile One 75w90 gear oil. 24. 13 June Install Trojan Low Profile intake vents. Painted with black grill paint, attach grills with “Goop” 25. 20 June: Swap out modified suspension from old Yaller. 26. 29 June, replaced rusted bolts on swing arm, fixed front end short, 27. 29 June Installed Crystal Orange Ricta front fork and rear fors sliders 28. 29 June Rerouted handlebar wires 29. 03 July Install Tomasselli Adjustable Clubman’s bars replacing Laverda bars . 30. 05 July re install Tomasselli’s using additional handlebar clamp as riser 31. 09 July oil and adust chain, seems to be stretching. Researched chains. 1500 mi. ordered DID 520 ERV3 racing chain and chain riveter kit. 32. 10 July install Shindy 14mm front brake master cylinder, part #17652. Bought from Dennis Kirk, part no. 193154 $146.99 Bleed front brake, readjust bars. 33. 10 July, noted small cut in rear tire, ordered new set of Dunlop Qualifiiers 34. 11 July Painted timing cover, and primary side inspection ports to match cases using Buell paint Magnesium tone 35. 12 July installed new front fender to replace one damaged in parking lot incident. 36. 12 July replaced front brake caliper screws that had come loose with s/s , locktite blue. 37. 13 July repaired horn: had come off its bracket used locknuts. 38. 13 July adjusted idle screw down to 950-1000 rpm, to cure problem of idle “hanging” at 2000 rpm after engine was thoroughly warmed up. Greatly improved gas milage. 39. 14 July replaced both tires with new Dunlop Qualifiers at 1810 mi.. Rear tire had a cut and a staple in it. 40. Ordered black K+S bar ends from Dennis Kirk/ Tires from TIE. 41. 18 July. Reinstalled Tomasselli bars using two handlebar clamps as spacers: ground tops of the intermediate clamps with belt sander. 42. 18 July repainted inspection ports and timing cover with Buell magnesium tone spray paint to match engine cases. 43. 20 JulyInstalled K+S black aluminum knurled bar ends and custom mirror mount. 44. 31 July battery connections loosend. Removed, clean connections tightend down with wrench instead of screw driver, used locktite blue on screws. Eliminates hesitation on start. 45. Received Drummer Catch can, upgraded spark plug wires, Iridium spark plugs, chain and chain rivet tool 46. New flip top helmet: Nolan N102 glossy black, removed flip down sun shade. 47. Modified front sprocket guard: cut the front of an OEM part, and installed it under the Drummer Billet guard to protect the electrics. 48. 11 Aug Installed Drummer Catch Can 49. 11 Aug Installed new Spark plug wires 50 . 11 Aug installed new Denso Iridium spark plugs: front was fouled. 51. 14 Aug installed new chain. DID 520 ERV3 racing chain. Fits sprocket much better. Replaced DID ERT 2. Tensile strength: ERV = 8600, ERT = 8100 . Used Pro Motion chain tool. Worked great. Mileage = 2650. 52. 15 August Adjusted chain with rachet strap to hold suspension compressed: approx.1” at full compression. 52. 15 August Reduce front preload one turn, to increase steering quickness. Went from 3.0 lines showing to 4.0 lines showing. Note: seems to improve turn in slightly. Like it. 53. 15 August added 16 oz. oil to middle mark on dip stick. was below stick. Mileage:2650 54. Order Shock Racing Mini 1 metal directionals to replace plastic ones that keep breaking. 55. Added one click of rear shock preload to increase turn in speed. slight improvement. Current suspension settings: Front: 4 lines showing rear: six clicks 56. Drained catch can after about 100 miles: got a couple of ounces of clear water. 57. 18 August Installed Shock Mini 1’s in rear. Will order for front. 58. 18 Aug. installed stainless steel Allen head screws to hold on license plate. 59. 18 Aug revised suspension settings: increase rear compression 1/2 turn clockwise, increase front rebound 1/2 turn clockwise current settings Front: 4 lines showing 1 turn compression 1/2 turn rebound Rear 6 clicks preload 1/2 turn compress 1 turn rebound 60. 20 Aug. Test ride: improvement in turn in. Note: 3000 mile mark reached. 61. 24 August repair horn, mounting strip broke, fabricated new one out of brass strip 62. 24 Aug top gearshift lever screw fell out, replaced with s/s allen 10/24 machine screw and nylock nut. 63. 24 Aug replace handbar controls screws with s/s. 64. 30 Aug replaced Shock mini 6 directionals with Mini 1’s in front to match back. 65. 2 Sep tightened kick stand bolt used locktite blue, stand was loose and floppy. 66. 7 Sep added two clicks to the steering damper from soft. total = 10? road test: added stabillity in fast sweepers. Note after 100 fast miles: handling seems just right. 67. 9 SepRepaired signal sticking by loosening new s/s bolts on left handlebar control. 68. 9 SepNoticed rust on bottom of muffler: just dirt, not rust. 69. 9 Sep Received new license plate: XB12SR 70. 10 Sep added 4 oz oil to bring up to lower mark. Milage = 3415 71. 12 September 3550 miles. changed primary oil to HD Formula +: worried about damage to stator from Mobil One. 72. 12 September : replaced under front sprocket with new plasitic piece from 2004 . 73. 12 Sep. replace front axle, threads where a bit messed up on original. works fine. 74. 12 Sep. Oiled chain with PJ 1, wiped clean before and after. 3600 mi. No apparent stretch on chain after 1000 miles. 75. 12 Sep replaced gearshift rubber . 76. 13 Sep Added engine oil. About 8 ounces, brought the level up to 3/4 to the top mark to see if engine fan will run less.3600 mi. 77. 23 Sep . Went to Buell Day at Libery. Passed 4000 miles on way home. Noticed broken front isolator . Ordered from Stone Mountain. Part Nº for kit:L 10501.02A8 cost $89 shipped. added 4 oz upon return to bring to lower mark on dipstick. Need to oil chain soon. 78. Ordered spare lever for front brake from Dennis Kirk after discovering that it is not a common item.( Later figured out how to modifyBuell lever to suit with 10/32 Button head screw. 79. 27 Sep. Installed new isolator kit. took about half hour. Instead of a jack under the muffler, I used a strap around the frame and under the muffler to hold the engine in place while the isolator was replaced. 80. 28 Sep. Oiled chain, at 4085 miles. chain hasn’t stretched. 81. 28 Sep. reglued left grip, tightented mirror, to reduce vibration. 82. 30 Sep replaced screws that hold inspection plates on primary with S/S allen heads, lock washers. 83. 2 Oct. noticed that no water coming out of catch can now that weather is cooler, later discover petcock was left open. 84. 2 October. Installed replacement brake lever as a test. The replacement part looked different than the one that came with it. Part No 17-65L from Shindy, via Dennis Kirk. 85. 5000 Mile check coming soon: a. Change engine oil and filter b. Change primary oil c. Check primary and secondary chain tension d. change tires e. tighten Head bearings. f. clean rust off front sprocket. 86.10 October Ordered CRG brake and clutch levers 87. 10 October. Repolished headers, using 320, 600, 1000 & 1500 wet and dry, then Eagle One polish. Shine like chrome. 88. 15 Oct Modified stock Buell Brake lever with 10-32 button head screw to work in Shindy 14mm Nissan brake perch. Worked like a charm. Test to design mod. required by CRG levers to arrive soon. Will shortly have 4 usable brake levers. 89. 18 Oct. clean and oil chain, rear sprocket. 4485 miles. 90. 19 Oct Softened up front suspension to make turn in easier. Current settings: Front : 5 lines showing/ C= 1 1/2 turns out / R = 1 turn out Rear: 6 clicks / C= 1/2 turn out / R = 1 turn out Steering damper 10 clicks out from full soft. Seems to make bike steer quicker, still stable without damper, ride is good. Note: after spirited group ride, I decided to increase steering damper 1 click to 11 out to settle the bike down a bit. Handling is the best of both Buells I have had. 91. 21 Oct. added 12 0z. oil. Milage = 4535 Headers still very shiny, slight golden hue. 92. 25 Oct. install CRG Levers. Clutch #AN 621 Brake # AN-531 required small shim at the front.Lubricated Clutch cable. Might increase shim to bring brake lever back. 93. 25 Oct Checked front and rear sag: Front = 47mm Rear = 45mm This compares with standard 35mm and 32mm. 94. Orderd HVMP bar ends, to protect levers and reduce vibration. 95. 26 Oct. tried to go 6 lines out on front fork preload to see if that was better. Turned compression and rebound damping in to half turn. Bike was looser in front, went back to previous setting. Emailed Ed Kwaterski and called to discuss sag situation. Ed emailed back. Probably need new springs front and rear. I asked for quote. 96. 30 Oct Modified CRG brake lever, 1/4”-20 stainless set screw at top, recontoured bottom of jaws, to tighten grip on shindy front brake master cyclinder, and move lever toward handle bar. 97. 30 Oct. Rear tire is worn out. Milage 4850. Life = 3000 miles. Got 4500 out of Michelin Pilot powers. 98. 31 Oct. Reset shock and forks. I had turned the screws out to 1 to 1/12 turns to compensate for reducing front preload. Mistake. Screwed everything in to 1/2 turn out. Much better, less wallow ing turns. 99. 8 Nov. Re set handle bar clamps to move bars back about an inch and a half, by reversing the top pair of clamps. 100. 9 Nov Designed a handlebar riser. Sent to Hanyes and Andy Toro for estimate. 101. 15 Nov. 5000 mile Check up 5065 miles a. Change Engine oil Mobil One 15W50 extended life b. Change Oil Filter c. Change Primary oil Harley Formula+ d. Change and Balance tires: Dunlop Qualifiers. Used NoMar manual changer. e. Lube and Adjust chain: no visible wear or stretch f. check primary chain: OK : 3/4” cold. g. Clean bike h. to do: Check Steering bearings 102. 22 Nov . Installed X-1 Timing cover, polished, with engraved Pegasus. Got it on eBay. 103. 23 Nov. Painted X-1 Timing cover to match engine cases with Buell Magnesium Tone spray touch up paint. Primed with Krylon grey primer, Three coats paint. Baked at 200º for 1/2 hr. between coats. Looks nice on the bike, like it better than polished. Fastened with 10/30 stainless allen head screws. I would like to take this opportunity to wish every brother and his dear ones, the very best wishes for the holiday season, and a new year of swift and safe riding. | ||

Teeps |

Great report/log. I don't have the attention span... or eye for detail. | ||

Diablobrian |

The only thing I see that worried me was replacing front brake caliper hardware with Stainless steel. Stainless steel hardware does not have the tensile strength of the steel stuff which is at least a grade 5 or 8. The stainless bolts could shear at the worst possible moment. So be careful Jon! | ||

Daves |

Those CRGs sure look good!  | ||

Buellfighter |

Hey, that looks a lot like my log!!! 1. Check the oil 2. Check the chain 3. Fill the gas tank | ||

Rigman |

Yeah mine to. 1.Check if key fits ignition 2.Turn to "On" position 3.Start motorcycle and drive off on one wheel | ||

Djkaplan |

"CONFESSIONS OF A BUELL ADDICT" Gambling and drugs aren't as much fun... you probably won't get an intervention here. | ||

Ds_tiger |

umm- errr- ahhh HUH?  | ||

Wcbrracing |

but when did you get Erik to sign the frame??? | ||

Gentleman_jon |

Teeps - Thank you. Fighter - After looking at your magnificent tuber, I can't help thinking that your log might be just ever so slightly understated. For example, you apparently omitted some of the " Polished the Chrome and Aluminum today" entries.  Daves - Glad you like the levers you sold me:-) Brian - Thanks for the heads up! I am going to quit doing those stoppies right away! (Seriously, modern stainless steels are pretty strong. In addition, the different in strength would be relatively small compared to the factor of safety incorporated in to a properly designed fastener, which should equal at least two. Finally the resistance to crevice corrosion, especially at the the point of maximum shear, where the caliper meets the brake bracket on the fork, could outweigh the difference is shear strength over a period of time. ) Steven- I know EXACTLY what you mean. Reading this post is a bit like reading the phone book. The point of it might be to explore the extent to which some Buelligans spend their time and money on their motorbikes, and to show the effort that was required to get Lil' Blackie, and other modified Buells, to their current state. Will anyone be interested? Hard to say. Many won't be, that's for sure. Hopefully one or two brothers will benefit in some way, and that is about as much as one can expect from any post, isn't it? Eric - Erik Buell sincerely enjoys meeting the faithful and appears at many demo days and other Buell events during the course of the year. There always seems to be some paint pens around and he is more than happy to sign the bike of anyone who asks. Mine was signed at a recent demo day at Liberty HD in Rahway NJ, one of our enthusiastic sponsors. I believe that this connection with the Buell community is not only unique, but contributes a lot to the bikes and the experience of owning one. | ||

Diablobrian |

If you're comfortable with it Jon that's cool, I just wanted to be sure you knew that there was a difference in strength between the fasteners. Working as a machinist I saw a fair number of failed stainless bolts in high load applications. I laid out the mechanical aspects of what has been done to my bike in th KV "show us your power" thread. The cosmetic changes are pretty clear and detailed in my bio. I really enjoy the community feeling we have here among Buellers. That was the best part of going to Homecoming this year. It was fun putting faces to the screen names I've been talking to for so long. It was like a family reunion in some respects with all of the friends you've never met kind of vibe. You could sit down at any table and strike up a conversation. It is especially cool when the guy who's name is on the company comes up and sits down at the table and joins the conversation, and fields all of our questions (that he's heard a thousand times before) with a smile on his face. Incredible. | ||

Sweatmark |

Jon - thanks for sharing the work log and inspiration... need to do this myself! Does anyone know of a list that documents the XB hardware/fasteners size and drivers? I'm jotting down the tools required for different tasks in the factory manual (in Notes portion of torque table). |