| Author |

Message |

Brineusaf

| | Posted on Tuesday, November 28, 2006 - 05:47 am: |

|

Don't want to click to edit:

If you were to use shim's you would be compromising space between the oil pump gear and the cams - which could effect lubrication, and flow of the oil. |

Reepicheep

| | Posted on Tuesday, November 28, 2006 - 10:53 am: |

|

It's in the knowledge vault, I will have to go hunting.

I don't think shims will help, I think it needs to go the other way, to make the oil pump case "shorter" so that oil pump gear rides in the higher on the pinion gear. Though riding "squarely" may well have been a factor as well. |

Reepicheep

| | Posted on Tuesday, November 28, 2006 - 11:02 am: |

|

Here it is...

Nice work by WhiteBuell!

http://www.badweatherbikers.com/cgibin/discus/show .cgi?tpc=3842&post=282150#POST282150 |

Whodom

| | Posted on Tuesday, November 28, 2006 - 11:12 am: |

|

I don't think shims will help, I think it needs to go the other way, to make the oil pump case "shorter" so that oil pump gear rides in the higher on the pinion gear. Though riding "squarely" may well have been a factor as well.

Reepi,

He may be talking about putting a spacer (washer) under the driven gear on the oil pump, i.e.- between the gear and the body of the oil pump. This would have the same effect as machining material off the top of the oil pump body, raising the driven gear on the oil pump relative to the drive gear on the crankshaft.

I don't have a parts book handy so I'm not exactly sure how the internals are put together (how does the shaft attach to the gerotor?), but this would be worth a look. If you could simply disassemble your oil pump, slip a washer or two over the gear shaft, and reassemble it, that would be an awfully easy fix.

(Message edited by whodom on November 28, 2006) |

Brineusaf

| | Posted on Tuesday, November 28, 2006 - 11:12 am: |

|

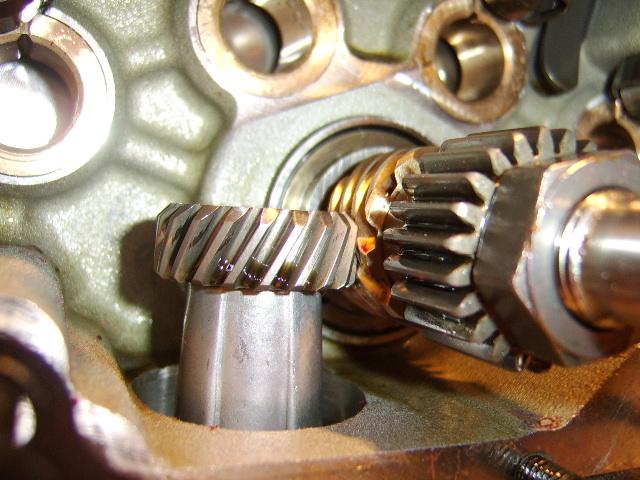

Here is a picture of mine, as you can see it already sits damn near perfect.

I took a wear pattern, but forgot to photograph, and it was dead on in the center, not too high, not too low.

Keep in mind this IS A 2006

A shim isn't needed on mine.

Edit- I don't have a parts book to see how it pieces together to see if one would be possible either.

(Message edited by brineusaf on November 28, 2006) |

Reepicheep

| | Posted on Tuesday, November 28, 2006 - 11:13 am: |

|

Ah! And I see what you mean about the shims. Need an exploded view of the oil pump to see if you could shim up that oil pump gear (not the pinion gear) to get it higher on the pinion gear (rather then machine down the case of the oil pump body to do the same thing). |

Reepicheep

| | Posted on Tuesday, November 28, 2006 - 11:17 am: |

|

Great shot! Very cool!

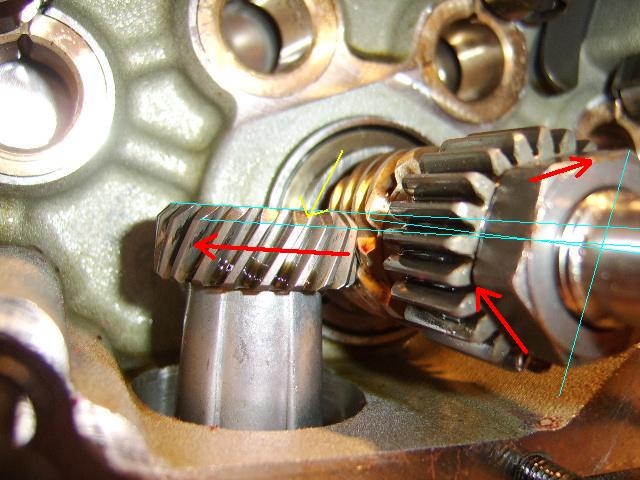

I think the issue WhiteBuell is describing is the fact that your gear on the oil pump sits too low relative to that pinion gear.

Looking at yours, it looks the same (as I suspect all are)... I think the oil pump gear should should be higher (and centered on the pinion gear). The picture makes it look like it sits a shade low.

This is all speculation though, WhiteBuell did two things, hardened the gear and changed the alignment. One or both could have been factors in what appears to be a solution for him. |

Whodom

| | Posted on Tuesday, November 28, 2006 - 11:20 am: |

|

Here is a picture of mine, as you can see it already sits damn near perfect.

Brine, that driven gear looks measurably below the crankshaft centerline to me. Whitebuell's theory was that the center of the driven gear should be exactly on the vertical centerline of the crankshaft for the optimum tooth mesh.

The amount of wear on your shiny bronze gear is kind of hard to tell from the photos; is it OK? If so, the bronze gear may be fine without doing anything else. THAT would be nice. |

Brineusaf

| | Posted on Tuesday, November 28, 2006 - 12:30 pm: |

|

Brine, that driven gear looks measurably below the crankshaft centerline to me. Whitebuell's theory was that the center of the driven gear should be exactly on the vertical centerline of the crankshaft for the optimum tooth mesh.

The amount of wear on your shiny bronze gear is kind of hard to tell from the photos; is it OK? If so, the bronze gear may be fine without doing anything else. THAT would be nice.

It is on the center, if you look at the bottom of the picture, you can see the casing... showing the camera was tilted when the photo was taken.

I don't have an instrument to measure with, but wear is minimal, and wear pattern is awesome.

KEEP IN MIND THIS IS A 2006 WITH UNDER 5K

(I am doing some work and figured I'd contribute some pics for people to relate to)

Edit- I'm not concerned with someone's "Theory" if the placement was a real problem, Buell would have issued a recall, or fixed it on newer models- which they might have. Obviously BMC realized that the gear has some problems, which is why they offer a "Pro-Series", and decided it wasn't the placement. IMO, Buell has a little more expertise...

(Message edited by brineusaf on November 28, 2006) |

Whodom

| | Posted on Tuesday, November 28, 2006 - 01:32 pm: |

|

Brine,

Glad to hear your wear is minimal. It looks like you won't have a problem, but it wouldn't hurt to check again in 20 or 30k miles.

I'm not concerned with someone's "Theory" if the placement was a real problem, Buell would have issued a recall, or fixed it on newer models- which they might have. Obviously BMC realized that the gear has some problems, which is why they offer a "Pro-Series", and decided it wasn't the placement. IMO, Buell has a little more expertise...

Buell evidently has fixed the problem with the new gear (which your bike is already equipped with) and/or correcting the gear alignment. AFAIK, Buell has never acknowledged that there is/was a problem, but they did come out with a new gear (factory installed on 06 and up Buells) which would sure seem to indicate that they knew it. Even on the tube framed bikes, gear wear wasn't a universal problem: some bikes ate gears and some didn't. I've only seen a couple of posts regarding XB's with excessive gear wear.

As to Whitebuell's "theory"; his bike ate 2 or 3 gears before he got tired of replacing them, took matters into his own hands, and permanently corrected it. I think he's got pretty good evidence to show he knows what he's talking about. This was a good year or two before Buell came out with the Pro-series gear.

At any rate, your photos are a good indication that the gear wear problem has been eliminated on 06 and up bikes which is nice to know. |

Whitebuell

| | Posted on Tuesday, November 28, 2006 - 03:15 pm: |

|

Been reading it all here,looks like the problem still exists on some XB's ?

Brineusaf's bike has a wear pattern but no abnormal wear as he says.

My fix to the problem works perfect on my Buell and it works on the newer Buell's because it seems they(Buell company)also lined the pump gear up with the pinion gear on the XB models .

If i was Buell motorcompany i would make the pump wheel slightly bigger(now it is 11.2mm high,i would make it 13 mm high) so that the bevelled edges aren't touching the side of the pinion gear teeth any longer.

Because they still touch the proseries wheel,you have that 'wear'pattern you are talking about in your post above.

I would also make the pinion gear as hard as the pump gear(like i did on my engine with the known results)to keep the wear down to a minimum.

I now have a pro-flow pump on the bike to solve the problem of oil scavenging,that pump has a wheel that sits on the shaft with a circlips . i have taken i apart and put the gear on the lathe to make the clips hole somewhat deeper,i then could shim the gear up so that it lines up perfectly with the pinion gear again.

I have now used the proseries gear to try and to see what it looks like if i have 12K or so on the bike,i will let you all now how things work out in time.

I do think,if i see the pictures from the german XB ,that i have made the wrong choice this time and better stayed with my first idea of case hardening the pinion gear instead of taking the proseries one.The pump gear is also case hardened in case you where wondering how hard that gear is.

I always heard in school that gears always should have the same hardness , why is Buell trying to change some natural laws that always have been working for lots of things?

Have someone make me a higher pump wheel is something i will try also,first ride the damn thing some more miles,it's time to enjoy some Red Shifts now

|

Diablobrian

| | Posted on Tuesday, November 28, 2006 - 04:29 pm: |

|

An engine is a complex piece of machinery.

Without manual inspection and tweaking at each stage of assembly there will always be

issues with "tolerance stacking" where the thousandths of an inch that is allowable

tolerance for each piece adds up to alignment problems on some finished components.

This problem is common to all complex machines built on an assembly line.

The misalignment is not large, but can be enough to cause small friction losses and

accelerates wear. However it is not enough to cause a catastrophic or untimely failure

in most cases.

This is one of the advantages to having a professional shop re-build your motor.

In the old days the art of "blue printing" was a well known way to get more out of an

engine. You would go through it by hand and return each part to an "ideal" spec.

It doesn't sound glamorous, but there were, and are, gains to be found in this.

All factories expect a certain number of products to be "lemons" because of small

differences from one machine to the next. This is part of the down side of high speed

production line manufacturing.

(Message edited by diablobrian on November 28, 2006) |

Reepicheep

| | Posted on Tuesday, November 28, 2006 - 05:19 pm: |

|

A piece of machinery that was cranking out engine cases and was built in 1947 and has been hacked and kludged so many times that no original part remains might be a factor as well. Or so I suspect with the tubers...

Thats also why I expect it "got better" with the XB's... new tooling and processes. |

M1combat

| | Posted on Tuesday, November 28, 2006 - 09:36 pm: |

|

"If i was Buell motorcompany i would make the pump wheel slightly bigger(now it is 11.2mm high,i would make it 13 mm high) so that the bevelled edges aren't touching the side of the pinion gear teeth any longer. "

Exactly... It looks to me that the beveled edge on the pump gear is doing the eating. That gear should be taller or higher to get the sharp AND harder beveled edge off of the teeth of the drive gear.

Any reason why Buell would have chosen to make the gear that's difficult to replace the softer one???

In any case... I don't think it would be a good idea to shim the gear (to make it higher) without also replacing the other gear at the same time. |

M1combat

| | Posted on Tuesday, November 28, 2006 - 09:49 pm: |

|

At least it's not grinding in with the sharp edge I guess, but it seems that the edge where the yellow arrow is pointing would be where the pressure is the greatest and the lower the driven gear gets the worse the problem becomes.

Just kindly call me "Master of the Obvious"  . . |

M1combat

| | Posted on Tuesday, November 28, 2006 - 10:51 pm: |

|

Would an imperfect gasket be a cause? Maybe when the pump is installed the gasket doesn't compress exactly the same amount on each side, resulting in a driven gear that's not in the right place AND not quite square? |

Whitebuell

| | Posted on Tuesday, November 28, 2006 - 11:59 pm: |

|

M1combat, that is exactly what i mean i my posts,so a bigger wheel and a hard steel drive wheel would correct the whole problem .

I think there is also the issue of cost here,they have to make a complete new oilpumpshaft with larger gear on top.

An imperfect gasket can also cause some minor misallignment,never looked that far to be honest .

My pump was mounted without gasket and the pro-flow that i have now uses an O-ring to seal the pump to the cases. |

M1combat

| | Posted on Wednesday, November 29, 2006 - 12:13 am: |

|

I was just agreeing with you  . .

I think when I replace my drive gear I'll re-mount w/o a gasket. I seriously doubt it's the magic bullet, but it at least helps with the gear positioning and as long as I can seal it, it should be good to go from that standpoint. |

Brineusaf

| | Posted on Wednesday, November 29, 2006 - 02:06 am: |

|

I knew nothing of gears supposed to have same hardness.

If they were both the same hardness though, wear would be less, but wouldn't the chancing of actual chipping or breakage be greater? (i do not know, i am asking)

Additionally, wear would be influenced by lubrication. If oil becomes low, wear would increase. Obviously... just something to keep in mind. Not all "flaws" are company error, in fact I think most are operator error. |

Alex

| | Posted on Wednesday, November 29, 2006 - 02:09 am: |

|

Forget about measuring the relative height between the pump gear and the drive gear with the engine not running. The oil pump drive shaft has a lot of axial play. The inclined teeth of the gear will force the gear (including its drive shaft) up when the engine is running until it bottoms out (caused by the washer and retaining ring inside the oil pump). So if You really like to know the relative position between the pump gear and the drive gear at least You need to pull up the pump gear.

I for myself do not believe in a misalignment causing excessive gear wear. There are so many other factors that could play a role. |

Brineusaf

| | Posted on Wednesday, November 29, 2006 - 02:33 am: |

|

Alex - sent you an email yesterday! get it?

Indeed I did notice that yesterday, that the gear does lift up some.

I personally don't think anything is wrong, mine is fine. I'm not burning through gears.

Here is the movement Alex mentioned.

It moves more than I could photograph, as I needed one hand to push the button on the camera - which was on a tripod to keep the same angle.

Also, this is however the gears are aligned RIGHT NOW, which means, if I were to rotate the crank, it could move up more.

I wasn't pulling it up hard, as you can see I wasn't even pulling, I was "pushing".

Movement in this position, with minimal force is 1/16 of an inch. Imagine if I were to pull it, and rotate the shaft - I'm positive it would have more movement.

Good job pointing that out Alex. |

Alex

| | Posted on Wednesday, November 29, 2006 - 07:27 am: |

|

Got Your mail, Kyle.

Will answer it within the next two hours. |

|