| Author | Message | ||

Daveinm |

I just got done drilling out and rethreading the hole in the primary that holds in the bolt for the shifter. The bolt snapped on me while tightening it to the torque values from the manual (22-24 ft. lbs. if I remember correctly). Pain in the A$$ to fix it. First drilled the bolt and tried Easy-Outs/Reverse Bits....didn't work. Then we just drilled the bolt out and threaded the hole and put in some Helicoils. This isn't the first bolt to snap like that. It has happened many times on a lot of different bolts on my bike and other Buells. It makes me question a few things...1) Are the torque values in the service manual correct? 2) Are the bolts low quality? 3) Is there maybe something that is degrading the strength of the bolts? My torque wrench is almost brand new, so I think it's gotta be decently accurate. Anyone have any experience or opinions on this? | ||

Ingemar |

No experience on the buell with it (although I've helicoiled many holes after snapped bolts in the past). Maybe you should have your torque wrench checked out. These things are sensitive and get out of wack over time. Just a thought. | ||

Emscityx |

I learned a while ago to verify inch-lbs vs. foot-lbs. Doubt it was that simple here, but you never know. | ||

Enduro261 |

Yes, I have had experience with the manual. I have busted the head off three screws by listening to the manual. Do not follow that thing at all. If it says 26 ftlbs I would suggest 20lbs. The only one I feel comfortable with is the axle and the front isolator bolt. I suggest that you tighten everything firmly with a little less torque than the manual suggest. | ||

Enduro261 |

And to add to your question. I think the bolt quality is pure crap. I had a mechanic look at the bolt and he said it reminded him of Japanese quality metals. | ||

Daveinm |

Ingemar: My torque wrench is not even a year old and has not seen much use. Even if it isn't perfectly calibrated, I don't think it would be off so much that these bolts should be breaking. Emscityx: Yeah, there's a pretty big difference there  You tighten a bolt 80 ft. lbs. instead of 80 in. lbs and you're definitely going to strip or break something. You tighten a bolt 80 ft. lbs. instead of 80 in. lbs and you're definitely going to strip or break something. Enduro261: Sounds like you're in the exact same mindset I'm in. It makes me uneasy working on the bikes not knowing if the torque values are correct. I'm always worried I'm going the break or strip something. I also agree that the bolts are crap. The hex bolts are the worst. Those hex heads strip out before you can even think about getting to the torque you're looking for. It's ridiculous! Are there any solutions to this problem? Is there anyone that can get a list of correct torque values? What about replacing the bolts with higher quality ones...maybe titanium? | ||

Ejiii |

I've also had problems with over torque using the minimum values stated in the service data. My new Drummer has a dent from the back claps being tightened to 5Nm. That is the minimum value. I don't like it at all. The Drummer is fine but the dent really bugs me. 2 - 3Nm seems more appropriate. I used a Snap-On Torquometer which is a totally sweet torque wrench. It's a bummer! | ||

Blake |

Using torque to achieve bolt preload is a guessing game. Between dry and lubricated, clean and dirty, and high quality versus low quality threads the preload developed under a set torque can vary by more than 50%. You'll note that the final preload of some of the most critical bolts on your engine, the cylinder/cylinder head bolts/studs do not rely upon a final torque value but depend upon a much more reliable turn of the nut method to achieve desired bolt preloading. What size bolt was that Dave? That 22-24 FT-LBs value is pretty significant. I know that the torque value for one of the rockerbox bolts in my '97 Cyclone's manual is too high. When tightening a bolt, liquid Loctite acts like a lubricant, so compared to a dry bolt installed without Loctite to the same torque, you'll develop upwards of 30% more tension in the bolt. There are theses and disertations and paper after paper written on the subject of bolt torque versus preload. Additionally, some high strength bolts should not be re-used in certain applications. By design, they deform plastically (stretch) upon initial installation and are thus unacceptable for re-use. On torque wrenches... even if accurate some are susceptible to significant error depending on how they are held/gripped during the torquing process. Lots of variables, including fastener quality. | ||

Stou |

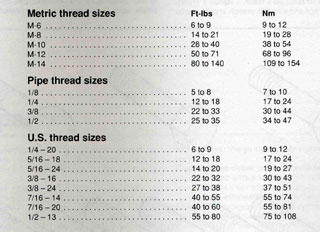

I don't know if it can help but here's a general chart of torque value by bolts size. Is it looking like the value you have in your service manual?  | ||

Blake |

For what grade of bolt? Each grade has a different chart like that. Very dangerous! Need more information.  | ||

Daveinm |

Blake: The bolt I snapped was the one that holds the shifter in. It's a big bolt compared to others on the bike. 5/16" I think. After putting the Helicoils in, I torqued it to 10, then 15, then 20 ft. lbs. Everything is cool now. | ||

Stou |

"For what grade of bolt? Each grade has a different chart like that. Very dangerous! Need more information." This is a general torque value chart for dry (unlubricated) for steel or cast iron. It can vary depending on the grade but it's a good reference chart. |