| Author |

Message |

Cataract2

| | Posted on Thursday, January 30, 2014 - 10:09 am: |

|

Old, there is a small 1/4" fine thread hole in the base of the pump. When you remove the snap ring (I listed the size snap ring pliers you need in this thread) you can just thread in a bolt of the size I listed and with a pair of pliers grab hold and pull. The pump will come out. Don't even need the tool listed for it.

Zeus, if you have any questions just ask them here. |

1313

| | Posted on Saturday, March 08, 2014 - 12:32 pm: |

|

That small hole in the pump is NOT fine thread.

1/4 - 20 all the way...

DAMHIK,

1313 |

Zac4mac

| | Posted on Sunday, March 09, 2014 - 01:28 pm: |

|

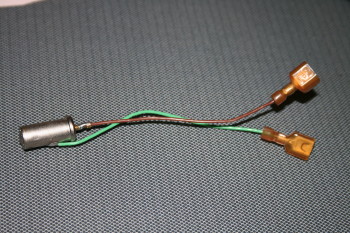

Another "BTW", I revisited my spare ass'y and the thermistor body is tinned, not aluminum.

Should be extremely easy to solder.

Z |

Oldog

| | Posted on Monday, March 10, 2014 - 03:00 pm: |

|

On reassembling the pump try some STP on the orings to help ease assembly issues,

I checked 1313's nib pump the resistor was almost out of spec I would suggest check when wired spec to be sure, also if you purchase the sensor the pump wiring harness has s small female disconnect and the sensor needs a male. |

Youk

| | Posted on Sunday, August 24, 2014 - 11:09 am: |

|

Guys, I just wanted anyone else attempting this repair to know it is not a difficult job. I waited till I needed a rear tire to do the repair, since the rear wheel is off, it is very easy to remove the swingarm, and get to the pump. I just followed the repair manual. I was able to easily solder the ground wire to the new sensor, I also soldered the wire from the original to the hot side of the sensor because the mating plug on the replacement sensor is a female spade, and the 1125 used a male spade. I used standard electrical solder, and a 33W pencil style iron. I would not do this with a hotter iron, I was concerned about causing damage to the sensor, or igniting fuel residue.

(Message edited by Youk on August 24, 2014) |

|