| Author | Message | ||

Timebandit |

I guess you're doing this without the service manual, eh? pulls right off. | ||

Timebandit |

you did remember to pull the thrust washer off of the balancer shaft before trying to remove the rotor, right? if you left that on, then the starter ring gear will hit it when you try to pull the rotor off. that could be the cause of your click. | ||

Bartone |

I do have the service manual. It uses the rotor removal tool..... For the thrust washer... If its what I'm thinking it is, it came off easily along with the cover. It's the one directly above the crank shaft? | ||

Timebandit |

yes, the thrust washer is on the balancer shaft, which is above the crank. I don't know which manual you have. it's clearly ID'd in the 2010 version on 3-77. and in the 2009 version on 3-75. consider that the HD manuals list all sorts of expensive proprietary tools, claiming that you need them only because HDMC wants to sell them to you. i've never needed any of the them other than the crank locker. i've never had to fight with a rotor to pull one off. should just come off easily. before I did my first rotor I did a dry run on the phone with two different guys at EBR and both of them told me that most of the special tools in the manual are unnecessary. that was my experience as well. if your rotor is reluctant to come off, then check to make sure your starter ring gear isn't engaged by the starter drive and that the sprag cluch is free/unbound. one thing to consider is that if you used a hot air gun to heat the loctite, or if you heated the crankshaft with a torch, then you've got a driveshaft that's been expanded by heat to grab the rotor and you'll have no hope of getting the rotor off. wait for it to cool. if you read the notes in the thread on how i did it, i used a torch to apply heat only to the corners of the nut, expanding the nut with heat while keeping the crankshaft cool. rotor practically fell off. (Message edited by timebandit on May 14, 2012) | ||

Bartone |

So this is what i have now. It still does not come off. The starter gear doesnt spin freely and im not sure how to unengange it.  | ||

Timebandit |

the picture brings a few questions to mind: 1. is that a picture of your bike or a stock photo of someone else's? 2. is that your 2009 rotor that's on the bike, or is that a photo of a 2010? I thought that only the 2010-spec rotors had the serial numbers engraved on the bowl. 3. Is your motor locked into the TDC position using the crank locker? i don't think it can be -- your engine looks like it's about 90-degrees off from proper position. if that picture is of your motor, then i can explain the problem. your starter ring gear is hitting the balancer. don't use a puller or you're guaranteed to do some serious damage. you never mentioned which manual you were using, 09 or 10. needless to say, if that's a photo of your bike then you're not following the instructions in the 2010 service manual. | ||

Bartone |

This is a picture of my bike with the unmodified rotor and it is locked in tdc with the crank locking tool I'm using a 2009 manual as my bike is a 2009 model assembled in 2008 The starter gear will move back and fourth freely about half an inch but no more same with the gear on the balancer shaft. But I can't spin either of them without turning the crankshaft So now I'm stuck and the rotor won't come out | ||

Bartone |

It could be that it is a 2010 spec rotor as there was warranty work done on the stator components but they did not specify what was changed when I bought the bike from the dealer used. | ||

Timebandit |

Not as if the numbers on the rotor are all that important, the serial numbers just caught my eye. The good news is that your starter movement sounds normal. The service procedures were revised in mid-2009 so that the procedures in the 2009 manual were superceded. This is why H-D and EBR tell everyone that they MUST follow the procedures in the 2010 manual, regardless of the year of their bike. When it comes to doing this job, the 2009 manual is good for toilet paper -- it leaves out an awful lot of useful information, and I think that's why you're stuck. You really should get your hands on a copy of the 2010 manual if you're going to be doing engine work. It's much better. My thoughts are that based on the photo, it looks like your engine is rotated into the wrong position. I'm thinking that you don't have the crank locking tool seated in the right hole. If you put a wrench on the crankshaft, can you rotate it in either direction or is it fully immobilized? (Make sure your battery is disconnected!) | ||

Bartone |

It is fully imobilized both directions so it should be in the right hole? Or is there more than one? I've seen a few other pictures where the the circular grooves on the rotor would be near the balancer shaft as well at the timing mark of the gear Ive noticed that my manual has just the bare info and skips a lot of steps. Where can I get the 2010 manual? Will you be able to help me out on this part as I want to finish this as soon as I can. | ||

Timebandit |

There are some tricks to working on this engine that aren't really covered in the manual. I can tell by looking at the photo that even though your motor may be locked, it is rotated into the wrong position. If you're locked in that position (immobilized in both directions?) then you're either in the wrong hole (wrong cylinder TDC) or your balancer is mis-timed. Which is the case will become evident once you get the rotor off and look at the timing marks that are behind it. Try this: see those 3 giant holes on the top of the balancer? Remove the locking tool, and rotate your engine so that the balancer rotates clockwise until the first big hole is located at about 3:15. You should find a locking hole in the lobe of the crankshaft at that position. Lock it in there. Your rotor / starter ring gear should now clear the balancer with no problems. I'll stay by the computer and watch for your answer. edit: fixed a typo (Message edited by timebandit on May 15, 2012) | ||

Timebandit |

To answer your question about where to get a 2010 manual: I got mine from Harley Davidson. | ||

Bartone |

Ok it's now locked in that position and it looks like everything is clear. But the rotor is still stuck there | ||

Timebandit |

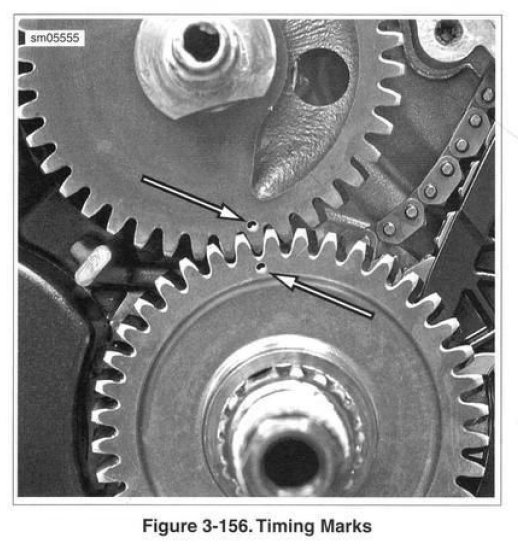

If you rotated it 72* and it locked, then you found the TDC hole for the other cylinder. that should put the little timing mark that used to be at 3:00 and move it so that it lines up with the other timing mark -- you'll need to confirm that the timing is aligned when the rotor comes off. Rotating into that position should also rotate the relief cut in the balancer so that it lines up parallel with the arc that's formed by the teeth of the starter ring gear. Now there should be full clearance between the starter ring gear and the balancer so that the rotor pulls right off. I see that you already removed the 6 mounting bolts for the sprag clutch. I didn't have to do that, I just removed the rotor/sprag/starter ring gear as one unit. With the bolts removed the rotor should come off of the sprag clutch once you overcome the 648. If you can't get the rotor off then something is stuck. Maybe you're one of those rare guys who needs a puller -- I've never seen it happen. FWIW, take another picture, showing the position of the balancer at the rotor, just to verify that the orientation is like I think it should be. If the orientation is right, I think you should be able to pull the rotor by hand. Somewhere around here on the forum is a method where somebody used longer bolts in the sprag holes to coax out a sticky rotor. I'll look for it while you snap a photo. edit:fixed a typo (Message edited by timebandit on May 15, 2012) | ||

Bartone |

ok here is the updated picture of it locked in the position you mentioned.  | ||

Timebandit |

sorry, when i try to enlarge the pic all i get are pixels. i'll pm you with my email so you can send me a full-res pic. | ||

Timebandit |

OK, got the pics. it looks you have rotated the motor into the proper position so that the balancer won't be interfering with the rotor or the starter ring gear. Now that you've cleared the balancer, the rotor should just pull right off. That's how it's worked on every bike I've done this with. you mention that the bike had warranty work done and the rotor might have been replaced? that makes me wonder if there could be some stray loctite that's holding things together. you might need a tool to get the rotor off...  just kidding. I'm thinking that at this point you might be one of those guys who needs to help coax the rotor off gently with a puller. I'm guessing that somebody might have liberally applied some loctite when they put the replacement rotor on, and that's binding things together. if you don't have the rotor puller, here's a thread where Naillace shows how to use long bolts with backing nuts to push the rotor off of the crankshaft: http://badweatherbikers.com/buell/messages/290431/664864.html when you get it off, don't forget to confirm that the two timing holes are lined up with each other, in-line with an imaginary line that goes from the crankshaft tot he upper balancer shaft. | ||

Timebandit |

like this:  | ||

Bartone |

I'm not quite sure what he did with the extended bolts. Did he just screw them into the rotor so that the ends hits the starter gear and in turn pushes the stator outwards? | ||

Timebandit |

they were not the same thread size as the rotor bolts, so they weren't actually threaded into the rotor, they passed through. he used the nuts on the backside to lift the rotor off of the starter gear. | ||

Bartone |

I wonder how he did that. There is barely any room to fit any tool behind the rotor. There is less than half an inch. | ||

Sparky |

Nillaice said, "i used some 1/4-20 allen bolts and nuts to do it, but longer metric M-8 (IIRC) bolts would do the trick easier, cuz they thread right into the rotor => no backing nut necesary" If I'm reading that right, try getting longer M-8 bolts instead of using 1/4-20 bolts. Then you don't need backing nuts. | ||

Timebandit |

sparky, that's what i was thinking too. if you have longer M8 bolts then you should be able to use them to ease the rotor off. even if you only had 1/4-20 on hand, 1/2" should be enough room to get a wrench in there to hold the backing nut while you turn the bolt, though it will be tight. (Message edited by timebandit on May 15, 2012) | ||

Bartone |

ok! so, I went out and bought a harmonic balancer puller made by powerbuilt and it worked great! it came with 3 m8 bolts just long enough to screw into the rotor and after a few twists the rotor came right out. It looked like there was some locktite on the teeth of the rotor so it made it so much more difficult to pull out by hand. But everything is out, and the modified rotor is in. All i need to do is rent a torque wrench tomorrow and tighten everything up! Thanks for all your help Time. Really helped me out knowing I was doing most things right and it was just the rotor was stubborn. Oh and the timing marks did match up perfectly. | ||

Timebandit |

That's good news. So it turns out that your problem was caused by somebody being sloppy with the loctite? I was worried that that might have been the problem. You shouldn't ever need to use a puller to get the rotor off, and if you do, chances are that somebody used too much loctite and put it in places that it shouldn't have been. I think the stray loctite was the only reason you had the problem getting the rotor loose. Be careful not to do it when you apply the loctite tomorrow. It's probably also a good idea to double check the rotation of your sprag clutch while you've got the rotor off. It should turn one way freely but not the other. You want to make sure that whoever put the loctite on the rotor's teeth didn't get any into your sprag clutch. Glad I could help. | ||

Timebandit |

forgot to mention -- was that red or green loctite that you found on the rotor? be sure to closely inspect your engine to make sure that you don't have any loctite in places that it's not supposed to be! if you had loctite on your rotor, you need to check to make sure that it's not on your sprag clutch, starter ring gears, starter, balancer, etc. needles to say, stray loctite anywhere is B-A-D for an engine. if you find it on any parts that shouldn't have it, get it off with brake cleaner and a wire brush, removing the parts if necessary to clean them. | ||

Bartone |

Yeah the puller was only $20 too! That was suggested to me by one of the hd dealers in the area as none of them sell any tools or lend them. Great help from them huh? It looked like green loctite but it was hard to tell as it was kinda black. And when the starter gear is in place on the sprang clutch it rotates freely in one direction and not the other It doesn't seem like there is excess loctite anywhere else on the gears but I'll double check again tomorrow before I tighten it It was easy to slide the new rotor on once everything was aligned. It should be ok to put 272 loctite on the sprang clutch bolts right? | ||

Timebandit |

the dark green stuff on your sprag clutch bolts is 648. it tends to darken and get brittle when it gets hot, so you tend to see a lot of green shards & flakes when you take the rotor off. i wouldn't use 272 or any other red on the sprag clutch bolts. 272 is for large size bolts. if you put that on small bolts they'll never come off unless you use lots of heat, and that much heat could demag your rotor. then your charging system won't work and you'll be looking at big $$$ for a new 1190 rotor. 2010 service manual still says 648 for the sprag clutch bolts. i confirmed that's what Danny uses when he builds the 1190 motors and that's what he used on the 1190RS rotor/sprag clutch assembly they sent me. I used 272 on the main rotor nut when I put it on. (Message edited by timebandit on May 16, 2012) | ||

Bartone |

Ok. everything is in and running smoothly! the bike really needed a oil change too Thanks for your help again | ||

Timebandit |

anytime. |