| Author | Message | ||

Timebandit |

I'm hoping that someone with a 2009 bike who's blown out their stator and upgraded to the 2008-style low-output charging system from EBR might still have an original/unmodded 2009 rotor lying around. I'm gearing up to do the comparative stator & oil temperature experiments between the stock 2009 rotor and the EBR 1190RS rotor with the oiling mod. Right now, I have the EBR rotor, but I no longer have a stock rotor to compare it to. One option that we would have would be to install all of the temperature measurement sensors and recording gear on one bike, and change rotors. The other option would be to install duplicate recording equipment on two bikes that have the different style rotors, and then take measurements on two different bikes. I think it'll be easiest to compare the results if we do as much of the testing as possible on a single test bed. Besides, installing the temperature measurement gear inside of the bike is fairly labor intensive and involves having a lot of wires coming out of the bike to the recording unit. So that we don't have to embed sensors on different bikes, it would be helpful if we could get our hands on a stock 2009 rotor for testing, so I could swap rotors and do all of the testing on one bike. I'm hoping that someone who's upgraded to the 2008 low-output system when their 2009 stator died might still have their 2009 rotor lying around that they'd be willing to offer for the experiment -- either as a loaner or as a donation to the project. Anyone who would be able to help out would be credited along with all of the other contributors to the project when the results get written up. Please shoot me a PM if you can help. Thanks. | ||

Jwoody |

Sorry, but the user you have selected is apparently paranoid and/or antisocial and does not accept private messages. -J | ||

Timebandit |

fixed. | ||

Timebandit |

Update: Talking to Nightsky and Dualbuells, my other two collaborators, it looks like we're going to need to find some more parts for the experiment. Right now we're thinking about outfitting 3 different 2009 bikes with measurement equipment, one in the northern US, one in the middle US, one in the southern US, to get thermal stator data under different environmental conditions. If anyone has any of the following parts that they'd be willing to donate or loan to the project, they would help us a lot. 1. Stock 2009 Rotor. (without the oiling holes) That's the bowl-shaped thingy that mounts on the crankshaft. I need a stock 2009 one of these to compare to my 2012 1190RS/EBR-exchange rotor that has the oil jets in it. 2. 2009 Stators. Alive or Dead. If anyone has a dead 2009 core sitting on the shelf, we'd like to try to rewind it, embedding two RTD temp sensors inside of the windings to see how hot the stator core gets. If anyone who has converted to the 2008-style setup has a live 2009 stator core sitting on the shelf, we'd like to try to embed a pair of Type-T thermocouple sensors on the outside of the windings to see how hot the stator windings are getting. Optimally, we'd like to have one person build/wind several stators with temp probes embedded inside them so that we can send the temp-logging stator to the different testers in the project who live in different parts of the country. Having one person do the winding with identical parts and construction methods would help to assure uniformity in the test samples. 3. 2009 Rotor Cover. Cosmetics not important -- Rashed-up is OK. Part of the problem we're having right now is that as our number of temperature probes increases, it becomes more difficult to figure out how to place temperature probes inside of the engine to simultaneously measure oil temp and stator temp, and then to get the wires out of the engine case. Routing the wires outside of the case (where the stator wires come out) is a problem. What we'd really like to do is to obtain a 2009 rotor cover that we could drill into, to mount the temp probes and provide a place for the wires to come out. If someone has a take-off 2009 rotor cover (aka: Ignition Cover) that's rashed-up and ugly, we could put it to good use as a "Frankenstein" cover that's been modified for the temperature equipment. Obviously, none of the guys who are participating in the project are interested in drilling holes into their perfectly good ignition covers, so we're looking for a trashy one instead. We're hoping that someone who's laid down their bike and replaced the ignition cover might still be holding onto an ugly old one that they'd be willing to donate to the project. If you can help in any way, please shoot me a PM. thanks. | ||

C818919 |

Im in Alaska and mine is stock | ||

Dannybuell |

Timebandit ~ The wheels are moving!! I'm excited. | ||

Kinder |

Is this a donation or is some compensation being offered? I was gonna try to sell mine to anyone who may want one to get rewound and experiment without risking their own or having downtime on their bike. Need to gather funds for a Saddleman seat!  | ||

Dannybuell |

Kinder & C818919 ~ Timebandit pretty much outlined his test plan for us. You guys stepped up, for Timebandit. Things are moving right along. (Message edited by dannybuell on April 24, 2012) | ||

Timebandit |

COMPENSATION A couple of people have PM'd me about whether or not some sort of compensation would be offered for parts. It's a fair question, so I'll answer it here. No, we're not asking that you compensate us for performing the research effort. Even though some of us have already spent 5-figures on this project, even though we've already got thousands of man-hours in the project, and even though we don't expect to gain any of our time or expenses back in economic gain, we aren't expecting monetary compensation for our efforts. We're just doing this because we want to help solve the stator problem. You shouldn't feel obliged to contribute monitarily to our offset our expenses. Ok, that's probably not what you were thinking when you asked the question. You probably thought that WE should compensate YOU for your used/damaged/take-off parts. That can't happen, for a number of reasons. First, I wasn't kidding when I said one of us has already spent 5-figures on this stator/regulator problem. That's a fact. One person involved in the project who isn't even a street rider has bought a 2008 and a 2009 R for testing platforms -- and he doesn't even ride street bikes! We've had to buy specialized test equipment and supplies, and that stuff isn't cheap. In fact, the test gear makes stators look cheap at $600. Other miscellaneous consumable supplies are expensive too. The proper wire for rewinding a stator costs about $200. Customized, embedded sensors? You don't want to know what it would cost if you had to buy custom-prototype commercial sensors! The proper stator epoxy costs $300 per gallon. Luckily we've had someone in industry step up to contribute some of the analytical gear on a quasi-donation/quasi-loaner basis, so not everything has been out of pocket expense for us. Nevertheless, our out of pocket expenses have been SIGNIFICANT. With that said, there is just no way that we can pay anyone for their junked stators, used ignition covers, or rotors. Insofar as this is a community-wide problem, we are hoping that there will be people in the community who will be willing to step-up with used parts to help us, bearing in mind that we've already spent HUGE amounts of our own money on this problem. We would like to consider the donation of parts as a sort of community participation in helping to get the project off the ground. When it comes to parts, I need to make a few points clear: STATORS If you are thinking about sending us a stator, it doesn't matter if the stator is working, DOA, or has good output at some RPM and not at others. You won't be getting it back. Here's why: For us to use your stator, it will have to pass stress testing. If it passes, it's a good stator. If it doesn't pass, it will have to be de-wound and the core will have to be re-wound. Re-winding a core will cost a couple hundred dollars, minimum, just for the rewinding wire. It's going to take many hours of someone's time to rewind it by hand. Once we have a working stator, it will have to have anywhere from 2 to 4 sensors embedded in it. The embedding process is permanent. Once the sensors are embedded, they're never coming out. We won't be using JB Weld. The proper Duralco epoxy that will be used to hold it all together costs $300 per gallon. As you can see, it takes a lot of money to take a stator, implant sensors, and get it ready for telemetry, regardless of whether it's a "good" stator or a "bad" stator. Once we put several hundred dollars of our personal money into the stator, we can't afford to give it away. Our telemetry-embedded stators are probably going to end up costing more than the cost of a factory stator. IGNITION COVERS We're looking for ignition covers that we can modify permanently to accommodate the telemetry gear. This is a permanent modification that will require the permanent mounting of the stator, and the modification of the housing to allow wires to come out through the side. Obviously, we don't want to go grinding and drilling on peoples' perfectly good rotor covers, so we're looking for take-offs -- preferably take-offs that are already cosmetically blemished, so that people won't care about getting them back. ROTORS Rotors are the one thing that we're not planning on modifying. Those could be returned at your expense if you want them back when we're done with them. In the big scheme of things, we're spending a lot of our own pocket money to solve a problem that effects the entire 1125 community, in order to benefit the entire 1125 community. We don't see any way of ever recouping our investment in this project -- it's our pocket money going down the drain, for everyone's benefit. We don't think it's too much to ask for some people do donate their used/damaged/take-off gear in order to help to make good things happen. The only way that I can imagine being able to reimburse anyone for parts would be if we had some sort of fund-raising drive to do that. I'd rather not have to deal with something like that. I'm hoping that there are enough like-minded people out there who can set us up with some parts to help make a good thing happen. Thanks for considering helping us out. (Message edited by timebandit on April 24, 2012) | ||

Milt |

Some people may not be aware of the depth of this investigation. There is unprecedented chunk of time, treasure and expertise that's involved here. | ||

Hildstrom |

Timebandit: I have enough 16 HML left on my spool to redo my stator if it fails and to do two other projects I have in mind. I can spare 150' for you, which is more than enough to do a rewind. Just PM me the shipping address if you want it. | ||

Timebandit |

CAN-BUS On the subject of data acquisition: we're looking at logging data from our own add-on sensor equipment, but we're also going to need to try to capture other data from the bike that is already being used by the bike's on-board computers. We need to capture data such as Vehicle Speed, RPM, Tcoolant, etc. One way to do this would be to try to tap into each sending unit on the bike, calibrate it, and record it's voltage output. Perhaps a "simpler" method would be to sniff transmitted data between the ECM and the IC via the CAN-bus. It would help us immensely if anyone who is familiar with the 1125 CAN bus signalling protocols could contact me. It would greatly streamline our efforts to record/analyze system data if we were able to capture/de-code the data payload being transmitted across the system bus and dump it onto our logging system. Thanks. | ||

Yugi |

I realized that you're Canadian, even without looking into your profile. | ||

Timebandit |

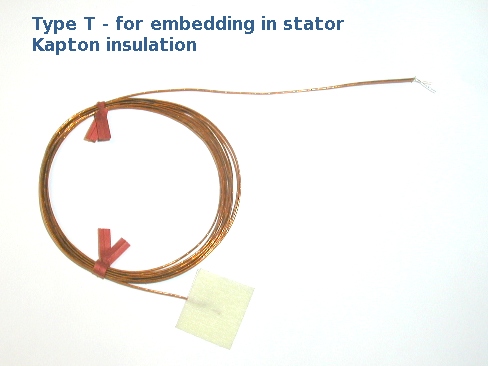

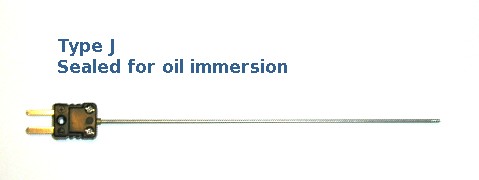

SENSOR PORN I know that you guys like to see pictures, so I thought I'd post a few pics of the sensors that I have on the bench right now, just to show you that we're not kidding about doing this right. Ambient Air Sensor. Type J thermocouple in a custom made, rigid tubular mount, with perforations at the tip to admit ambient air flow. 10-foot Telfon leads.  Embedded Stator Sensor. Type T thermocouple for embedding in stator epoxy coating. 10-foot, high temperature Kapton wire insulation. (In this photo the the thermocouple tip is protected in a sandwich of high temp fiberglass tape.)  Immersible Oil Sensor. Type J thermocouple embedded in the tip of a solid shaft, safety wired to the oil dipstick. Plug-compatible with a 10-foot Teflon extension lead (not shown).   A million thanks to DualBuells for all of his time, effort and materials in making the custom sensors to our specs. . (Message edited by timebandit on April 25, 2012) (Message edited by timebandit on April 25, 2012) | ||

Sparky |

I for one would like to know if temp measured around the stator puck area on the outer cover closely co-relates to internal stator temps. Reason being that its easy to monitor that area using IR temp meters. Would it be feasible to add another sensor to that location? | ||

Reepicheep |

Cool! | ||

Timebandit |

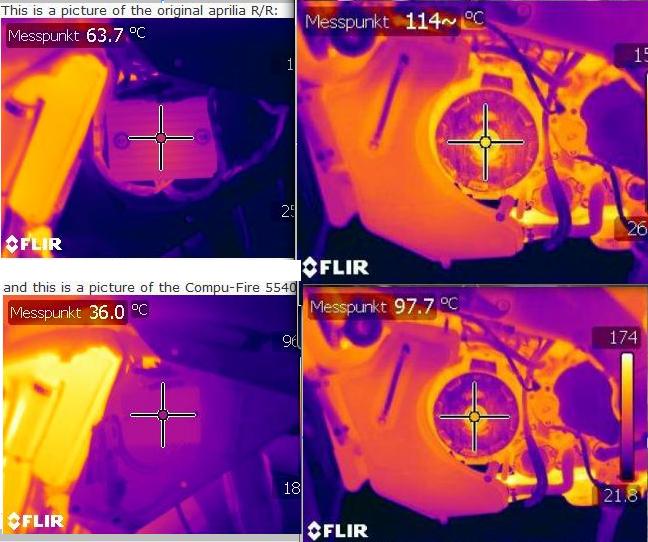

Sparky, that's a very interesting idea. The puck does get pretty hot, but I'm not sure looking at the puck will tell us a lot about Tstator. If you look at the Aprilia heatmap, it looks like the area under the puck is hottest. The way that I interpret the photos, the body of the engine is running hotter than the stator (yellow vs. purple), and that yellow spot in the middle is an artifact of conductive heat transfer from the engine along the crankshaft, to the crankshaft's tip (which sits directly behind the puck), and then radiant heat transfer from the tip of the crankshaft to the puck itself. Notice that the stator itself is a lot cooler in those photos. It's purple.  I'm thinking Tstator would be more accurately measured a little bit off-axis, in the purple areas directly across from the coils. A thermocouple in the puck could only measure radiant heat transfer from the crankshaft to the puck. I'm not sure that it helps us to know Tpuck, other than to confirm that the helicon motor runs damn hot. Presumably a lot hotter than Toil. At the risk of stating the obvious, it would really help to see pictures like this on an 1125. Does anyone have access to a FLIR camera at work? | ||

Dualbuells |

I'll see what we have, perhaps a demo model, I will let you know | ||

S21125r |

Bandit - RE: CAN BUS You should be able to log the OEM sensor data using Tuner Pro (or ECM Spy), laptop and serial cable. Big hurdle would be get the two logs sync'd and consolidated into one data file. Been a while but I think TP has an export to CSV function. hope this helps. | ||

Timebandit |

It does help. Thanks! Right now we have a 4-channel hand-held data acquisition unit for temp logging. One of us has expressed interest in building an 8-channel to 16-channel compact low frequency logger using the embedded Arduino platform. Mounting small items like these on the bike seems feasible. It's pretty hard to imagine securing a laptop to the bike for a 3 hour flight around the back roads to acquire real-world data. I'd prefer a more compact embedded system if there's a way to make it happen. The logistical problem with a laptop is that it's fine in the driveway, but is hard to manage as a real-world in-flight recording system. They're just so darned big. | ||

Dualbuells |

sorry no luck on thermal imaging camera. | ||

Kenm123t |

I can borrow one but you ll have to bring the bikes to Fla. I can shoot a stock 1125r 2009 | ||

Timebandit |

Shooting your bike would be every bit as good as shooting anyone else's, so I don't see any reason to make things more complicated than they need to be. These bikes all have the helicon engine. I was thinking that it would be great to get a shot of the 1125 when hot, like the Aprilia photos. Anecdotal experience tells us that the stators get a lot hotter on a 3-hour ride than they do on a 30-minute ride, presumably because of the prolonged exposure to retained heat from the combustion chambers. It would be interesting to compare thermal images right after a short ride vs. right after a long one. If I had the chance do to this sort of thing, I'd probably want to get side-view images (like the ones above) and an oblique view to show the crankshaft protruding from the engine into the ignition cover. I'm thinking the oblique view would show a VERY hot yellow crankshaft and rotor under the ignition cover. If that's the case, that would tell us whether or not the heat is being transferred from the engine/rotor to the stator, or whether the stator heat is being caused by the voltage regulator. With only the side views, it's hard to tell. | ||

Timebandit |

Update: Photographing Microscope One of our brothers in industry has offered to loan me their industrial photographic microscope to use in examining failure modes on dead stators. It's something that their manufacturing plant can't get by without, so it's going to be a very short term loan. Right now I have a couple of dead stator cores that I'll be examining, trying to figure out if there's a common failure mode. If anyone else has a dead stator core that they 'd be willing to send my way, please let me know via a PM, ASAP. I'm only going to have the loaner gear for a few days, and I'd like to get as much information out of it as possible. I wouldn't be able to return any dead stator cores, as the testing will require some destructive disassembly. thanks. | ||

Dannybuell |

Those IR pictures make me think that an electrical system with some fancy heat dissipation coatings might be a good idea. IDK too much about this, would you start if you were to engineer in this direction? | ||

Timebandit |

some macro photos of a burned stator here: http://www.badweatherbikers.com/buell/messages/290 431/665334.html | ||

Timebandit |

Updated info on the quest for CAN logging: http://www.badweatherbikers.com/cgibin/discus/show .cgi?tpc=290431&post=2218296#POST2218296 | ||

Hildstrom |

Timebandit: Why do you need to solve heat equations, autocorrelation, or deconvolution in real time on the embedded platform? I can't imagine doing those things on an Arduino either, but I also can't imagine needing those results while riding around recording data or sitting next to the bike during dyno runs. It seems like your effort could be a lot simpler and cheaper if you limit the embedded platform's job to logging sensor and ECM data. Can't you perform all of the complex calculations on a desktop computer in post processing (excel, gnuplot, matlab, igor, c)? The floating point calculations in my Arduino C code convert some of the measurements to 8-bit for storage purposes. It would be very easy to eliminate all of the floating point calculations if I were using 1+GB microSD instead of the tiny 1KB EEPROM. Then I could store the as-read multi-byte values and alter them in post processing, which would free up quite a few clock cycles. | ||

Timebandit |

the difference in processors been discussed in detail in that other thread that you referenced. the bottom line is that i want a state of the art processor with modern computational power, rather than obsolete hardware. the board i've chosen is a 32-bit/60MHz platform compared to the arduino's 8-bit/16MHz. the 150x performance difference on FP math is significant to me while the price difference is not. (Message edited by timebandit on May 14, 2012) | ||

Timebandit |

We're still in need of the 2009 hardware that I listed in the 4th post -- especially an ignition cover. If you've got a rashed one laying around, or some other take-off that you'd be willing to donate, please let us know. We're at the point where we have enough sensors to embed that it won't be possible to have them exit the engine compartment without modifying an ignition cover for the wires. If we're going to start drilling / tapping one, it makes sense to do it on a beat-up/wrecked part instead of a nice one. Thanks. | ||

Buellarian |

Still need stators? My second 09 CR stator is fried and in the box ready for shipping |