| Author | Message | ||

Dannybuell |

Lawineer - Sorry, this happens around here. ad hominem again. Someone articulating on anything is not a troll when their perspective, life experiences are not in alignment with yours. The threat of censorship does nothing to promote or maintain civility, it does promote clone like conformity though. Understood? | ||

Lawineer |

Lawineer - Sorry, this happens around here. ad hominem again. Someone articulating on anything is not a troll when their perspective, life experiences are not in alignment with yours. The threat of censorship does nothing to promote or maintain civility, it does promote clone like conformity though. Understood? ----------------------- Yes, but you've got to appreciate the irony of it on Buell forum preaching creative new designs, don't you? edit: typo (Message edited by Lawineer on January 17, 2011) | ||

Lawineer |

>>>> I don't think it's trolling at all . . . I work with top engineers and attorneys here in NYC daily . . . there are some who are, in all candor, better than others. Some of the ridiculous foregoing statements told me all I needed to know. I'll stay on the sidelines . . . . any attempt to discuss this will most surely go the way of the fabled wrestling a pig in the mud joke. Enjoy yourselves and I hope your brakes work . . mine are fine. --------------------------- If you can get one of these engineers to tell me a different set of physics rules applies to heat transfer in the rotor of a car as opposed to a motorcycle or that less surface area will allow for more heat transfer and explain their position (within the scope and context of this "discussion"), I'll happily set my degree on fire. I don't really care what the attorneys have to say  | ||

Jdugger |

> You got it, or rotor mount components. > Except for the specifically mentioned "rotor mounts". Well, I'm basically 100% sure that rotor mounting hardware is just plain steel. In the Erik Buell Racing rotor mounting kit there's a copper washer, a zinc plated grade 2 steel washer (!), a square drive bushing that appears to be chrome plated steel, a (thin) spring steel belleview washer, a tophat bushing, and a zinc plated steel fastener of unknown grade in the kit. That's it. I've been through that kit so many times and been on McMaster even more getting replacement bits for it (when working with the 16.5 wheels in particular, which the kit won't support out of the bag) that I'm pretty dang familiar with it. The ZTL 2.5 pistons are made of titanium, at least so I'm told, so I don't suspect it's those, either. That leaves us back at the rotor. And, Steve's comments. > I'm still scratching my head wondering how anyone could imagine Buell using > highly toxic (illegal) material for the friction surface of a motorcycle brake > rotor. Ask Steve Anderson. He posted, I parroted. Yours is a great question to ask, for sure. That said, I can think of one way, and it's done with stainless steels and copper all the time in other applications: a sandwich. So, the bearing surfaces of the rotor would be SS, but the core would be a different material with desirable properties like heat conduction, or dimensional stability under heat, which stainless kind of sucks at, actually. Again, I don't know. But Steve implied -- stated, really -- there was Beryllium used in Eslick's brake system and a bit less in the production parts planned for the B2. So, if Steve was wrong, so be it. I'd sure like to hear it from him though, since he's the one that was willing to put his name next to the comments, and by all reasonable accounts, he should have been in the know. > I don't see the colors you are talking about in your photo. > What color are the surfaces of the holes? They appear golden hued to me. Look at the EDGES of the rotor. They are gold on the areas around the mounting hardware, and pink, blue, etc, in the fins. As a color reference, notice the color of the compression adjuster of the fork and compare it to the finned edges of the rotor. It's not a microscopic phenomenon here, it's blatantly obvious, you just aren't looking in the right places. The vent holes are definitely pink, blue and purple. The picture sucks, I admit. I'll try and get a better one this weekend. This is by no means the most colored rotor I have produced. This one is pretty new, actually. And, it's been cold outside, with the warmest day I've ridden this one being about 50F. That does make a difference. I'm probably running 5-7 seconds off a race pace the last few times I've been out to the track. Still, I say of you come to ECR and see for yourself. I will show you IN PERSON exactly what I'm talking about. I'm not bullshitting about the brakes. I know the system well, and what it requires to get it to perform at club racing levels. I have 4,000+ laps (yes, 10,000+ miles) of experience at ECR alone in this. I can show you a garage full of wheels (5 sets, I think) with this rotor hardware on it, and I think I still have an old OEM takeoff that's been shagged more than a retired hooker. It's blue and black all over -- the rotor, that is. None of my buddies bikes have rotors that look like mine. Including guys on ordinary UJM sportbike hardware running faster times than me. Trust me, the CMRA is full of guys that whoop my ass without much expended effort! There's a reason I'm a yellow plate. And, that brings us back to what's really the point. Buell's design traded things like weight for things like heat and pad and rotor consumption. | ||

Jdugger |

> In light of anonymous' correction of your false statement, anyone with a brain would figure out that it was either the rotor mounts or caliper components that Steve was referring to. > Your reaction was to go all indignant and flame the person providing truthfull information. VERY bad form. You owe an apology. Blake, The problem is I know really, really well what's up with the rotor mounting kit, and have inside information on the ZTL 2.5 caliper kit, too. That mounting kit is really just plain steel. It's genius is the design, using the top hat bushing and Belleville spring to create a mounting that tended to keep the rotor in contact with the wheel to help dissipate heat and reduce brake drag, while still allowing the rotor to float a bit as the temps came up. So, while it's certainly possible the plan was to use caliper pistons containing Beryllium, certainly the racing upgrade component (ZTL 2.5) did not. I don't owe ANYONE that won't put their name behind their comments an apology. If they expect me to face them, I expect them to face me. | ||

Blake |

Lawineer, >>> 1. Where do you think heat from the brake fluid goes? We were talking about the brake rotor, not the fluid. Not following your point. >>> 2. The cooling from brake fluid (to the AIR) is effectively constant between the two designs, except that the dual rotor design might again have a slight advantage for having two sets of lines, more fluid, etc.  See above. See above. >>> 3. Do you know what convective cooling is? Yes. Scored a 92 on my FE test. My professor, J. P. Holman, wrote the leading heat transfer text of the day, and Heat Transfer was one of my all time favorite undergraduate engineering courses of study. For senior design I wrote a lengthy fortran program for Texas Instruments that simulated convection heat transfer for computer chips. >>> Because that's pretty much how the brake is cooling itself to the air. "Cooling itself"? You mean "being cooled"? There is no "pretty much" to it. If there is heat being transferred from brake disk to air, which there obviously is, then it is only by convection. >>>Convection, conduction and radiation. Those are the 3 basic heat transfer methods. Those are the only mechanisms of heat transfer. >>> Convection and conduction are pretty much the same thing, except conduction is more solid-to-solid heat transfer. Same formula applies (in essence, the coefficients have different names). And the coefficients for convection are infinitely more complex, less accurate, and are subject to a myriad of constraints and pre-qualifications in order to be valid. Convection heat transfer is a science in its own right, vastly more complex. The mechanics of fluids including boundary layer thickness profiles, turbulence, free versus forced convection, edge effects, separation of flow are just a few of the issues involved. Conduction heat transfer is simple. Q=kADT/Dx where Q is the heat flow rate k is the conductivity of the solid material through which heat is being conducted. A is the cross-sectional area of the solid material through with heat is being conducted DT is the difference in temperature from one fast to the other of the solid material through which heat is being conducted. Dx is the length of the material through which heat is being conducted. Convection, not so much... Q=hADT That little "h" is a real pandora's box for anything but the most simplistic convective heat transfer situation. "The convective cooling airflow environment inside an automotive wheel is vastly different from that of a motorcycle front brake." >>> Yes, it is. What's your point? That exactly as Court stated in response to your claim of automotive brake expertise, "Some of the best practice and principles in auto brakes don't translate well to 2 wheeled vehicles." Why? Because the convective cooling environment is vastly different. >>> You posted up some completely irrelevant picture of kinematics. Actually those are free body diagrams which illustrate the balance of forces in equilibrium; statics, not kinematics. >>> In the end, the heat transfer in a car rotor and motorcycle rotor are the same exact physics Yes, physics is the same all over the planet Earth, no matter the subject, no matter the situation. Can you please find a new tune? >>> using the same exact formula. Very doubtful that anyone is using a simplistic formula to characterize the highly transient heat transfer and widly varying fluid mechanics applicable to a motorcycle front brake. >>> Some of the numbers you plug in will be different, but that's neither here nor there... Unless you are trying to engineer an efficient motorcycle brake system, instead of an automobile brake system. >>> and it certainly has NOTHING to do with the image you posted. The image I posted pertains to the post in which it was presented, which had little to do with the details of any heat transfer analysis. Not sure why you are focusing on it. As stated above, the images are free body diagrams illustrating the balance of forces acting on the lower fork leg and brake caliper/bracket assembly. (Message edited by blake on January 17, 2011) | ||

Blake |

>>> I don't owe ANYONE that won't put their name behind their comments an apology. If they expect me to face them, I expect them to face me. I don't think anyone expect much of anything from you, let alone that you need to "face" anyone. Merely a simple apology for your rudeness and admission of error is what I'd expect. You were wrong. Anony corrected your mistaken information. You should have thanked Anony instead of getting all indignant. Very poor character. Pride and ego are terrible taskmasters. (Message edited by blake on January 17, 2011) | ||

Blake |

>>> And, that brings us back to what's really the point. Buell's design traded things like weight for things like heat and pad and rotor consumption. And race wins. Not a bad trade for a racing machine. | ||

Blake |

>>> The problem is I know really, really well what's up with the rotor mounting kit, and have inside information on the ZTL 2.5 caliper kit, too. Color me skeptical. >>> That mounting kit is really just plain steel. It's genius is the design, using the top hat bushing and Belleville spring to create a mounting that tended to keep the rotor in contact with the wheel to help dissipate heat and reduce brake drag, while still allowing the rotor to float a bit as the temps came up. "Plain steel" you say? >>> So, while it's certainly possible the plan was to use caliper pistons containing Beryllium, certainly the racing upgrade component (ZTL 2.5) did not. Steve's comment was in regards to the system being used on Danny Eslick's racing machine versus what was soon to be offered for sale on the Buell next generation Baracuda production superbikes, dubbed the B2 machines; the production machines having less beryllium. "All the improvements that had been made to Danny Eslick's front brake system were made to the B2s -- it (production B2) literally had rotor mounts and rotor that were essentially identical in form to Danny's, though there was a little less beryllium in the production parts." No beryllium in brake disk so... really it's not that tough. You don't have production B2 brake parts do you? | ||

Dannybuell |

| ||

Jdugger |

> You should have thanked Anony instead of getting all indignant. Very poor character. Pride and ego are terrible taskmasters. You were the one that didn't want to make this personal. I admitted my error back on Thursday. I'm certainly not going to be thanking anyone not willing to put their name behind a statement. This ain't pride, pal. It's having the knowledge to know I'm absolutely right about the core issue that started this thread, and that's the ZTL2's disadvantage when it comes to heat. Why do you insist on bringing up this ancillary detail? I know! It's all you've got. Even if Steve (and as a result, me) are dead wrong about the Beryllium, there's still the validity to Steve's statement that Eslick's front brake was anything but stock. Unless you are suggesting Steve's post was incorrect? Certainly that's a possibility, though I know Eslick wasn't using OEM components, so it's really unlikely. I'll offer again: come out to ECR. Other than Oak Hill which is closed, it's the closest track, or nearly so, to you. I'll even give you a guest pass so you can ride, too, and I'll demonstrate to you exactly what I've been talking about. Oh, and bring your bike. I wanna give those rotors a proper break-in and make the technicolor rainbow on them. You can take them home as street cred. Maybe we can work in your trail braking skills while you are here?  > And race wins. Not a bad trade for a racing machine. Really? The ZTL has been beaten as much as it's won, a few times over, really. And, frankly as a component of an overall platform, ZTL is just one of many gears in the works that lead to a successful platform, anyway. I think you have to approach the idea that the ZTL isn't necessarily *better*, it's just a unique solution to the problem with trade offs. The major disadvantage to the system is heat. It causes fade, it causes brake drag, and so on. | ||

Jdugger |

> You don't have production B2 brake parts do you? I might. The Erik Buell Racing mounting kit was to become the OEM in 2011 had Buell not been shut down, and on the B2, so it was rumored. I can't confirm that, but seems to be what I remember hearing. > "Plain steel" you say? Pretty sure -- it's certainly ferrous. And, when I say "plain steel" I'm talking about typical hardened fasteners like one would by from a quality supplier like McMaster. Nothing exotic. Lord knows I've got a few handfuls of them around. Which part do you want me to have tested to find out exactly what it is? At this point, I'd be more willing to accept that there's no Beryllium at all in the brake system and Steve had his facts crossed before I could imagine what part of the rotor mounting kit contained it. It just doesn't make much sense to have light metals like that on the rotor mount kit where shear and compression loads are high. A lesson I learned once before: I tried a hardened/anodized aluminum washer between the rotor and rotor bolt. The washer actually crushed under test braking loads (not even race pace) and let the rotor get all floppy. I ran the same tests with grade-5 stainless washers. Same result, but it took about 10 track days to achieve the same wear. Hardened AL isn't much softer than Beryllium, and so I really don't see a place for that material in the rotor mounting hardware based on my experience. Now, I use the steel washer, Belleville spring washer and a titanium rotor bolt. No issues, but the drive bushings still wear out quickly and score the insides of the bearing edges of the rotors. Apparently that's pretty common. So, really, the only place I can imagine is the caliper pistons. Nothing else makes sense at all as a possibility if the rotor can't have it. | ||

Blake |

Logorreah. >>> The major disadvantage to the system is heat. It causes fade, it causes brake drag, and so on. Not on Danny's bike or apparently on the other championship machines winning against top competition. Oddly enough, I've rarely found any disadvantage in winning. Given the decades of development that has gone into the conventional dual disk brake systems, it is truly amazing from an engineering perspective that in teh span of three short years and coinciding with the advanced racing success of a MUCH faster machine, we have the rapid development of a much improved ZTL braking system. From standard six piston ZTL-1 to championship winning ZTL-2.5 in three short years. Imagine the possibilities. Or go around campaigning on obsolete and insofar as street use is concerned inaccurate information shouting to folks that the ZTL has HUGE heat problems? What is the purpose? The ZTL-2.5 that was set to enter production on the B2 Baracuda was ready to rumble and addressed the even the most demanding racing scenarios with almost imperceptible changes to the ZTL-II configuration. To me that doesn't spell out "HUGE" problem. It indicates a normal, run of the mill challenge to a relatively new and evolving revolutionary design. No? I mean if it was such a "HUGE" problem, how is it they managed to overcome it through relatively minor revision to the design? | ||

Blake |

I'll happily take you up on your offer to take a turn at ECR. I've never been there. Oak Hill being closed really SUCKS!!! Had my brakes faded there once in practice, pads were worn out. New pads, no problem. Michael Sanchez in his prime even took the Cyclone for some laps there one afternoon. No brake fade even at a 1:30 pace there. I was doing 1:35's. My race winning buddy Keith has run his XB Lightning there many times. The six piston ZTL has never let him down. I think some folks are harder on the brakes than others. Matt (Trojan Horse/Adrenaline Moto) in England had experience similar to yours on his race team Buell, but that was with the six piston version. | ||

Jdugger |

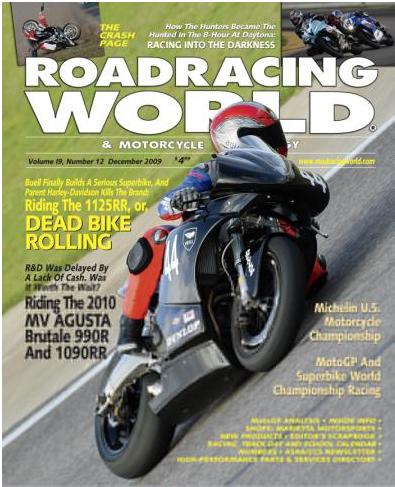

Go go fanboi!  Remember this article?  It was an honestly pretty dang good review of the 1125RR. There were a fair number of comments in the article about the brake drag. You know what brake drag is and what causes it, right? Eslick's bike had seriously non-stock components on it, each designed to address heat dissipation issues. To say he didn't have issues with heat is just crazy. Relatively minor design changes? You mean a totally different hardware mounting kit design and a completely different rotor? | ||

Jdugger |

Oak Hill is too tight and slow to really stress the brakes. Plus, if you were on the XB platform I'm not surprised at all. Those things just ain't that fast. I never faded the brakes on my XB, either, but they aren't doing 135 down the back straight at ECR into the panic stop that is turn 7. ECR's turn 1 is a 100+ to 50 or so braking zone. Turn 3 about the same, but you have the grace of even camber. Turn 6 is a downhill, double apex, 115mpg to 60 or so braking turn. Turn 7 is a 135+ to 45-50 mph braking panic. Turn 11 is a lot like 3. You are good on the brakes at ECR, or you are last. (Message edited by jdugger on January 17, 2011) | ||

Jdugger |

> I'll happily take you up on your offer to take a turn at ECR C'mon out. Saturday and Sunday both looking cool but definitely rideable. You know how to reach me. | ||

Court |

_ >>>>>I wanna give those rotors a proper break-in and make the Technicolor rainbow on them. _______________________________________ Unrelated to this dialogue. . but I always laugh whenever I read that. In 1999 there was a major national company who hired one of the NY Yankees stars as a spokesperson. Part of the gig was that they were giving him a Harley-Davidson "Night Train" as part of the compensation. It was to be awarded to him on national television live from Macy's on Herald Square here in NYC. The bike went to the custom painter and, prior to being taken to Macy's, I was asked to do the "official" test ride to sign off on the bike. The fellow and his agent were there when I arrived and got kinda pissy when I took time to put on all my gear. "Dressing for winter?" . . asked the bone headed manager . . "No. . an early fall" was my response. "Well, don't take too long, our time is valuable". I think it was just his attitude. Anyway . . . I left with the bike showing about 3 miles, got it into 5th, pinned the throttle and used the front brake (bold move on HD's part calling it a brake) to modulate my speed. It took almost no time at all for the rotor to be glowing so intensely cherry red that you could nearly see through it and the lever was flopping limp against the right grip. Now . . and this may tie into our instant discussion . . . I figured all this would clear up and go away in a matter of minutes. Not so . . it took better than 20 minutes. I went back . . gave them the standard "bandanna and chaps" line about how damn powerful the bike was and how I could barely control it . . and loaded it in the truck for them. I'm sure someone, somewhere likely asked him about those brakes. Safe to say that the Night Train exhibited significant heat issues. I still feel a bit guilty. | ||

Jdugger |

That's pretty funny. I had no intention of cheating -- it hadn't even come across me to take his bike and run the gas and the brake at the same time. That sure would make it easier! I've been sitting over here thinking: I wonder how he's going to feel about me wanting to spoon a decent front tire on his bike so I can rail on the brake? | ||

Fast1075 |

I love discussions like this...it shows who the thinkers are. I have been dealing with heat transfer for over 30 years..but i'm self taught so I'm not qualified to say anything...but I can't help but wonder how much surface area the rotor really has...and why the "color" of the rotor seems to alter it's ability to shed heat. Wonder what Smokey Yunick would do when posed these questions??? But then again I am an uneducated though curious person. Who sometimes likes to stir the pot  . . | ||

Jdugger |

> and why the "color" of the rotor seems to alter it's ability to shed heat At temperatures below glowing red, I don't think it does. Color, at least in stainless steels, is more an indicator of the temperature the material achieved. | ||

Jdugger |

> but i'm self taught so I'm not qualified to say anything. Why not, didn't stop me  | ||

Blake |

You keep characterizing me as a "fanboi" or "fanboy". Is there something about the following that you don't agree with?... Given the decades of development that has gone into conventional dual disk brake systems, it is truly amazing from an engineering perspective that in the span of three short years and coinciding with the advanced racing success of a MUCH faster machine (1125RR/1190RR platforms), we have seen the rapid development of a much improved ZTL braking system offering multiple pounds in reduces unsprung mass; it's evolved from the standard six piston ZTL-1 to championship winning ZTL-2.5 in three short years. Being an engineer, I may have more appreciation for such accomplishments. | ||

Blake |

>>> Relatively minor design changes? You mean a totally different hardware mounting kit design and a completely different rotor? Yes, that'd be minor. Can't tell the difference from 20 feet away, same caliper, same rotor just thicker with added fin details. Yeah, from an engineering perspective, I'd call that minor. Major would be having to alter the basic configuration, change diameter, swept area of pads, different caliper or the like. Just wondering, what would you consider minor? According to your comments, about every new Japanese repli-racer includes a major brake system redesign. Nah, they just refine it, change some connection hardware, not much too it. The loads and primary specs stay the same. | ||

Blake |

>>> C'mon out. Saturday and Sunday both looking cool but definitely rideable. Rain check! I'll be in Dallas, but can't get away for fun, unfortunately. Sure is nice of you to offer. | ||

Fast1075 |

I was talking on a microscopic level about the surface area...it depends on the finish...not only does color indicate to a degree the temperature the part has seen (depending on the material), but indicates to a degree the radiant capabilities..."color" as we see it is the spectrum re-radiated by the surface...the remainder of the spectrum is either absorbed or is of wave lenght too long or short for our vision to "see" it. In the end, it is all a trade-off of effectiveness vs cost anyway...If you can't remove enough heat by convection, or radiation (did you know on stock cars on some road courses, the radiant heat from the brakes will kill the tire if there isn't additional cooling air to cool things down?)...you only have conduction left...the caliper is working overtime trying to cool itself from the heat transferred by the pads...(they have to handle half of the gross heat load)...so you either find a way to improve the cooling or build the system from heat impervious material$...the engineering is another matter, but the concept is easy. I'm no brake engineer, but the same concept of using sodium filled exhaust valves to help transfer heat might work, or it just pain old might be too expensive...like the carbon/carbon rotors in F1...or other exotic materials. | ||

Jdugger |

> Yes, that'd be minor. Can't tell the difference from 20 feet away, same caliper, same rotor just thicker with added fin details. > Yeah, from an engineering perspective, I'd call that minor. Well, if that's your criteria, the 1190 and 1125r have the same motor!  It's a significant engineering change. There's not a single similar component I can think of between the two different mounting kits, and of course, the rotors are of a different design. The mounting approach is totally different, too. In the OEM kit, the mount bolt is also shouldered and holds the drive bushing. The rotor itself uses a compression spring inserted into the wheel that pushes the rotor away from the wheel. In the Erik Buell Racing kit, the rotor is held close to the wheel using a Belleville disc spring washer. The primary bolt passes through a top hat bushing that handles the load of the drive bushings, and serves to offset the wheel casting so the underlying copper heat sink washer has a lot of contact with the rotor and wheel at the same time. Honestly, it's a completely different design. | ||

Blake |

Okay, you convinced me. Wore me out. It's a shame the production bike didn't fare similarly wrt H-D. | ||

Dannybuell |

Court - "No. . an early fall" LOL! | ||

Court |

>>>Court - "No. . an early fall" LOL! Yeah . . see . . even if ya don't like me ya have to admit I've a quick wit.  |