| Author | Message | ||

Smitty1125r |

I'm looking for a front and rear cog (sprockets) with belt for a 1125cr. I'm trying to "regear" my 08'r. I already have the oversized pulley, just need he cogs and belt.nI have a few mods but im looking to finish the bike this year, Thanks smitty1125r/ | ||

Dman |

Ah yes, the ole re-gearing project, I did this to my 08 & it's the best mod ever. Here's a link to my posting about it. As you'll see i tool guidance from Erik Buell Racing, well worth the effort. Happy to help if I can with info, etc. http://www.badweatherbikers.com/buell/messages/290 431/569038.html | ||

Puzzled |

The front pulley is the same from the R to the CR. In Dmans thread he has a list of parts for the traditional swap. Search the forums and find a thread where the conversion was done by Mike1125 without changing the swing arm. The key to his success was an over sized idler pulley. I did not change my swing arm either. I went a different route and fabricated a tensioner as opposed to a idler. With my two different rear sprockets, belts and three front pulleys I have six gear ratios to choose from. | ||

Jdugger |

> The key to his success was an over sized idler pulley. Just keep in mind that's likely to have some unintended consequences at the extremes of swing arm travel. That whole set up is a pretty complicated system of equations. | ||

Smitty1125r |

Puzzled- If you dont mind me asking how hard is it to make another tensioner? I think that would be ideal, different gearing options would be amazing. | ||

Dman |

I was looking at going with a custom idler myself, tried contacting a guy here who had a guy do his, and a couple other contacts, non worked out in getting something going. When I talked (emailed) Erik Buell Racing I came to the conclusion to do it the way they did. Essentially if it was a good idea to only do the idler & that was all, then Buell wouldn't have spent the $ & time on a whole other swingarm setup ... at least that's the kind of response I got from Erik Buell Racing - they said the only way for the drivetrain to work properly as designed was with a swingarm swap, that there's a "right way to do it" and then certainly anyone can try it however they want to try to make it work. But ... they have warranty coverage etc to worry about, so I take it all with a grain of salt, but they have more knowledge on these in their pinky than I have in my whole body, so. I just decided based on the swapping of parts & deal I got, it was only a few hundred bucks & I could do it in a couple hrs & have it setup very reliably for me. But if I could get the custom idler option done,I wouldn't have worried much about it, again there are at least a few people running this way with no probs I've heard of. My ideal was a chain setup, but holy shnikey's the cost on that. But I won't get into the whole chain vs belt thing, I'm an old dog, what can I say. | ||

Cherry_bomb |

what's with the ecm-software. last time they flashed my machine, i've seen that there is a different software for r's and cr's. also, ebr sells different types of ecm. i thought that these are different fuelmaps for difference in gearing? or is there another reason? | ||

Dman |

Yes, it's for the gearing, Erik Buell Racing sells an R and a CR ECM, they say the only difference between them is the speedo calc due to the different gearing. They had me get a Erik Buell Racing CR ECM for my 08 R to correct my speedo & get their ECM tune all in one. Did I mention I love Erik Buell Racing. - BTW, I'm only talking about Erik Buell Racing ECM's. My understanding is that for dealer flashes there are other subtle differences by yr to accomodate for the injector difference, Erik Buell Racing doesn't, but others know faar more about the flashes than I. | ||

Smitty1125r |

Puzzled- How much would one of those tensioners you fab'd up cost? seems like the way to go for me... | ||

Duggram |

I have an over-sized idler pulley I bought from mike1125 that I want to sell. I paid $150 for it and never used it. Mike tried it to make sure it worked. I have a chain drive conversion and don't need it. | ||

Nillaice |

i wanna explore the alternative methods and the details of reducing the final drive ratio. looking at the production #'s and it seems more common for R owners to (1) exist, and (2) desire to reduce thier final drive ratio, while keeping the maintenance-free belt. i like the idea of replacing the drive sprocket with a larger/more tooth count, and replacing the idler with a tensioner. Puzzled, you have my attention ... please go on | ||

Puzzled |

To seperate the two halves of the compensating sprocket the ring that keeps the belt from walking has to be slid down.  This is what you will find inside, the equivalent of a cush drive. On mine all of the rubbers were broke.  | ||

Puzzled |

Stripping away the unwanted pieces!  I used a cut-off wheel to remove the lugs that held the cush drive. The material is hardened but not to the point where it could not be cut.  Turning down the diameter which will serve as the outside retaining ring for the new pulley.   Finished that and now on to cleaning up where I cut the lugs off.  | ||

Puzzled |

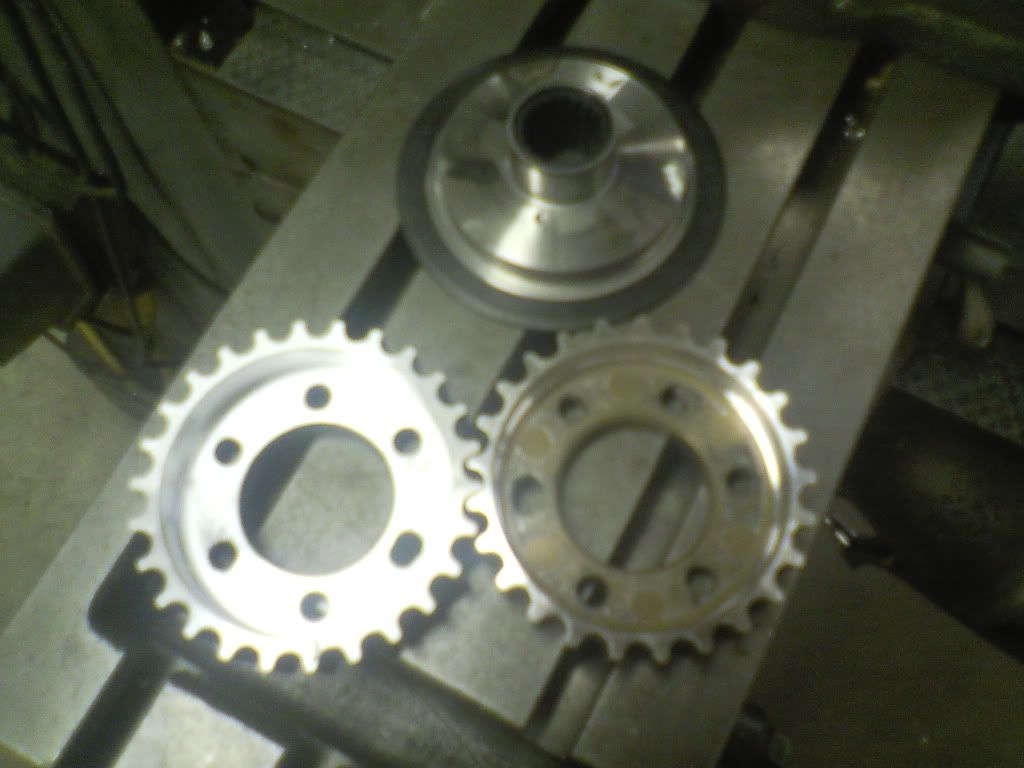

A few passes to insure that the surface was flat and square to the outside lip.   The pulleys were cut to match the original width of the compensating sprocket.  As you can see there is a difference in diameter from the original center hub and the pulley center hole. There is also a height difference from the mounting flange on the pulley stock to the original cut up piece of compensating sprocket.   | ||

Puzzled |

Turning down a piece of stock to make the spacer needed to close up all of the differences.....   The spacer dubbed the "retaining ring".  No more gaps/space differences.  | ||

Puzzled |

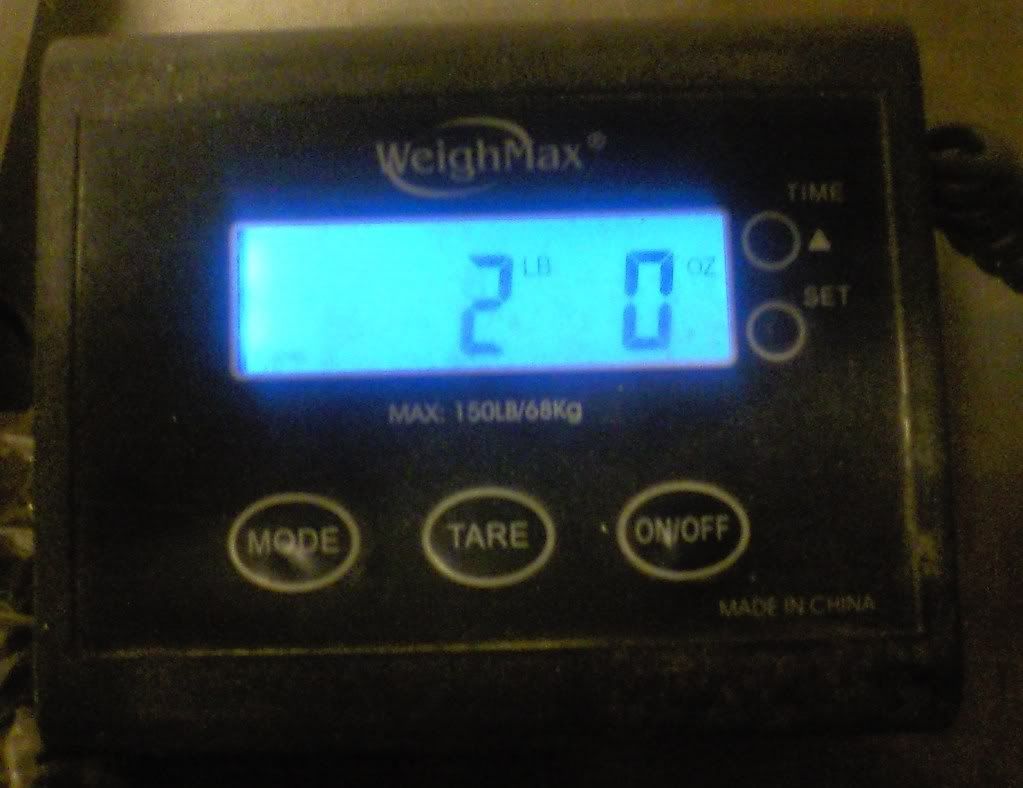

The original center piece of the compensating sprocket. Cut the flange off.  Turned down to maintain the original thickness of the compensating sprocket as well as maintaining stock bolt length.   The aluminum piece on top is the belt retaining ring. It will get drilled along with the flange which also gets tapped and drilled for 7/16" dowl pins. So I'll have 3 bolts holding the assembly together as well as 3 dowl pins to drive the pulley. The new assembly with the 27 tooth sprocket weighed in at 2 pounds 6 ounces. That is 2 pounds 8 ounces lighter than stock. What affect do you think that will have on the motor spooling up? Rotating mass!   | ||

Puzzled |

The 25 tooth magnesium pulley weighed in at 2 pounds even. 2 pounds 14 ounces lighter than stock!   I machined all three pulleys so I can maintain stock gearing as well as dropping two teeth in the front. I may consider machining one more pulley, a 28 tooth. This may help with some top end for the MPH runs. 27/70 = 2.59 to 1 Stock R gearing 26/70 = 2.69 to 1 (4% change) 1 down on trans sprocket 25/70 = 2.8 to 1 (8.3% change) 2 down on trans sprocket After drilling and pinning the the hub next up is seeing how the belt and tensioner will take these changes. If there isn't enough movement on the tensioner to take up the two tooth change I may make a slightly larger idler pulley. | ||

Puzzled |

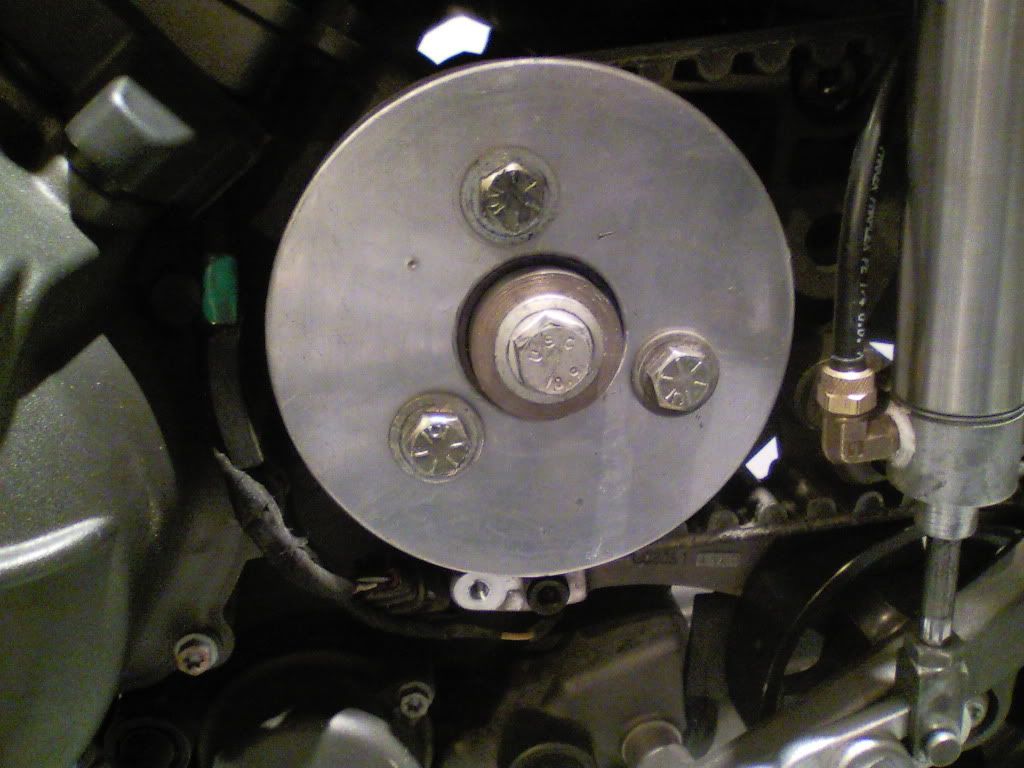

My intentions are to replace the idler pulley with a tensioner pulley. I have some preliminary belt tension readings from the stock set up and now I'm trying to convert them over to what the tensioner industry uses. As a quick test I bolted a manual XB chain adjuster to the bike (with the sprocket removed). That will definitely take the slack up. Now it is a matter of getting the tension correct with either an elastomer or spring type self adjuster. For my application a manual adjuster is just fine as my suspension is strutted for drag racing hence no swing arm travel. However I would like something that will adjust on its own for the various pulley sizes while maintaining sufficient tension.     | ||

Puzzled |

Here is the 27 tooth pulley pinned and bolted with the belt retainer in place.  I finished my tensioner project this week. The first one wasn't quite strong enough so I used the next one up which seems to be just fine. With 11 runs on the bike tonight everything is working as it is suppose to.  | ||

Puzzled |

| ||

Puzzled |

| ||

Puzzled |

9-10-10 60 FT. 330 FT. 660 FT.660 MPH. 1000FT. E.T. MPH 1.525 4.136 6.366 109.950 8.320 10.002 132.740 1.532 4.172 6.411 109.210 8.378 10.071 132.090 1.512 4.149 6.396 109.050 8.369 10.071 130.820 1.528 4.182 6.427 109.120 8.401 10.101 131.140 Oh so close to a 9. There were 4 oil downs tonight so I got very few runs in in comparison to most nights. My first two runs were not so exciting as the air shifter wasn't cooperating. One run I just aborted and the other I foot shifted to the tune of a 10.338. With that fixed my times were dropping. I was concentrating of going full throttle as soon as I could. I had my shifter set at 9500 tonight, a full one thousand lower than where I have been running it. My next time out I'll try the shifter with a little less/more RPM's. __________________ | ||

Puzzled |

My 76 tooth pulley and CR belt are here. That is my project for the weekend to get them mounted. I'll change the front pulley from the 25 to a 26 with the 76 rear. That will net me a 2.92 to 1 ratio. | ||

Nillaice |

stock R 27/70 =2.59258 stock CR 27/76 =2.81481 so one of your 25t pulleys would put an R at 2.80 and it would put a CR at 3.04 please tell us more about your tensioner. i see you have it mounted using the GP shifter mount/pivot bolt hole... it is a 'tensioner', not an 'idler', correct? is it sprung or fixed/stationary? | ||

Nillaice |

'it i only had a | ||

Fresnobuell |

Anyone interesting in swapping your CR gearing for my R gearing? PM me for a possible winter project. (Message edited by fresnobuell on September 18, 2010) | ||

Puzzled |

Nillaice you are correct. I'm going to try the 76/26 first (2.9230). That seems to be a good choice of gear ratio for our bikes. On paper it should have me going through the traps in fifth gear close to red line. The tensioner is an off the shelf Lovejoy/Rosta Elastomeric Tensioners, SE18 if I recall correctly. ***Deflects Up to 30 Degrees Either Side of its Neutral Position Allowing a Pretension Force that Self-adjusts an Idler to Everyday Elongation of Chain or Belt while Dampening Vibration in the Drive Four Rubber, Inside Base Isolate Tensioning Arm from Contact with Base and Provide Continuous Resistance Eliminates Slap and Vibration while Minimizing Drive, Bearing and Shaft Wear, Keep Chain and Belts Taut Preventing Uneven Drive Surges and Power Losses*** (Message edited by puzzled on September 18, 2010) | ||

Nillaice |

Fresno, that would be ideal for alot of R owners, myself included. i've been spamming it on here, in the want ads, and in a few PM's but i have yet to find someone willing to swap with. i almost had a guy comit but backed out teh week before homecoming .... -sigh- i've almost given up hope (Message edited by nillaice on September 18, 2010) | ||

Dcmortalcoil |

There was a big discussion in the XB forum regarding whether spring loaded pulley would be good or not. It discussed about the original Buell design maintaining constant tension throughout the swingarm movement. Changing the belt length and a large pulley would likely change the geometry necessary to maintain the constant tension throughout the swingarm movement. Maybe a spring tensioner with the larger pulley might work. Throwing in some options. | ||

Puzzled |

I can't speak for a spring tensioner, the elastomere has 82 runs on it so far. I mounted the 76 tooth pulley and the 149 tooth belt tonight without any problems. It may be a few weeks before I get to the track to test it though. Tomorrow there is an 1/8th mile track running however they don't hand out time slips, grudge run type racing. | ||

Nillaice |

well, anybody ahve anything else to say about this topic? puzzled; any more updates? pics of your elastiometer-thinkgy-mabober? tips/advice/heads-up? | ||

Puzzled |

Pics are above. 82 passes on it with 1.51 60' times and 131-138 trap speeds. That is enough proof for me that it works. I have not tested the 2.92 gearing yet as the local track was not open last weekend. This Friday I plan on hitting the track. | ||

Dman |

Puzzled - this is off topic, but in visiting the thread a 2nd time I gotta mention this. I generally think the 1125's don't photograph well, I think in person they're mean and sexy, but I see pic after pic, including professional ones, that just make it look awkward. Your pics at the track are awesome, whether it's the launch, the angle, whatever, in those pics the bike looks IMO like it does in person, mean, PO'd, I love 'em. Thnx for posting those, I'm snatching them for my pic library. Sorry to hijack, a little. |