| Author | Message | ||

Red_sonja |

Has anyone replaced the semi-hard oil cooler lines with braided SS. Say Aeroquip Hose and Fittings. I am very interested in doing this even if I am the first. Just wondering if anyone knows why this couldn't/shouldn't be done. OK, OK, the purpose is not for performance but aesthetics. | ||

Froggy |

The XB's come with SS lines, I never noticed on the 1125's what they had. | ||

Joshinga |

yet another HD budget cut | ||

1_mike |

Partially because hard lines are much cheaper to make and assemble. And it seems lately...don't leak like SS Braided line. I've had Earls (rubber) line split in a straight section. Another tear at the fitting rather than just have the fiitting cutter, just dig into the rubber like it's supposed to. These lines are only about 16 months old..! IF...I were going to replace my hard lines, I would ONLY use the Teflon lined Braided line. This also has the advantage of using the Stainless fittings.. Mike (Message edited by 1_mike on April 05, 2010) | ||

Captain_america |

Good Idea Red. I'm up for it. I always thought they were ugly too... | ||

Red_sonja |

By my rough measurements, both lines would be 11". I would get the Teflon lines for sure. I respect Aeroquip Hose and Fittings from my racing days. If someone beats me to it, please do a how to. Otherwise in a month or so, i will tackle the job and get good pics to go along with the story line. | ||

Smoke |

i did my race bike after the hard line cracked after a runoff and slide in wet,soft grass and ground. the mud packed in that side so tight it cracked the fitting going into the side of the engine near the filter. the hole size of the hard line is similar to an AN-8 but the threaded holes in the block and cooler are AN-6. anyhow i had some AN-6 leftovers in the salvage area of the shop that i cannibalized and fit to the bike. i have been meaning to get some AN6to8 reducer fittings and bore the holes to -8 size and upsize the lines but have yet to have a problem with the -6's. send an email to tim @ arrowaviationco . com and i will forward some pix. tim | ||

Captain_america |

The company I work for carrys all of Aeroquip's products so it would be dumb for me to not just do it and get those ugly hard lines out of the way. I will hit it with some black nylon braided hose (still capable of 350 working psi) and some of the -8 to -6 reducers. Does anyone know what the oil pressure in those line is? | ||

Johnnys999 |

I'm glad Red brought this up, I can't believe Buell allowed those things into the final design. There might be an alternative, covers. I was talking to the owner of Motowheels some months back about Buell upgrades and he mentioned it. Nothing more was said about it so I'll follow up with an email. I hope he didn't mean something like those funky corrigated tubes that cover the 02 wires from the Lambda exhaust sensors on the right side of the motor. | ||

Captain_america |

Does Anyone know what the threads of the fittings are? metric or standard? They are an O-Ring fitting I know that. They are surprisingly easy to pull apart... | ||

2009cr |

I'm game if someone puts together a kit. I've wondered about the same thing. | ||

Jens |

You need to remove the fittings on the oilcooler and engine and replace it with fittings M14 x 1,5 to (as an example) DASH 6. From there you go with the lines. ! At the engine and oilcoolerside use conventional aluminium or copper washers, not the stock rubberrings ! They work only with the OEM fitting. http://www.pegasusraceteam.com/assets/images/db_im ages/db_Buell_1125_R_Experimental_241.jpg Jens | ||

Captain_america |

Thanks for the info Jens, Why can you not use the same type of o-ring straight thread fitting like the OEM? | ||

Jens |

Capt.america, if you have in the USA a connectionsystem for it, of course no problem to go with the new hose direct to the OEM fitting (what works very well). Here in Europe I havent seen an system that connect a steelbraided or teflontype hose to this "clipsystem". If you found something, let me know. Jens | ||

Sknight |

I was wondering why, but man that looks hot as Hell! New project! | ||

Captain_america |

Oh no. Sorry Jens, I must have miss understood you. haha I was planning on going with something like this:  I wish you could get a -8 An like this though:  Those will seal to the oil cooler and engine with the O-ring like the factory fittings do. I wish they were black.... | ||

Crackhead |

usually, hard lines will flow more then rubber lines if the ID is the same. Also, the ID can be kept more constant with hard lines to match the engine/ oil cooler openings. Rubber lines require a hose barb which will reduce the ID of the line and thus reduce flow. Plus, hard lines last longer then rubber lines. | ||

Anonymous |

The thread pitch for the face oring boss to male AN-6 fitting should be 9/16-18 not metric. Both the engine and oil cooler. EBR is using -6 fittings and AQP hose on the superbike oil coolers. The purpose of the Jiffy Tite fittings and hardlines on production bikes was to put end to leaks, weeps, and seeps at all oil line joints. XB's use the same fittings as well as V-Rods. They work very well in their intended environment. Contrary to uninformed opinions here the fittings are neither "cheap" or of less quality than flare fittings, nor are the associated oil lines. Such changes were driven by quality improvements, not cost. Back to my new job designing toasters  . I miss motorcycles. . I miss motorcycles. | ||

Captain_america |

Thanks Anonymous, Any thoughts on the flow characteristics? Lemme see what size AN I have that has a 9/16-18 O-Ring on the other side. That is definitely the more common size instead of the metric. | ||

Captain_america |

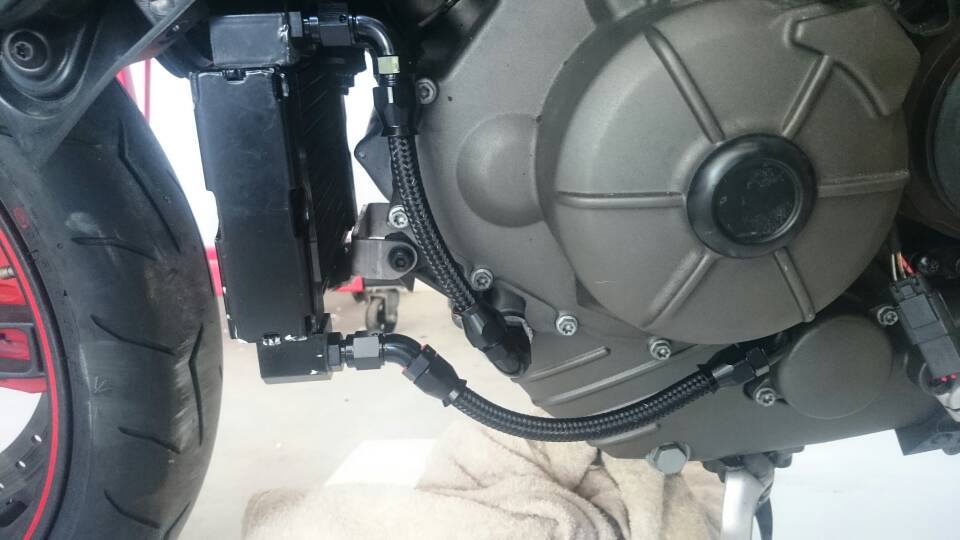

Ok, I did it, She's complete, jobs done, lol. Here's how I did it. THANKS ANONYMOUS!!! For the thread confirmation. It IS a 9/16-18 thread pitch and a -8 line, sooo I started with a -6 to -8 flare reducer, below.  And noticed how it reduced the inside diameter.  Thought, "well I don't need the -6 flare so I'll drill it out to the -8 ID with a 25/64" drill bit.  Then, got some Black -8 line and put everything together... There were two ways to route the lines, and I chose the bottom because I didn't want the line sticking out far from the motor and the stock lines did a little droop anyway... Not Good   Good   Comparison  Did I just one up the Pegasus Race Team? I think so... | ||

Cherry_bomb |

may i have your old lines? | ||

99buellx1 |

Kit time! | ||

Captain_america |

Sure! I could do all black or red and blues with SS line or any above combination... | ||

Froggy |

That is beautiful! What is involved (in terms of time, tools, effort) with doing the swap? | ||

Jens |

As long you live as long you learn (-: I used 14 x 1,5 because I was sure the bike is 100% metric, did not think about recycling of the XB fittings... Jens | ||

Dennis355 |

Do you have part numbers ? All I can find is the metric parts. | ||

Sknight |

Something I got to thinking about today, since that's modifying the oil system I wonder if it would cause issues with warranty. I know it won't reduce oil flow any but we have all seen how HD is starting to act. | ||

Captain_america |

@Cherry, PM me for the stock lines. @Froggy Time: my lunch, which is about an hour. Tools: 1", 7/8" 13/16" wrenches, pick (to get those green clips off the stock fittings), drill with a 25/64th's bit, and a vice. Effort: It's pretty easy to do I think, but its not my first time making up fuel/oil lines either. And the stockers come off extremely easy. Just lay the bike over on its side and you don't even loose any oil! @Dennis355, I work @ Professional Products, and they make everything I used except for the line itself which we get straight from Aeroquip. Head to their site and take a look at the fittings www. professional-products .com, I used PN's: 16009 x 1 16016 x 3 16353 x 4 I reused the O-Rings | ||

Polish_assassin |

Question? Why not use all -6? If you got -6 coming out of the cooler and the engine then why do you need -8 lines connecting them? Please excuse my ignorance if there is something I'm missing here. Can someone please explain why -6 line can't be used? Mark | ||

Captain_america |

Mark you can use the -6 with no problem I assume like the Pegasus Race Team did, but if you look at everything the stock lines are the same size as the -8 hose. For some weird reason the threads in the fittings are -6 size (9/16-18). I wanted to keep the line size as close to the factory as possible to keep up the flow | ||

Polish_assassin |

Thanks Captain, Looking at your pics again I can see what you mean. Are the fittings and couplers that PP carries produced by aeroquip? | ||

Andros |

Jens, where do you order these fittings? | ||

Wi_dale |

Was a kit ever put together for this? I need new lines now (without a bike until they are replaced) and really like this option, but am mechanically inept and need a kit & instruction. Thoughts/suggestions? Thanks! | ||

Muli |

I replaced my stock ones with ones i made up on the weekend. Took maybe about a good hour or so making sure everything was right.  |