| Author | Message | ||

Dipstick |

What all needs to be safety wired on an 1125R for track day and how do you safety the right side oil drain plug? The head of that drain plug is very thin and dosen't leave much room for a 1/16 drill bit. | ||

Slaughter |

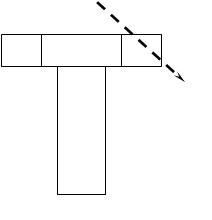

You should have a guide online published by the particular organization that you'll be riding with. They ALL have different safety wiring requirements. Check it out first with them before you do a ton of unnecessary work. Safety wiring doesn't HURT - it's just that if it's not REQUIRED to do, you can save yourself some effort. Some track day operators do not require ANY safetywiring. Some require wiring ONLY for advanced. Some require wiring EVERY hose clamp, EVERY hydraulic (brakes and clutch) fitting AND EVERY oil line/oil galley fitting including the oil filter fasteners - add to that the muffler hangers, brake caliper mounts... you'd do well to check it out first before doing ALL that MIGHT be required. On a bolt head, usually you can drill at an agle through the head of the bolt in the top and out the edge... (sketch) just barely enough to pickup a wire. Not HAVING an 1125 (not knowing how little metal is in the bolt head), I can't really help you there. I've done it on a few fittings on the XB - some places it's the only way you're going to be able to do it simply.  Check also if they'll allow use of JB Weld instead of safety wire on the oil fittings. Saves a TON of time - just a little booger to prevent unscrewing and it'll knock off with a screwdriver really easily. | ||

Fresnobuell |

Check also if they'll allow use of JB Weld instead of safety wire on the oil fittings. Saves a TON of time - just a little booger to prevent unscrewing and it'll knock off with a screwdriver really easily. Now that is what I am talking about. Love that idea. | ||

Dipstick |

Thanks Slaughter, I'll check with each track and see what they want. I did not realize they different standards. I just figured they all wanted oil plugs saftied. The right oil drain plug on an 1125 looks to have about a 0.10" thick head. I have a spare one on order and I'll drill it when it gets here. That way if I mess it up, I won't be stuck. | ||

Crusty |

You might try something like these: http://www.mcmaster.com/#catalog/115/3173/=1qwl0d Scroll down to Safety Wire Locking Retainers | ||

Slaughter |

WOW Crusty - those are GREAT - and will pass any tech inspection I'm aware of! (but NOT if the base of the oil drain plug is an O-ring seal) | ||

Bud |

i welded a bent ( 15deg)stainless washer on it, making sure i can still used the hex | ||

Dipstick |

Thanks Crusty, those tab retainers are a pretty neat idea. The right side oil drain plug on an 1125 has a thin round head. (Allen wrench) Bud's idea of welding a bent washer on it may be the best way to go. | ||

Dipstick |

Thanks Crusty, those tab retainers are a pretty neat idea. The right side oil drain plug on an 1125 has a thin round head. (Allen wrench) Bud's idea of welding a bent washer on it may be the best way to go. | ||

Mesafirebolt |

Most safety wire fasteners are drilled in a jig. If you dont have that, heres my recommendation (jet mechanic, I've done it for years) You drill through the side across from one flat to the other or all the way across the bolt head. Its easiest if you start with a much larger bit, well 2-3 times larger, to get a place to start the cross hole kinda hard to describe here. Try googling it... Anyway! the hole should be just larger that the .032 wire you are using, .041 for very large bolts, and maybe ever some .025 for the very small. As far as whats required to be saftied...anything that if it comes off will cause part of the bike to become unsafe or cause a spill on the track. |