| Author | Message | ||

Heavy18 |

2006 XB12X, K&N filter, aftermarket exhaust with updated fuel maps. Short version: Either heavy rain or standing water on the road that gets splashed up by my tire seems to be killing my engine. Long version: Coming home from a trip to Moab I hit some snow; it wasn't accumulating on the ground but melting and creating standing water. My bike cut to one cylinder and then died completely. The lights were on, no check engine light, starter cranked away. After sitting for 10 min (not a good time in a spring snowstorm on the side of a highway...) the bike starts to want to fire up. I finally get it sputtering again and it switches between firing on one cylinder and two and then died again. This happened two more times until I was able to summit the mountain and start down the backside where the storm was letting up some. The check engine light eventually came on then cleared out. As the roads got drier and my engine continued to run it ran more and more smoothly until it was mostly normal but running rich. I gassed up in Heber, then there is another summit and on the backside we hit driving rain and standing water on the road again and within 3 miles my bike died and would not start for 30-40 min. Luckily I was an hour from home and my wife brought the trailer to get me. This is the second time this has happened on a trip. Light rain will not cause it, it seems either it has to be heavy precipitation or it is the standing water on the road that causes it. Any ideas on where I can look for the problem? I plan to use a hose this weekend to try and recreate the issue in my driveway but wondering if anyone has had a similar issue? | ||

Hughlysses |

I suggest you start by checking the ignition coil and wires. The coil can crack, allowing moisture in and temporarily shorting it out. Similar thing with ignition wires. The front plug wire is susceptible to getting rubbed through by the idle screw cable. Even if they look okay, if the wires are original to the bike they are probably due for replacement. | ||

Smorris |

less likely but possible is water causing problem with pick up wire on right side where goes into "nose cone?" please post resolution. sometimes with cracked coil you can see stray sparking at coil in dark situation and bike running, no water required. | ||

Ratbuell |

Agree on the coil and wire suggestion. Also check the plug boots. I had a front cylinder issue on mine where the boot at the front plug was torn, allowing an arc to the head instead of to the plug. Temp fix was about a foot of electrical tape wrapped around it to insulate it, while I waited for new wires to arrive. Do your gauges drop out at the same time? If you're getting a system outage, check the connectors on your voltage regulator. It's right on the front of the engine and with a bad seal, a good splash could shut down the whole electrical system momentarily. | ||

Heavy18 |

Thanks for the tips, I'll check for arc tonight. While I have been suspecting something with the coil/wires, they were both replaced last year. The wires are from a 90's or 2000's era Corvette, but they were good thickness and the right length. After seeing first hand the wear on the front wire I wrapped them in titanium webbing to protect them. Nevertheless I'll be sure to remove them and thoroughly inspect even if I don't see signs of arcing. Gauges do not cut out, RPMs and speed still register when running on one cylinder and after engine dies (as I coast to a stop). High beam light stays on, blinker flashes, etc One more bit of info: after I got gas I turned on my ECMDroid and did a quick scan. There were two stored faults, both for the rear O2 sensor. One was something about no signal and another was about running lean if I remember right (I should have taken a screen shot). I don't know if those are old codes or new. I do have a new O2 sensor I've been planning to install as preventative maintenance but the back half of the engine seems mostly dry so I can't imagine that is being effected by rain... | ||

Ratbuell |

If you have a dead hole, you're going to be running rich. Injectors still fire even when the plugs don't. May want to do the sensor to be safe - and check its wires while you're in there anyway. Have you done the steering head ground fix yet? Usually that only cuts out the instruments, but you never know what could happen if wires start to arc/short/open at random. If it were me, I'd unwrap the titanium on the plug wires, and wrap it in plastic wire loom. Use an insulator, not a conductor  | ||

Mark_weiss |

Both times that I had wet riding misfires my front cylinder plug wire was the culprit. | ||

Tootal |

| ||

Heavy18 |

Update: I finally had a solid chunk of a weekend day to dig into this. I was able to recreate the issue by spraying water from my hose up between the frame and engine - simulating spray/splash from water on the road off my front tire. Once the area was saturated with water it would not immediately re-start. I removed the coil and wires, removed the titanium sleeves. There was some sort of corrosion around the front coil bolt hole and reddish dust or something around the front plug port on the coil. It appears to be evidence of arching? (see pic below). I know that the coil grounds through the mount so I cleaned the metal mounting area with steel wool as well as the bolt hole on the coil. I also applied some dielectric grease to the mounting/grounding points, wire boots, outside of the ignition wire ports, etc. I disassembled and reassembled several times, changing where and how much dielectric I added to the wires and mounting points. In the end I left it at 90%-ish good. I can still kill the engine when at idle after a few minutes of spraying water up through the frame from underneath (or straight down on the wires from above with the airbox off). If I hold the throttle at 2-3K RPMs it does not die. I decided this was good enough for now but I am hell-bent on a complete, 100% resolution. I did some research on dielectric grease and can see that I'm probably masking the real issue with copious amounts of the stuff. The only root cause I can determine is that the Corvette wires may not be making a tight enough seal around the coil ports? I went online and ordered a set of Buell specific wires from www.ironmachine.com. My plan is to disassemble again, clean off ALL the dielectric grease, install new spark plugs - coating only the ceramic part with a thin layer of dielectric. Reinstall the coil, with a thin layer of dielectric around the outside of the wire ports, then install the new Iron Machine plugs and retest with the hose. For what it's worth, I have two good ignition coils, I've tested with both of them and had the same results. I also ran a new ground wire from the negative battery terminal to the mounting bolts on the coil. Here is a pic of the reddish dust on the coil pack - both coil packs have been used on my bike and have this on the leading port... so it is either arching or there is some other issue around that area? (you can see where I had started to clean the dust off - I cleaned up the steel wool shavings I promise!)  | ||

Uly_dude |

I had this same issue while on a weekend trip. Not fun. I had previously installed some "high performance" spark plug wires from some place and didn't realize til too late, that the cuff at the coil end of the wire, did not make a perfect seal. Thus the rain got in there and I was only riding on one jug. Not cool. It took me 3 hours to disassemble/figure it out on the side of the road, but I got it. Replaced the plug wires with stock HD wires. No more rain issues! | ||

Tpehak |

The reason it did not start for 30-40 min is because of you ran it on one cylinder and the second cylinder just swallowed fuel without igniting it and fuel soaked the plug. When the plug is soaked in fuel id does not produce spark. It took some time (30-40 min) to evaporate the gasoline from the flooded plug and after this you were able to start the engine. I also would not recommend to run the engine on one cylinder because of after some time there can be so much fuel in the non working cylinder that it can hydro lock it and damage the engine. And this is why probably your engine stalled after some time working on one cylinder - the non working cylinder after some time was full of liquid (fuel) and generated a lot of resistance at some point. It might be stalled because of the not working cylinder was hydraulically locked. I had issues with running on one cylinder but that happened only on starting the cold engine on colder (comparing with recommended) plugs. So I run now only hotter recommended plugs. If you have running lean error you might have air leakage in the intake. When engine runs lean the ECM adds more fuel and at idle speed more fuel can flood the plugs and stall the engine or one cylinder (especially if your plugs are colder than recommended). The leakage in the intake can have inconsistent airflow (when the intake wobbles or the intake seals soaked it oil or fuel) which means there is a possibility when ECM adds more fuel when it detects more air due to bad intake leakage but the next moment the intake air leak can be less bad but the engine still dumps a lot of fuel to the cylinders and just floods the plugs and stalls the engine or one cylinder. Bad throttle position sensor or not calibrated properly TPS, or bad TPS wiring can stall the engine easily (If TPS is not calibrated or TPS or TPS wires are bad the ECM can think that the throttle position is wider than it is in reality and just dumps a lot of fuel when the actual throttle position is narrower and again it floods the engine plugs due to lack of air and excessive amount of fuel. Bad TPS or bad TPS circuit can cause O2 sensor error too. If the ECM receives signal from bad or not calibrated TPS and the signal indicates less throttle angle than it is in reality the ECM adds less fuel while the engine sucks a lot of air and the O2 sensor detects a lot of air (lean) accordingly and ECM sends the check engine light error with "O2 lean" error message. (Message edited by TPEHAK on June 22, 2023) | ||

Tpehak |

OK, you sprayed water on the engine and was able to stall it? Did you spray it on the intake area by chance and it changed RPM or staled? If so my bet is on the intake air leak | ||

Heavy18 |

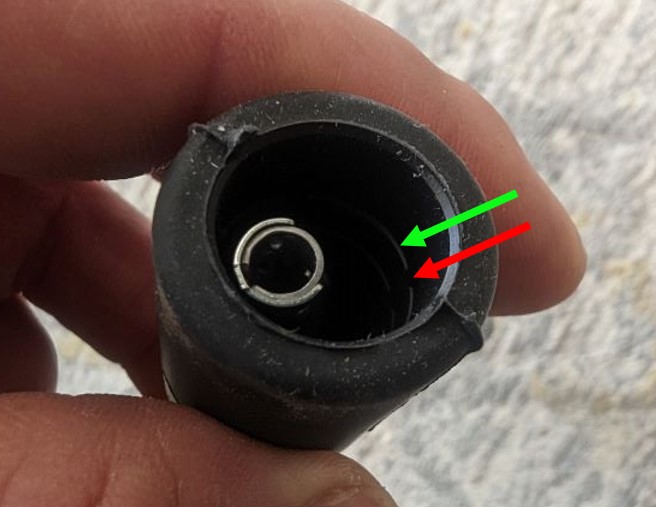

Uly_dude that is exactly what my problem turned out to be. Some 18 months ago when I first bought the Uly I was chasing what would turn out to be a bad ECM (broken solder joints) and while troubleshooting I found my front wire had worn through against the throttle cable. Not wanting to wait for a special order I found that 2000's era Corvette wires were about the right length. But they have two critical flaws: 1) there is a 45* angle at the coil. I believe this causes the boot to pull away from the coil when it is straightened out (as it will once installed).  2) The Corvette wire has very subtle "ribs" that are very deep down and they have breaks or voids in them allowing water to enter. In contrast the ironmachine wires I ordered had three very pronounced weather tight ribs starting at the boot edge with no breaks in them. This pic is the Corvette wire, the green arrow shows the rib, the red arrow shows the break in it:  Sorry, I didn't get any pics of the ironmachine wires but they were thicker diameter, tighter fitting around the coil and I believe the coil boot was just a tad longer as well. My driveway tests with the hose showed dramatic improvement with the ironmachine wires and at no point could I get the idle to change by spraying water nor could I ever get the engine to quit after installing them (and new plugs). Tephak, thanks for you insight, the intake boots are on my list of "to do" things just because I don't know how old they are and I know they go bad, but that does not appear to be an immediate issue for me. Also, I've never heard of a fuel injected engine hydrolocking on fuel? I was under the impression that on the exhaust stroke, the unspent fuel will mostly be evacuated out the valve and into the exhaust, which of course causes the sputtering and backfiring... But what you say about the plug being too wet does make sense. FWIW, I've seen a lot of pics and videos of your Buell and it is SHARP! |