| Author | Message | ||

Blitzer454 |

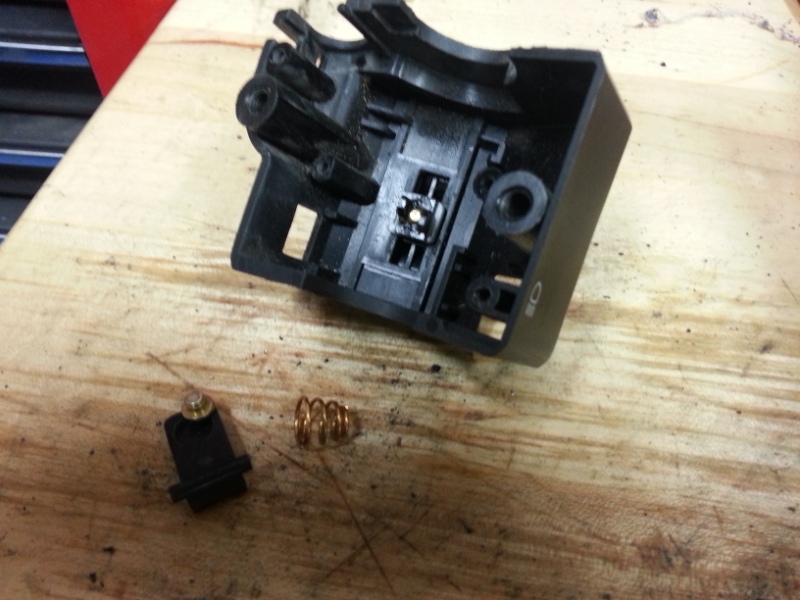

I broke my horn switch last summer and today I decided to fix it. This is what the original switch looks like inside the control. Current flows through the spring to a little contact slug that sits on the plastic horn switch lever. When you press the horn switch the spring compresses and the contact slug makes contact with the contact pad on the PCB.  And here are the disassembled parts  I replaced the broken plastic switch lever with a metal piece that I made from some scrap metal I had lying around.  Using a hand file I reduced the width of the metal so it was the same width as the plastic piece. The little tabs will become the pivot point.   I bent it about 90 degrees at the pivot point  I cut the metal to same length as the plastic piece. Then I started test fitting into the housing. I rounded off the pivot tabs with the file until there was no restriction when mounted back into the housing.  I then drilled a counter sunk hole to hold the metal slug.  Painted it black.  and reassembled  it works as good as the original, actually it works better because I know this one won't break. | ||

Ourdee |

I would have painted it red. Very good. | ||

Brother_in_buells |

Looks good! ,i did cut a piece of it on my 12s because thought it was sticking out way to long. | ||

Teeps |

Nice! There is great satisfaction in "smithing" a repair part. A part that will likely never fail... | ||

Motorbike |

Wow! Nice work. You have much more patience than I. |