| Author |

Message |

Reepicheep

| | Posted on Wednesday, April 30, 2014 - 10:44 am: |

|

Exactly. And the belt still has tension when it is done (though no doubt less tension).

There are a variety of reasons I did it, probably rooted in a transmission rebuild of my first Buell, and M2, that was probably needed due to bad information in the service manual (IMHO).

On the XB9SX when I did it, I don't think it did much beyond making tire changes a bit easier. 10k+ miles without enlarging them, 20k miles with them enlarged, still solid original belt when I sold it.

On the XB12X (Uly), it did make a significant change when I did it. Before I enlarged those bolts, I could feel the suspension bind up on big bumps with a heavy load. Afterwards I did not feel that happening.

So it probably didn't matter on the 9sx, and it may not be necessary on all XB12X's. But maybe some have tolerance stack up issues that make them just a little tight under particular circumstances, and in the case of a tight belt "a little tight" can lead to *extreme* bearing loading because of huge leverage (Blake did the math many years ago, and its insane how much of a load a belt can put on a bearing in a suspension binding scenario).

(Message edited by reepicheep on April 30, 2014) |

Glenn

| | Posted on Wednesday, April 30, 2014 - 11:20 am: |

|

Great and thanks for the detail. I think I'll be doing the same. I've noticed the binding too, noticed it last Sunday on a ride. |

Rbuck53

| | Posted on Wednesday, April 30, 2014 - 11:21 am: |

|

Now...I have to ask these questions since Buell was well aware of this problem when 2010 came around and a "fix" was needed: Why go through the excessive cost of redesigning and building a new rear wheel to accept a third bearing as opposed to simply revising the belt follower with a spring loading feature? After all, putting three bearings in the rear wheel hub did not solve the problem of the belt being too tight...right? The three bearings only shift more of the load to the belt and the trans...right? How is that a fix? Why would an "engineer" do this? Is there more here than meets the eye? Other than Free Spirits, has anyone else come up with a variable load belt tensioner for use on the XB? |

Trojan

| | Posted on Wednesday, April 30, 2014 - 12:18 pm: |

|

Other than Free Spirits, has anyone else come up with a variable load belt tensioner for use on the XB?

Other than blatant copies no.

Why did Buell not build one? Because they consistently denied that there was ever a problem (like they did with right side air scoops, which they said would cause probelms with fuel rail temperature, and 'slotted' airboxes until they made them standard on later models).

Manufacturers have reasons for doing/not doing things. Sometimes it is due to cost and other times it is simply because they don't want to admit that they may have got it wrong to begin with. Buell were not alone in this respect and there are plenty of examples of various manufacturers initially denying a problem then modifying an aftermarket solution in later models. |

Uly_man

| | Posted on Wednesday, April 30, 2014 - 01:49 pm: |

|

"Before I enlarged those bolts, I could feel the suspension bind up on big bumps with a heavy load. Afterwards I did not feel that happening". I do recall this on my 06 bike before using the FST. I ride over BIG speed humps at 30 odd mph and the bike just "glides" over them. One thing to remember is that the FST is taking out that "shock" load on the belt which would also effect bearings as well. It may also benefit the rear shock as well.

Thinking of all the good reasons to have one I would buy one again. I have no issues with the design or build quality or the price for that matter. Part of the "price" is Trojans great service. This is something that used to be taken for granted but is not so much the case these days. How many here have called to question a product/ service and ended up trying to talk to someone in outer Mongolia or other place. Yes you know were I am coming from dont you. I am NOT going to say Trojan is perfect and I do not think they would say so either but I have not had a problem and spent LOTS of money with them over the years. Thanks Matt. |

Rbuck53

| | Posted on Wednesday, April 30, 2014 - 04:20 pm: |

|

Is the pulley wheel the same size for the XB9 as it is for all the XB12's, as it is for all the 1125's? Are they all interchangeable? Same o.d.? |

Uly_dude

| | Posted on Wednesday, April 30, 2014 - 04:36 pm: |

|

besides the belts breaking prematurely, there is the rear wheel bearing failure that was even a bigger concern. thus the 3 bearing design I would guess Rbuck. There are some of us that believe the FST helps both the belt and the rear bearing issue. of course none of us know for sure but it's cheap insurance. |

Jesse_lackman

| | Posted on Wednesday, April 30, 2014 - 05:45 pm: |

|

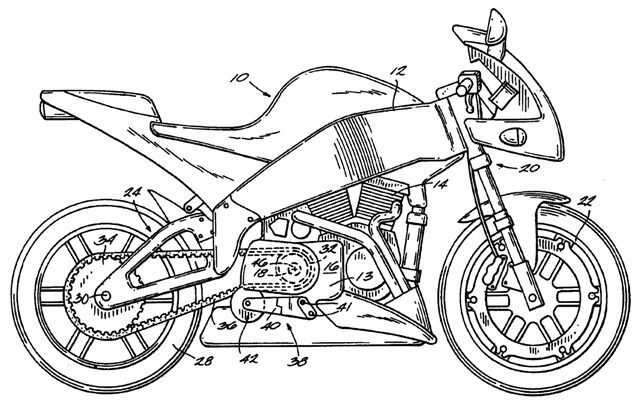

The original 2001 patent states; "the belt path length remains constant within approximately 0.008" as the swingarm pivots through its full range of 16 degrees."

And; "In the level condition the drive belt is in contact with the roller over a first arc length. When the rear wheel is moved into the raised condition the rear wheel is moved away from the output shaft, but less of the belt contacts the roller along a second smaller arc length. When the wheel moves into the lowered condition, the rear wheel is pivoted closer to the output shaft, but the resulting slack is taken up by the tensioner as the belt contacts a third larger arc length of the roller."

2001 was before the X was built. The belt path length for full extend/retract would not be that hard to check. If the belt path length variation is really is that small of an amount on the X it would explain why simply off setting the tensioner holes might work as well as a spring tensioner.

Reference; http://www.google.com/patents/US6866112 |

Jesse_lackman

| | Posted on Wednesday, April 30, 2014 - 05:54 pm: |

|

Reading the patent and understanding the engineering behind the system makes me feel a lot better about the design. I'm sure those belts have a tension spec. If the OEM tensioner is made adjustable then just set the belt to the correct tension spec and ride. |

Trojan

| | Posted on Thursday, May 01, 2014 - 05:20 am: |

|

The original 2001 patent states; "the belt path length remains constant within approximately 0.008" as the swingarm pivots through its full range of 16 degrees."

Just because the patent says so doesn't make it true unfortunately. There are millions of patents filed for devices that never worked.

The only way to have zero deviation in belt/chain tension is to mount the front pulley concentric with the swingarm pivot (or run a hardtail with no suspension!) like BMW did with the G450 trail bike a few years ago. As soon as you have the front pulley in front of the swingarm pivot then the tension will increase with load. However it isn't the load itself that snaps belts but sudden shock loads such as when riding over speed humps, railway crossings and other uneven surfaces that put sudden hard shocks through the belt. The FS tensioner absorbs these shocks and lessens the chances of belts snapping due to shock loading. As others have said they also give bearings a much eaasier time and reduce 'binding' even at walking speeds.

Thanks Matt.

No thank you  |

Reepicheep

| | Posted on Thursday, May 01, 2014 - 08:40 am: |

|

It is also possible the change to a 3 bearing rear wheel was just a reasonable change when they went to redesign the rear axle anyway...

The redesign may have been because the original design was sound when the installation and torque specifications were followed, and they decided that while they were in there they might as well change it to a 3 bearing design, maybe because the Uly now existed and had a lot more weight, and the 1125 (if it uses the same wheel) now existed and had a lot more power.

Who knows. Like Matt says, design criteria and reality don't always match, and there is unfortunately no testing as good as building a bunch of stuff and waiting for the phone to ring... |

Jesse_lackman

| | Posted on Thursday, May 01, 2014 - 10:47 am: |

|

From what I understand the drive pulley doesn't have to be concentric with the swing arm pivot; as the rear wheel moves up and down it also moves forward and back making the belt path longer and shorter. But that longer and shorter movement is canceled by more and less interaction with the fixed tensioner pulley. The design makes logical sense. It would be pretty sad for Buell to lie on a patent. I can't imagine that they would publish .008 belt path length variation without having actually measured it - or at least modeled it in 2D CAD - which would be pretty simple to do.

Rotational shock loads are completely separate from belt path variation loads. So is debris between the belt and pulleys. It would require a variable tensioner to handle them.

I'm curious enough about the belt path variation to measure it through suspension travel. |

Teeps

| | Posted on Thursday, May 01, 2014 - 11:34 am: |

|

Lets flip the discussion and ask the folks at Free Spirit to prove "their" math, with regard to the subject. |

Trojan

| | Posted on Thursday, May 01, 2014 - 02:12 pm: |

|

It would be pretty sad for Buell to lie on a patent.

Nobody said they lied, but patent applicatins are based on theoretical information as mch as anything else. real world long term use can trun out differently to what the patent was designed to do.

From what I understand the drive pulley doesn't have to be concentric with the swing arm pivot; as the rear wheel moves up and down it also moves forward and back making the belt path longer and shorter.

The rear wheel moves in a constant radius arc so cannot move backwards or forwards, just up and down. Unless the swingarm pivot and chain/belt sprocket are concentric you will always have a difference in tension when load is applied.

Sit on any bike you like adn watch the chain/belt tension under your static weight. Now imagine that happening over sharp bumps at speed. That is shock loading and I don't think the patent foresaw that.

Lets flip the discussion and ask the folks at Free Spirit to prove "their" math, with regard to the subject.

I don't think they have to 12 years of constant tensioner sales and lots of happy customers are proof enough really. |

Reepicheep

| | Posted on Thursday, May 01, 2014 - 03:20 pm: |

|

I think Free Spirits tensioners are junk designed by amateurs, because no one has ever won a WSBK race using one.

When they finally get serious about running a world championship team, and winning a race (because that is how we can tell if a company is good or not), then I'll consider buying their product.

Otherwise, nobody is taking them seriously, and they are embarrassing themselves selling a sportbike product when they can't even grid for a WSBK race.

Oh, sorry wrong thread. |

Uly_man

| | Posted on Thursday, May 01, 2014 - 03:53 pm: |

|

Sounds like a solid argument to me Reep. |

Rbuck53

| | Posted on Thursday, May 01, 2014 - 04:56 pm: |

|

Our rear axle travels in a fixed arc relative to the swing arm pivot, not in a fixed arc relative to the center point of the drive pulley. If the distance from the drive pulley center to the rear axle center point remained constant during the complete stroke of the suspension, there would be no need for a tensioner. In our case any offset or misalignment between the swing arm pivot and the drive pulley center is compensated for with a properly positioned tensioner in order to maintain acceptable belt tension.

The question is...is our belt tensioner in the proper position to do this?} |

Jesse_lackman

| | Posted on Thursday, May 01, 2014 - 10:45 pm: |

|

"The rear wheel moves in a constant radius arc so cannot move backwards or forwards, just up and down. Unless the swingarm pivot and chain/belt sprocket are concentric you will always have a difference in tension when load is applied. "

Yes the rear wheel moves in a constant radius but the pivot point is NOT the drive sprocket. The swing arm pivot point is much higher and back from the drive sprocket centerline.

That is why the belt would become longer and shorter - it is caused by the wheel moving forward and backward in relation to the drive sprocket. If that is all there was to the design the belt would become tighter and looser through suspension travel. But there is more, the fixed tensioner wheel. The fixed tensioner wheel, by design, counteracts the rear axle's forward and backward movement - thus the belt path length remains constant within .008" though suspension travel.

Look at the effect of the tensioner on the belt in figures 3 (neutral) figure 4 (compressed) and figure 5 (extended).

For those of you with a Freespirits tensioner this would be easy to check. Does the spring length compress/extend through the suspension travel? |

Trojan

| | Posted on Friday, May 02, 2014 - 05:06 am: |

|

I think Free Spirits tensioners are junk designed by amateurs, because no one has ever won a WSBK race using one.

When they finally get serious about running a world championship team, and winning a race (because that is how we can tell if a company is good or not), then I'll consider buying their product.

Otherwise, nobody is taking them seriously, and they are embarrassing themselves selling a sportbike product when they can't even grid for a WSBK race.

ha ha. Free Spirits are not a bike manufacturer with a huge sponsor, and maybe they have the intelligence to realise that they wouldn't be competitive in WSb so don't enter. Just like KTM and Triumph did

Actually though, Free Spirits did run teams in the Italian Supertwins series for a number of years, with Xb and 1125 bikes. They all used a modified version of the tensioner with a chain kit  |

Rbuck53

| | Posted on Friday, May 02, 2014 - 07:20 am: |

|

When mounted, the FST spring holds a firm, steady pressure on the pulley guide roller against the belt. I would think that the FST spring would extend slightly with the wheel traveling upward toward full suspension compression, and would compress slightly when the rear wheel is at or near it's fully extended position. Looking at my FST I can say that the movement designed into this follower is not extreme...but I guess it wouldn't need to be since the belt path length only changes .008" throughout the rear suspension travel. |

Jesse_lackman

| | Posted on Friday, May 02, 2014 - 10:01 am: |

|

I'll be measuring the belt path length. Now that I said it I'll have to do it. No guarantee when though! Someone else might beat me to it. Ha! |

Twotalltodd

| | Posted on Friday, May 02, 2014 - 03:29 pm: |

|

Does anyone know where to get them here in the US? |

Turf_moor

| | Posted on Saturday, May 03, 2014 - 05:55 am: |

|

Import them from Trojan's in England. He sends stacks of them over. |

Trojan

| | Posted on Saturday, May 03, 2014 - 04:48 pm: |

|

yup

You can order online here.

http://www.twinshack.co.uk/Buell-parts/buell-xb/XB -Driveline/XB-Free-Spirits-Belt-Tensioner

Price works out at around US$167 at current rates. Shipping to the USA is around GBP12-15 (US$2024) |

Arry

| | Posted on Saturday, May 03, 2014 - 07:18 pm: |

|

Price doesn't seem too bad, but the shipping seems a little high. |

Trojan

| | Posted on Tuesday, May 06, 2014 - 06:06 am: |

|

Price doesn't seem too bad, but the shipping seems a little high.

whoops, mussed the decimal point out

USD20 TO 24 max  |

|