| Author | Message | ||

Apeofthoth |

Hello everybody, I'd like to start by saying I've lurked around for several weeks now and tried to come up with a solution but can't find what I'm looking for; so here goes... About two months ago I purchased an 07 Uly, 18,000 miles, appeared to be in perfect condition. The dealership changed the oil (with what I don't know, but appears clean to the day). Ran great at test drive, so I took it home. After about three tanks of gas (get about 195 miles before the "idiot light" trips) the motor starts cutting out for s split second at highway speeds after about 15-20 minutes of riding (oil light flashes). Looked on here and found that it was likely the ecm. Sure enough, moved the ECM down, inserted the plugs all the way, and placed padded adhesive tape around all parts of the ECM that made contact with the bike to cut vibration, direct heat, and impact (did notice two hair line cracks where the plug meets the body of the ECM). This completely solved the problem, and have not had this happen again since. At two weeks and one tank of gas later I immediately notice a low end stutter. Others have described this on this and other forums, but this essentially feels like the bike is bucking, surging, and all together not running right. I thought maybe it was cold, or gas was bad, so I continued to ride. The buck occurs from about 2,500 - 3,500 rpm, and is most pronounced in 2nd and 3rd gear. It is eliminated immediately when the clutch is engaged, and when more than 1/2 throttle is applied. I'm not noticing any odd or off engine noise, and no pinging. No loss of power noticed. I attempted what others stated had done to correct this to no avail. TPS reset using ECMspy (warm), increased idle speed (was running a bit low, 900-1,000rpm) and reset AFV to 100%. The ECM adapted, throttle response is now better and idle speed and take off are improved, but low rpm stutter remains unchanged. I'm not mechanically skilled enough to do much more, and don't want to take it into a dealership just yet until I've heard some opinions from you all (I've deep respect for you all!) Also note, bike tends to start hard when cold, but starts fine for every start after the first (for a days ride). Fuel valve kicks in normally. I'm as of yet not competent enough to check the timing (no way to get the rivets out...), but the timing zeros on ECMspy at 285 so I'm assuming its ok... Sorry for the novel, but I wanted to be as thorough as possible. Thanks to anyone that can help! Namaste! | ||

Uly_man |

"Sure enough, moved the ECM down, inserted the plugs all the way, and placed padded adhesive tape around all parts of the ECM that made contact with the bike to cut vibration, direct heat, and impact (did notice two hair line cracks where the plug meets the body of the ECM). This completely solved the problem, and have not had this happen again since". Doing this just stops the seat pushing on the ECM plugs. The damage is to the ECM plug mounts on the PCB of the ECM and will still be there and WILL cause bad running. If this is the case you will need to either repair it or replace it. Also check that the battery/loom subframe mount face is clean of paint as it causes no end of problems for the ECM numbers on the 06 bikes. It could also be other things like the engine temp sensor, air temp sensor or even the O2 sensor. (Message edited by uly_man on August 28, 2013) | ||

Apeofthoth |

Will likely be trying to find a new ECM. Local dealers aren't willing to do a tps reset with a EBR ecm on my 07, so I'll be looking for a stock one... Any ideas on where to find one (anyone?). Performed a breather re-route, and cleaned the IAT/degunked the throttle and intake. Amazed at how much better it works/runs after just a little bit of cleaning. Haven't had a chance to take it out yet, but it definitely seems to be more responsive as far as the throttle is concerned, so at least something good came from this. Thanks for your insight! | ||

Etennuly |

I have worked on several Ulys who's throttle plate edges build up with carbon deposits. This does not allow a proper fit to the bore and will mess up an otherwise properly done TPS reset. Now that you have cleaned it out have you done the TPS reset again? | ||

Buewulf |

I agree with Ulyman and think that ECM is likely damaged. Check the grounds for good measure. | ||

Apeofthoth |

I have attempted a TPS reset or two since the last post, and I'm finding that ECMspy disconnects from my bike before the reset is complete; I've read on here that this is a common problem for some with ECMspy. Trying to get tunerpro working but I don't as of yet have a functional laptop I can run it on. I'm starting to think that a (apparently not so) simple TPS reset may be what's in order here. The problem still persists, but my new ECM should be arriving sometime next week. My project for next week is to get Tunerpro working and attempt a proper TPS reset. Thanks for your help everyone, I'll keep you all updated! | ||

Uly_man |

If you are trying to do this with EcmSpy it will be the same with TunerPro. Or in other words using a laptop and should not disconnect. TunerPro needs the prog/interface from TunerPro. Do you have it? | ||

Electraglider_1997 |

Apeofthoth, You may end up needing to talk to someone within your own profession.  | ||

Froggy |

I doubt that is the case, it disconnects once the reset is complete, the second you hit "reset TPS", it is done. You need to hit the keys icon to connect again to adjust the idle back into place. | ||

Uly_man |

(Message edited by uly_man on September 05, 2013) | ||

Apeofthoth |

Just to update everyone, I've replaced the ECM with no change in my symptoms (although I will say that I am feeling a little more power and consistency off the line). I have found a knocking noise coming from the primary, which I suspect to be the loose flywheel issue frequently noted. Gaskets and primary locking tool have been ordered, and I hope to tighten that up sometime this coming week. I'm not sure that a loose flywheel nut or loose primary chain would cause the symptoms I've described, though I am aware that it can cause some rough riding. Thoughts? My next step will be checking other areas for shorts or damaged parts. Seems the consensus is that my issue is likely electrical. I've cleaned the IAT, and want to check the O2 sensor and engine temp sensor. Any way to test these without having to remove/replace them (e.g. ECMspy, disconnecting wiring from ecm)? SX's = bucking and surging at cruising speed in 1st, 2nd, 3rd gear that smooth out above 3500rpm and in 4th and 5th gear. NOT engine chugging, No miss or pinging. Attempts: TPS/AFV reset = no change ECM replacement = No change IAT and Intake cleaned = no change | ||

Etennuly |

Have you checked the very basic stuff? Front plug wire for rub through or not on all of the way on either end of each. Pull the plugs to check for fouling. Fouling is a very common problem right from a dealership. Starting the bike and not running it to full operating temperature each time can kill the plugs. Many bikes had fouled plugs from new because customers wanted to hear the bike start up in the show rooms. My personal rule, if I start it three times cold I need to ride it ten miles or so to not only keep the plugs happy, but to drive moisture out of the metal body of the engine/transmission so the oils do not turn into the grey brown milkshake that can happen. If the plugs have EVER fouled change them. They will come back to run OK except at low speeds under load and at the very top end. Kind of like what you are experiencing. The front one works with a box wrench, that rear one is best done with a proper spark plug socket, a foot long wiggle flopping extension and a ratchet. Put a little anti-sieze on the threads using a piece of vacuum hose to start the rear one several turns before using the socket. Cross threading sucks. | ||

Whisperstealth |

>>>Put a little anti-sieze on the threads using a piece of vacuum hose to start the rear one several turns before using the socket. Cross threading sucks. A LITTLE bit of anti-sieze. Too much will gunk up the threads, and make cross threading easier. And Cross threading sucks really, really bad! Just cost me $900 worth of sucking bad by the time I added in the gas to tow the bike to the dealership. And the dealership did me right, were really kick ass. Dennys Harley in Springfield, MO btw. | ||

Apeofthoth |

Thanks for the plug advice guys! I have new irridium spark plugs, was going to change them with the primary while I had the bike apart. So, I will certainly check the plugs out also. Taking the primary off this afternoon once I've got my ducks in a row... Will update later this week when I get ahold of the torque wrench I'll be needing for the flywheel nut. Thanks again. | ||

Arry |

Apeofthoth, Have you adjusted the primary chain? This can be done without removing the primary cover or any disassembly. | ||

Kag |

Had a similar issue on a Harley I owned that ended up being plug wires. Just saying plugs and wires are cheap Although this thread did remind me I need to do the breather mod | ||

Apeofthoth |

@Arry: I've not inspected it, but I am suspecting that it's loose, and I'm almost positive the flywheel nut is loose. Got my torque wrench today (borrowed from my father who works in a shop that does a lot of machine work) so I'll be opening up the primary this week (I'll have it open anyway so I'll check the tension while I'm at it). Just ordered some plug wires today and hope to have them by the end of the week. which leads me to... @Kag: I'm starting to think more and more every day that your conclusion might be the accurate diagnosis. The bike now has just under 20,000 miles, which means it just about time to replace the plus/wires anyway. I'm going to replace them this weekend. I have high hopes that the plugs and wires will fix the problem, and further more that tightening the flywheel nut and primary chain tension will smooth the bike out even more! | ||

Tootal |

The primary chain must be loosened to remove the cover. It's not like a Harley as the plastic ramp is part of the outer cover not the inner. | ||

Claybobber |

When i replaced my stator, i didn't get the chain tension set properly. So you may want to check the primary chain first, as Arry suggested. It can make a real racket if too loose. On the other hand it can make finding neutral difficult if too tight. | ||

Sirvincentblack |

2006 Buell XB12X stock- just got done replacing my stator. The primary chain tension bolt threads are aluminum and are cut into the primary case. They very easy to strip. I just had to helicoil mine..twice (didn't run the helicoil from the inside out the 1st time)put it all back together and my bike ran great to Joplin, MO (45 miles)then halfway back home(nwa)engine light came on, 5 minutes later lost both tack and MPH then bike started starving of power lunging and stuttering then died. Now even with a fully charged battery the starter just clicks and fuel pump barely sounds off. Been dealing with all sorts of electrical issues and to date have changed ECM, CPS, spark plug wires, plugs (thought not as often as Etennuly suggests)cleaned the paint off the ground bolts and now replaced the stator. I'm super frustrated with the stealerships ability to find the issues too. I'm thinking it has to be a power drain somewhere. Anyone know a good way to diagnose a poor ground or short issue. Not trying to hijack your post here but some of your issues sound like mine...Any insight is appreciated. | ||

Etennuly |

Does your battery have any accessory wires attached? Are there just the battery leads on the bolts? If so, there is an issue with the battery bolts being too long, they can tighten just as they bottom out not allowing sufficient connection, maybe the first time out or two, it will run fine, next time no start like you describe. Grip the battery terminal wires with your fingers, force them to move. If you get any movement they are not tight enough, try a star washer on each. | ||

Tootal |

Also sounds like a relay has failed or is failing. Swap your relays around and see what happens. | ||

Sirvincentblack |

No accessories although during that ride i had a phone plugged into the handle bar power. Only battery leads on the posts. Didn't mention last time that this is a replacement battery (non harley) but i did have it load tested a few short weeks ago before deciding to replace stator. it has screws into nuts system and not drilled out holes so terminals are tight. The neg wire was loose when i hit joplin. (bike wouldn't turn over or bump start) tightened and it powered right up and I started home. When it died the terminals were still tight. Tootal- what will happen if I swap relays? Something else will not work but bike will run? How do I use that to diagnose? | ||

Etennuly |

The relays are interchangeable so if you move them around you may be able to isolate a bad one. On the other hand, sometimes the pins on the relays can loose contact and moving them around can help that situation. The battery terminal thing is the same with aftermarket batteries, with the nuts in the cage. Your description of how it quit fits this problem. It is good that you had it load tested. My battery has lost this important bit of contact at least five times over the years since new. If ever these symptoms occur I pop the seat off to see if I can make the terminals move with as much finger force that I can generate. If they move at all I loosen them, clean them, and crank them down until I cannot move them. I had hoped this is your problem.....easiest and cheapest is best!  | ||

Apeofthoth |

So, I ended up taking mine to a local guy that used to be a buell tech. He said he'd seen four bikes the week before with my issue, and had two bikes apart in the shop with the same (harleys). @Sirvincentblack: he showed me several washers and bearings that lie between the flywheel nut, and the housing that covers the stator. he said that when the flywheel nut becomes loose, as mine had, it will cause these bearing(s) to grind. when they become ground down (even just the slightest bit) they fail to catch and spin, which fails to activate the stator properly between 2500 and 3500 rpms (depending how far ground they are 3500rpm is often sufficient to start charging). Anyway, moral of the story, if these little washers in front of the magnet are damaged they will fail to charge at low rpm (resulting in my 2500-3500 stumbles when letting off throttle/cruise but plenty of power while on throttle), and if seriously damaged the stator will not charge at all; which sounds like what youre experiencing. I cant find the part number for that little spacer/washer/bearing/little metal disk he was showing me. but it all starts with the loose flywheel nut or hard shifting... | ||

Reepicheep |

Hmm ape... he sounds really knowledgeable, but I can't quite follow that hypothesis. (I'm stating the following from memory for a couple of other Buells I have had apart, but I might be confusing it with the billion or so UJM's I've had apart... so people should feel free to correct me where I have it wrong)... The stator bell with permanent magnets attached just bolts to the crank. It is "spaced" above the stator by a shoulder that is machined into the crank itself. There is an aluminum cylinder behind it, which floats on the crank. It rides inside the crank seal. There is a crank bearing behind that seal, but to replace that I think you have to split the cases. I think there is a washer in there somewhere, but I can't remember where. Regardless though, while I could see a loose stator bell causing a charging problem (though probably by shredding your stator and stator bell), I don't get the "worn bearing" aspect of it. Oh well.... not the first thing that's real that I don't understand.  | ||

Apeofthoth |

I think he explained it as well as he could to someone like myself... it was just his hypothesis. just got a call from him moments ago, turns out its actually the clutch thats messed up. Sooo im on my way over to have a look. Thanks again every one! | ||

Firemanjim |

Can't happen, stator either works or not , there is nothing to "fail to catch". | ||

Claybobber |

Could be the clutch hub bearings found their way into the stator bell? Chomp Chomp!!! | ||

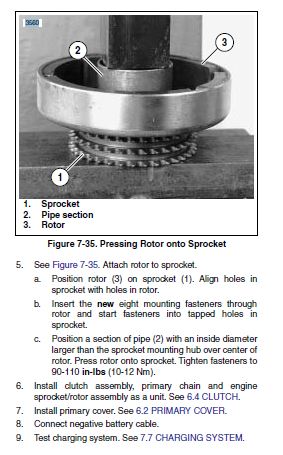

Sirvincentblack |

The nut holding the rotor assembly is torqued to 150fp and held with red threadloc .. . There isn't a washer but maybe what this xBuell mec is talking about is the attached rotor assembly? I changed the stator but didn't break this assembly down to its basic components nor do i think i could have checked for minor washer wear. (Don't even see a bearing or washer in this manual photo) My battery is holding 12.9 volts (off the bike) after fully charging it. | ||

Sirvincentblack |

My battery is holding a charge but is only getting 12.20 volts at 3500rpm. Stator@ 3500 putting off 44 volts. Stator at 2k rpm 32-40 volts. Regulator@ 3500 30-36 volts. So the battery slowly discharges causing ruining issues. | ||

Arcticktm |

If my memory serves at all from when I changed primary gearing (several years ago, mind you), I recall that they torque spec was actually revised even higher than the 150 ft-lb mentioned above. still with red loc-tite. All I know is mine has stayed together so far, and I hope this continues. | ||

Shagg1970 |

Yes the new spec is 250 ft-lb. I had to borrow a huge torque wrench from a friend who is a mechanic, none of mine went that high. |