| Author | Message | ||

Steveford |

This is not in any of the manuals but this is what you do. Timing is critical on these as the ignition timing controls the timing of both the spark and the fuel delivery. It must be spot-on for your bike to run as designed. The first thing to do is to check it as there's no sense in screwing around if you don't have to. Hook up the bike to the Digital Tech or ECMSpy and run it until the engine temperature reads 320 degrees F (160 degrees C). The timing advance should go to ZERO precisely at 320 - if it hits zero before or after 320 you need to adjust your timing. Raise the rear wheel off of the ground with a stand, remove the left hand scoop, remove the seat, remove both spark plugs, put the bike in 5th gear, drill out the rivets on the timer cover, remove the timing plate cover, remove the timing plug (see your shop manual for illustrations). Turn the key on and slowly rotate the rear wheel forwards until you hear the fuel pump kick on. Sit next to the bike, shine a flashlight into the timing inspection hole, use your foot to rotate the rear wheel backwards and then slowly tap the rear wheel forwards until you hear the pump kick on. If the pump doesn't kick on when the timing mark is straight up and down (180 degrees), rotate the motor until the timing mark is straight up and down, loosen the plate and rotate it a little bit until the pump cycles. Tighten the screws, rotate the rear wheel backwards with your foot a little bit, shine your flashlight into the timing inspection hole and use your foot to rotate the motor forwards. Do this until the pump cycles when the mark is straight up and down. Once you've got that, tighten the timing screws up (15-30 inch pounds), put the timing inspection plug back in, put the spark plugs back in, put it in neutral, hook the datalink up to the Digital Tech or your laptop and start the bike up. The two windows that you want to watch are the Engine Temperature and the Timing Advance. As the motor inches closer to 320 you'll see the advance drop down, down, down come on, you can do it, a little more, 318, 319 320 ZERO! You've got it. Good time to set the idle, too. Pop the timer cover on with new rivets, put the scoop on, put the seat on, put the rear wheel back on the ground and go for a ride. | ||

Alex |

Sorry to say so but I do have some doubt. The spark advance reading of the Dig Tech is just the number the ECU commands - not the number that the spark really occurs as the ECU has no information about the actual position of the crankshaft (as it has no crank position sensor). That´s why static timing is so important. So moving the cam position sensor will have no effect on the advance reading of the Dig Tech. Most important is that static timing is performed with the engine at front cylinder compression. If accidentially front cylinder overlap is used this will lead to some degrees misalignment. Regards - Alex | ||

Danair |

I gotta go with Steve on this one. You're giving the ecm a zero. ecm says spark x number of degrees before that based on its calculations using the data from all these%"#!#&/ sensors, and by the way, do it at the speed of light. I experimented with this after his 1st post. He is correct......and formally trained! After staring at ecmspy for hours and thinking "no wonder it runs like crap, it's got no advance" It actually starts at 27* btdc cold and does what he says....*at ldle* If you touch the throttle it will throw in advance but will return to 0 at idle at that temp or above. | ||

Reepicheep |

Great write up and useful information! The one thing that confuses me is the same thing Alex mentioned... Your process for adjusting the static timing makes perfect sense, and I have used that process several times successfully. But that's pure mechanical... so I don't see what you gain from getting it up to temperature and looking at the ECMSpy advance. Doesn't the ECM know the Crank Position from the Crank Position Sensor, which is what you have to properly zero? Wherever it is (wrong or right), that is where the ECM will think TDC is. So until you look at the mark on the crank and listen for the fuel pump cycle to tell you the hall effect sensor just turned on, you have no idea if it is timed right or not. And if that is the case, engine temperature doesn't seem important for just what is basically a mechanical alignment of two mechanical pieces (the CPS and the crank mark through the window). My guess is that your ECM checks for advance and temperature are preventing or discovering some other problem... Maybe it's necessary so the ECM turns on the fuel pump at the right moment (rather than advancing it)? If that's the case, it seems easier to just put a meter on the CPS lead and look for the voltage transition rather than try and dismantle a hot motor (or get a dismantled warm motor hot again). So I'm confused. (As usual.  ) ) | ||

Steveford |

I am simply relaying what they said at Buell XB school, I didn't think to question my instructor - he helped design the thing! I can say that by following his instructions the bikes don't run funny and there are no pinging issues. I often thought of this when reading all of the threads about pinging but nobody asked me what to do. I've received a lot of help here so figured it was time to return the favor. YMMV, as they say. I think that the deal with the temperature is that you're ensuring that the static timing is perfect. It's easy to get close but that's not quite good enough with this design and this is the way that you check the auto advance on these models. There is no rev it up to 4 grand and use a strobe, you use the computer and watch the temperature and the degrees. (Message edited by SteveFord on August 16, 2013) (Message edited by SteveFord on August 16, 2013) | ||

Reepicheep |

I wonder if the CPS gets more or less sensitive with temperature? That could explain some of it. | ||

Danair |

I don't know squat about the DDFI-3 but I read it has an idle air control valve. Which probably does what its named. Maybe this is DDFI 2 way of having a decent idle hot or cold...a compromise, since I don't think it has much else in the way of controlling idle speed. If there is I'd like to know because mine idle about 850/900 till warm then then 1050 | ||

Sagehawk |

Curious, i took some suggestions from xoptix on timing. i installed some values in the bottom 8 boxes of ignition timing charts (bottom left) which replaced zeros. To follow this temp procedure, do i need to return front cylinder timing values in those boxes to zero? That way, at the proper temp, then a true zero is to be found for timing value? | ||

Alex |

Ok guys, I would suggest the following: Danair - who seems to have a perfectly adjusted timing as it reads exactly 0 - should move the cam position sensor for about 3 degrees and recheck (after having backed up the engine temperature). According to Steveford it should then read 3 instead of 0. I claim that it will read 0 again as there is no chance for the ECU to recognize that the CPS was shifted. Go for it and tell me what You find. | ||

Alex |

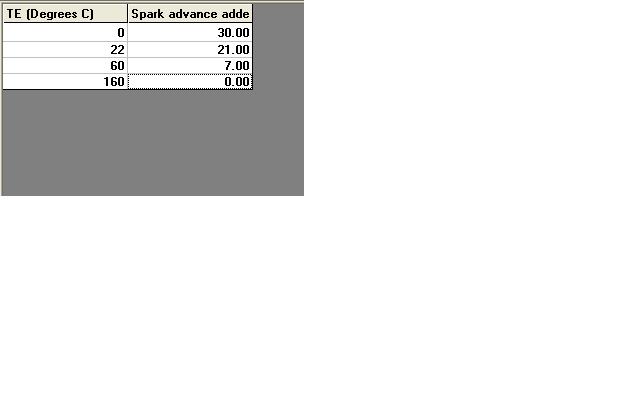

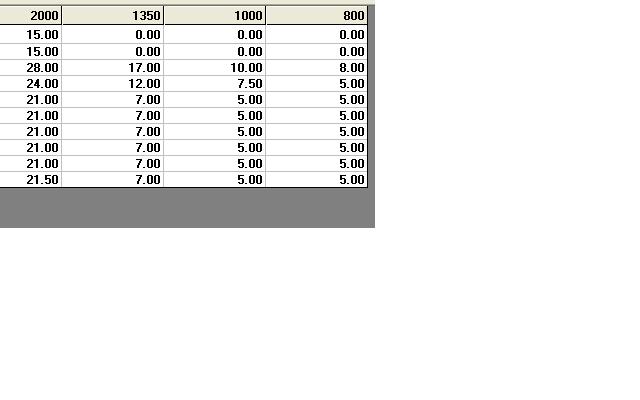

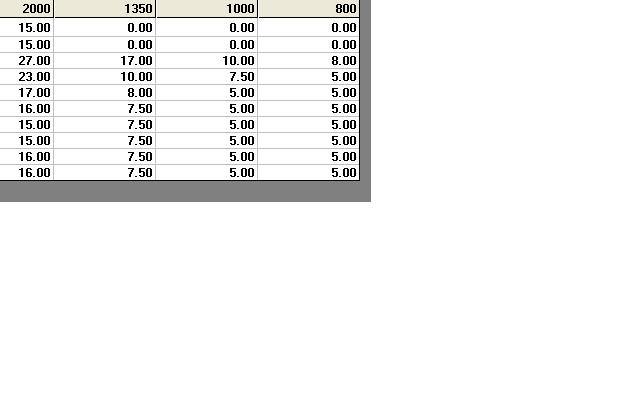

For further explanation: this is a typical correction table for idle spark advance based on engine temperature of a DDFI-2 ECU  Here´s the spark advance table (part of it) for the front cylinder  and for the rear cylinder  As You can see idle spark advance in the main spark tables is 0 which is corrected by the value from the first table according to temperature. So commanded spark advance at 160deg Celsius is 0 from the main tables plus 0 from the correction table. At lower temperatures correction will be higher. This is what You see on the DigTech. But what does it mean? It means that spark should occur at the calculated value with respect to TDC. But how does the ECU know where TDC is? It doesn´t really. All it knows is the signal from the cam position sensor CPS (read: from the windows in the "ignition" rotor cup). You set the CPS so that the trailing edge of the respective window in the rotor cup opens contact with the TDC mark on the flywheel beeing centered in the timing hole. The ECU knows the widths of the window (let´s assume the widths corresponds to 50° of crank shaft rotation). Now if the engine is in idle we get 0° advance from the main tables and e.g. at 60deg Celsius an additional 7° spark correction. The result would be 7° summed up (which You will see at DigTech). The ECU will now calculate that it will have to fire the spark 50° - 7° = 43° after sensing the leading edge of the respective window in the rotor cup which corresponds to 7° before TDC. What is going to happen if You move the CPS sensor? Will it have any influence on the commanded spark values from the ECU? No. The ECU still calculates 0° from the main table and 7° correction based on engine temperature (again You will read 7° on DigTech). It will fire again at 43° after sensing the leading edge of the rotor cup window. Difference is: the window is no longer "aligned" with TDC as You moved the CPS. Will the ECU know that You moved CPS? No way. So You will still read 7° advance on DigTech while real advance is a different number based on how much You moved CPS. Based on all this info and on everything I know from the ECUs I still claim that DigTech will read 0° at 160deg Celsius no matter where the CPS is positioned. If You wanted to have a "real" spark advance indication You would need a Crank Position Sensor. There is none on early XBs. | ||

Danair |

Hmmmm. Isn't the cam position sensor basically telling the ecm the crank position? Same exact data picked up from a different point? Does a modern full digital authority ignition system need to be "set" or adjusted? Maybe I'm dumbing it down but it seems this system is a mix of old school and whiz bang where the latest is all whiz bang. Just like the tps where we have to give a "0" and the entire operating spectrum is based on that. We all know what having that one a tad off results in, and not just at idle. Anywho, it runs fine but I noticed this...I received a bike and it was the best running Uly that I have ridden in terms of quickness...acceleration and just straight roll on power. Other Uly owners that have ridden it ask "you sure its stock"? Timing check way back showed it advanced, but just looking at the manual illustration of advanced and retarded, I assumed those to be the limits so I left as is. Changed it to perfectly centered and it definitely took an edge off of it. Runs fine but no where near as "snappy". It never pinged or exhibited any bad behavior, so I might just put it back. I love instrumentation, data and analysis and such but sometimes seat of the pants tuning just works...within limits. Glad I could start another "oil thread"  | ||

Steveford |

Set your timing however you like, it's not worth getting all worked up over. I did find the old link with my instructor, Gary Valine. He was just great to hang out with in that godawful smoking room they have up there. Does anyone know if Gary is still kicking? http://www.badweatherbikers.com/buell/messages/496 363/87441.html | ||

Reepicheep |

Exactly, and it's the only thing telling the crank position. So wherever that plate is set, *that* is zero degrees, regardless of if it is right or wrong. The temperature point is interesting though. I never quite trusted hall effect sensors in terms of precision, seems like they would be fussy instead of precise. But they are used in all sorts of applications like that. Seems like an opto-interrupter would make more sense. | ||

Sagehawk |

Mc advantages used to have a ignition system that was optically triggered. Their claim was hall effect sensors varied their precision by over 7 degrees for whatever reason. Only people that claimed that degree of inaccuracy that I've ever heard. | ||

Reepicheep |

Looks like many hall effect sensors already have built in thermal compensation. | ||

Danair |

"Danair - who seems to have a perfectly adjusted timing as it reads exactly 0" Setting up a little experiment before I button up. Regarding the above quote, when ecmspy said temp turned 160, still showed advance of .2 ...then .1 ... then zero right before it turned 161. For the bored or curious only..... | ||

Steveford |

I don't know if there are any ex factory employees or techs who are on this site any longer but if there are, I managed to dig up some info on Gary Valine and I'm happy to say he's still kicking and evidently doing just fine. Quite the resume: Experience Harley-Davidson Technical Training-Program Development Harley-Davidson January 2002 – Present (11 years 8 months)|Milwaukee, WI Responsible for training/updating Harley-Davidson dealership technicians in North America and developing training materials for our global network of instructors. Technical Instructor/Curriculum Developer Harley-Davidson Motor Company 2002 – Present (11 years) Engine Testing & Development Buell Motorcycle Company May 1994 – January 2002 (7 years 9 months)|East Troy, WI Engine testing and development Arrow Racing Engines General Manager Arrow Racing Engines October 1989 – May 1994 (4 years 8 months)|Rochester Hills, MI Engine testing and development primarily for various engine platforms at Chrysler as well as developing performance parts and packages for Mopar Performance. If anybody sees him, tell him the Buell guy with the pipe says hello. | ||

Rdkingryder |

Steve, is there any advice you can give me? I installed an '08 crank in my '07 and didn't realize there isn't a timing mark on my crank for static timing. I did thee best I could by adjusting the timing to the location where the screws left imprints on the plate. I tried a little Kentucky timing with it as well and didn't notice much difference, so I just left it where I initially had it. | ||

Steveford |

From flipping through my training book and notes it looks like that static timing mark is 3 degrees BTDC front cylinder. Could someone please verify that? Maybe the place where you bought it from could contact HarLee and see if this is correct? They must still offer some sort of Buell Tech Support. I just saw one of my notes: XB9 zero degrees at idle. You want to have the dealership contact HD Tech Support. It's been almost 10 years since I looked at this stuff. (Message edited by SteveFord on August 21, 2013) (Message edited by SteveFord on August 21, 2013) | ||

Alex |

Coming back to the "timing with temperature" method: we checked if that method would work as from my understanding it does not. We warmed up the bike and at 160° ignition timing jumped to zero (explanation: see above - result from the timing tables). After that we moved the cam position sensor for about 4 degrees (which corresponds to about 8 degrees crankshaft). Again we warmed up the bike and at 160° it right jumped to zero. Just as expected. Now if someone else wants to do the test please let me know what You find. |