| Author | Message | ||

Uly_man |

An easy repair but you would have thought that it would have been fixed with the last bikes? Thanks for the info guys. The beers are on me, LOL. | ||

Xbimmer |

Here's how I fixed mine, no more flexing at the terminal shanks and no more breaks, keep a spare in the tool bag.  | ||

Electraglider_1997 |

nice. | ||

Buelldualsport |

Great Solution Thanks for the input and update. Added to our MUST DO List Regards | ||

Uly_man |

Looks great. Mine went 20mm from the splice joint. I see that there are also OTHER splice joints in the loom as well? I think I had one going on the 06 bike as well. Two-for-two. Not good. | ||

Buewulf |

Funny how some things on this bike are so well thought out while others seem like they were designed and built from an 8-year-old's erector set. Nice job Xbimmer. | ||

Uly_man |

"Funny how some things on this bike are so well thought out while others seem like they were designed and built from an 8-year-old's erector set." I have had the same thought myself manyyyyyyyyyyyyy a time. | ||

Natexlh1000 |

I just gave up trying to find the break in the harness and ran a big dumb wire from the frame to the instrument housing. I didn't even use black  | ||

Cmgaviao |

So, as I'm trying to sort out the intermittent dying/backfiring still going on on my bike, I wonder if this might be the culprit. Any idea where the 4 cables that ground here come out at so I can check continuity? | ||

Rays |

I think I have had all four of these break at various times on my '06 and they are: - Headlight ground. - Blinker Relay Ground. - Horn Ground. - Front Aux Power outlet ground. | ||

Reepicheep |

Can you force the bike to trigger the symptom? I (unluckily for me, luckily for you) had two problems, either could both be causing your symptom. First, I had a broken wire in the neck around the steering head. This was self inflicted, as I stuffed a big horn under the flyscreen carelessly, and kept that harness bundle from being able to float freely when you turn the bars lock to lock. The result was my kill switch would open up at full right steering lock, and kill the motor. Took the flyscreen off and made the room again that it should have had all along, traced the wires by feel looking for kinks and weak spots (the internal break was very obvious) and fixed it and put it back together. No problem. I took the time to understand which wires go where, but that wasn't really necessary. The broken wire was obvious by feel. Next, I had a crank position sensor go out. That also caused the stalling and backfiring. On mine, it started as a hiccup every now and then (maybe 50 miles) then progressed to a hiccup very frequently (another 20 miles) to almost unridable (10 miles) to pretty much dead. The stalls would be followed by some pretty impressive backfires. That is fixed, but I'm not having issues with my exhaust servo, which I'm wondering if are the result of the backfires (there were a lot of of them). | ||

Cmgaviao |

Hey Reep, I can't force the bike to trigger the symptoms. I've cleaned and filed the areas around the 3 grounds. I've tried wiggling the wires back and forth around all the grounds. I've tried wiggling the connectors at the ECM. I've put playdough on the ECM to see if I'm hitting it when I'm on the seat and it doesn't seem to be the case. We reset the timing which was a little off but not much, and while doing so never noticed the CPS failing in that procedure. I am starting to lean towards the ECM though. This weekend after resetting the timing and going for a test ride, it took it a few miles to hiccup... (It generally seems to happen under load and moving..I've never seen it do it idling and me not on the bike). I promptly pulled over, pulled the seat, fiddled with the connectors on the ECM and the ground to see if I could get it to repeat, but no joy....I DID ride it all the way back putting almost no weight on the seat, standing on the pegs or barely sitting at the back of the seat and it didn't repeat at all. I kind of wanted an EBR ECM anyways...hopefully that will sort it out.... GF is actually giving me shit about working on it and putting time and money into it and trying to get me to get a new bike...I must be the only guy I know who's SO is actually pushing to get a NEW bike... | ||

Teeps |

Uly_man Posted on Tuesday, August 14, 2012 "Funny how some things on this bike are so well thought out while others seem like they were designed and built from an 8-year-old's erector set." It's what happens when 12lbs of ($#!t) is put in a 10lb bag. | ||

Reepicheep |

Cmg, my grounds were fine, it was internal breaks in the wire in the wire bundle that went down around the steering neck. Take the flyscreen off, take off any tape, and any other armor / covers on the bundle all the way to where it goes under the frame. Then pull each individual wire through your fingers flexing it slightly as you pull it though. It will be smooth flex for a good wire, but if there is a break in the copper (but not the insulation) you will easily feel it as it passes through your fingers. The insulation will be stretchy at that point as well (unbroken copper doesn't stretch like that). | ||

Djohnk |

Xbimmer, where did you get that curly wire gizmo with the white plastic on one end and the copper piece on the other for your ground? Is it home made? I just fixed a ground in that area last night. I would like to copy yours because I hate repairing my bike on the road. Reepicheep, last time I had my timing cover off I noticed my crank position sensor was really gummy ... when I touched the black insulation part it was kind of like touching softened tar. Is that what your bad one looked like when you replaced it? Anyone else chime in, I am wondering if I should replace it proactively. | ||

Reepicheep |

Yes, that's what they look like, good or bad. It's a stupid expensive part ($100+), so I'd confirm its dead before buying a new one). I bought a new one to fix my problem... then bought Hugh's old one off his retired parts motor to keep in my "jump kit" when I saw it go up for sale. It is a "hot spare" that I will bring in my jump kit. I'll probably not need it, but I'll feel better having it along. I assume it works (Hugh's motor died of other causes), but haven't tested it. I'd be willing to send it to you if you promise to send it (or some other working spare) back, but it might be easier for you to just find somebody with a scope and watch yours. It's a cool looking process.  | ||

Reepicheep |

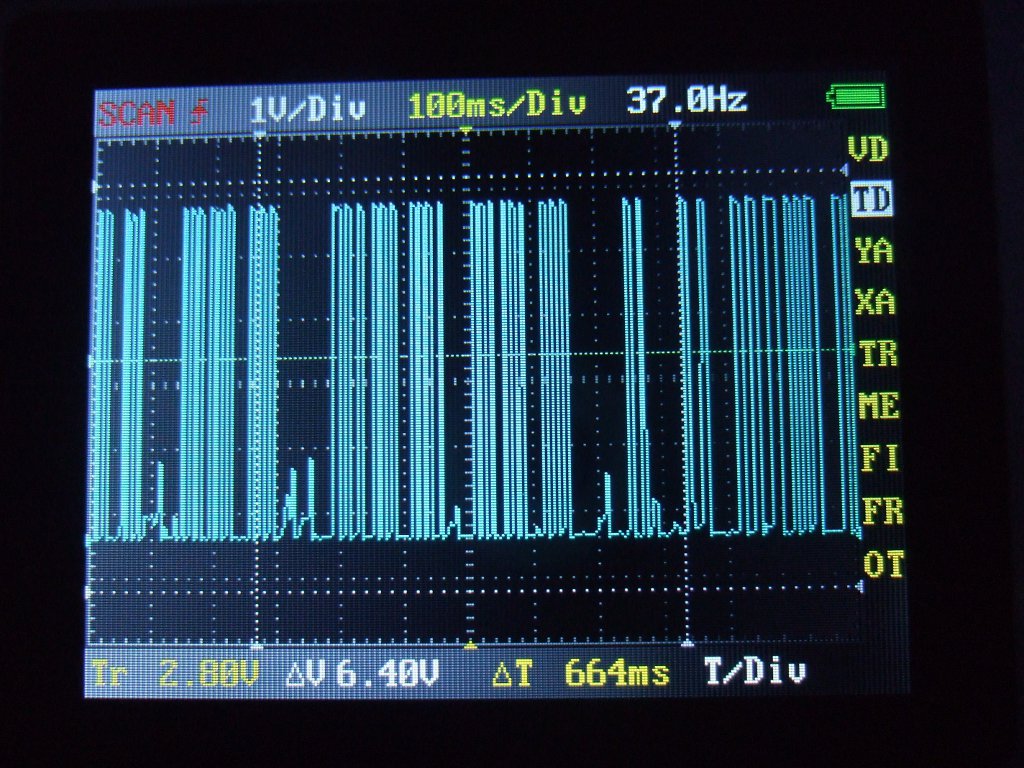

You can see above where my Cam Position Sensor was failing to Sense the Position of the Cam (err.... crank) in those holes in the waveform. My assumption is that the ECM would then not fire the spark, or would get confused about the RPM, and the net effect was intermittent power loss with the tach jumping around dramatically followed by bad backfires. | ||

Djohnk |

Thanks for the information and offer Reepi, I think I will go with your suggestion and look for a scope. It looks easy enough to set it up, you have the parameters in the photo above. I wonder if any of the logs on tunerpro could diagnose the CPS? | ||

Reepicheep |

The logs probably won't help you. They sample through the ECM, and the 9600 baud bit rate, and there are at least 8 bits in every sample. Even if there was no overhead (there is) and the CPS was the only thing you sample (it's not) you could only get 1,200 samples per second. Idle is already over 1000 RPM, so you would be getting just one CPS sample value every rotation... and you need many samples just to see when the CPS is on and off. The ECM could do more, and look for things like "instantaneous RPM changes" that could suggest a bad CPS... but there would be a lot of guesswork involved and it could be computationally expensive for an ECM embedded CPU that is already busy. The picture above is the DSO Nano V2 digital storage scope. At under $100, it's a nice tool to have even if you only use it two or three times, as it tells you things you can't easily know otherwise. When trying to decide if you need to replace a $150 CPS, a $100 tool isn't insane, especially if there is a good chance you could use that tool elsewhere. There was a DSO Nano V1 that is cheaper, and actually looks like it has a nicer case, but I haven't handled one. I also changed the "factory" firmware on my scope to use the "BenF" version, which I like better. It was a little cryptic to work out how to do the upgrade, but I figured it out. And the original firmware worked fine as well, particularly for this test. The other major limitations of the DSO scope are it's low maximum sample rate (1MHz I think) and it's inability to deal with high voltages out of the box (anything above 70 volts or so). The case for the Nano is a bit on the flimsy looking side, and the first one I bought had a bad USB port. It was replaced free of charge though, and I've used it a dozen times now, and it's holding up fine. It's just not up to my "Fluke 77" durability standards (though frankly, few things in life short of an anvil are). I've also seen some IPad scope hardware, that look cool as heck, but it's in the $300 range. I chose the DSO for it's low price and the fact that it is completely self contained. If your problem was more reproducible, you could just find somebody with a scope and have them take a quick look at it. But yours is intermittant. The CPS signal goes right up to the ECM, and a wire with a bare end will slip right into the silicone on the connector, which you could then run to the scope and tape the whole mess to the bike safely and go for a ride... either with the scope running or the probe disconnected from the scope and the scope in your pocket. Then pull over when it's behaving badly and look at the signal. Even if its not the CPS, the scope will help you in your gremlin hunt. Just work your way through the ECM sensor inputs and think about what they should be doing, and look at the signal. I had a lot of fun just playing with it (i.e. watching my O2 sensor output). | ||

Reepicheep |

(Here is the other thread on the topic, BTW) http://badweatherbikers.com/buell/messages/3842/68 6969.html?1343048488 I am top ranked on google for "Buell CPS waveform" now.  | ||

Djohnk |

Thanks for the info. I am a serious tool guy, when something breaks and I need a special tool I usually buy it rather than paying someone to fix it (the way I look at it is I get it fixed and get a free tool). I prob will get one of those, like you said they are pretty cheap and look very useful. | ||

99savage |

Funny this should come up. Horn quit working this PM. - Yup bad ground - Wire completely broken. Is there any reason not just tape that wire in place & ground the horn to the bracket it is mounted on? While we are under the cowl; The plastic connector gizmo to the lights rots. - If it moves 0.03" one or more lights quit working - Terrifying upon occasion. Tried every trick I can think of with little effect. sometime have to pull into a 7-11, remove the cowl & jiggle things. Anybody else had that problem & if so what did you do? Xbimmer That looks terrific What is it?? - I want one too. Details, give us details - Lots & lots of details |