| Author | Message | ||

Motorbike |

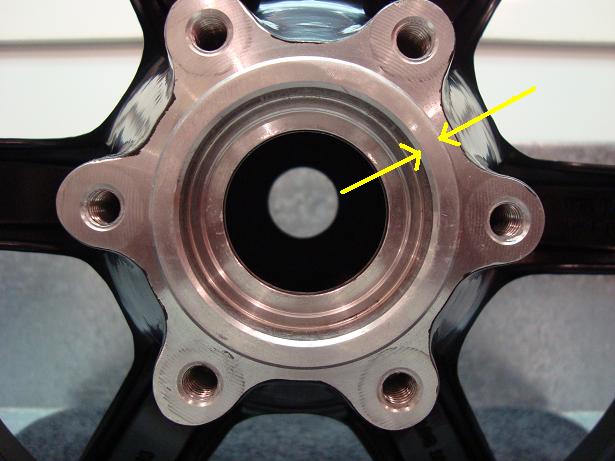

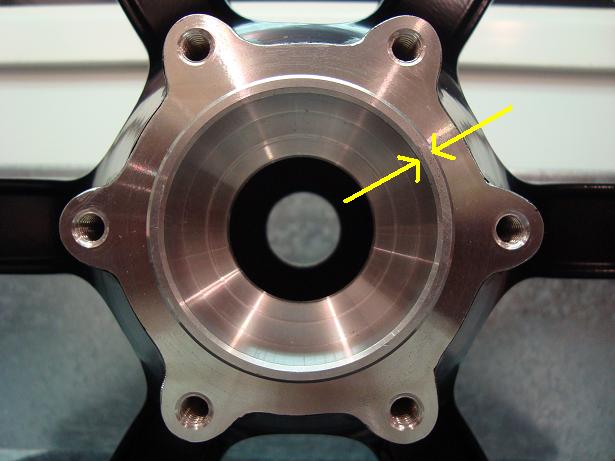

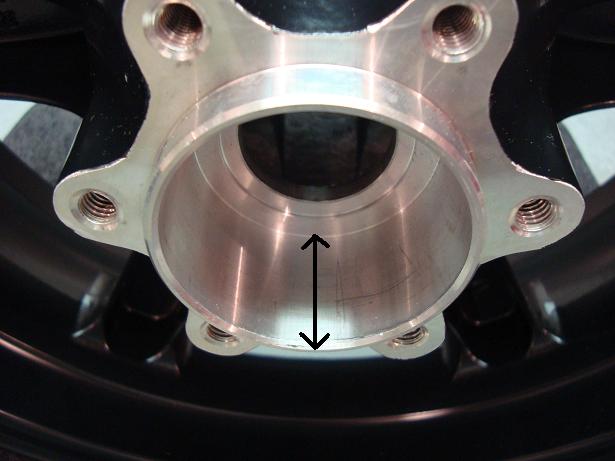

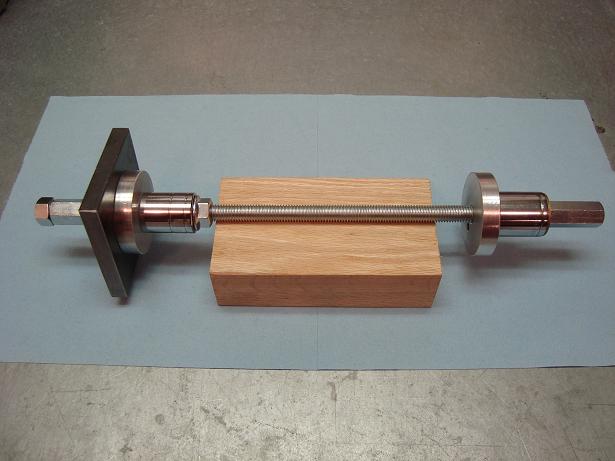

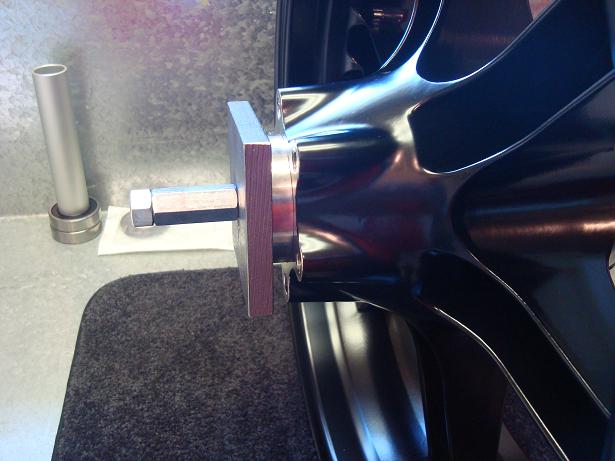

For those of you who may be contemplating the 2010 rear wheel upgrade, here are a few pics from when I did mine. As you can see in the pics, there is a huge difference in this setup vs the 08 wheel. As many of you know, the sprocket side bearing on my 08 XT failed at 7300 miles. It was still under warranty but I went ahead and did the upgrade simply for the peace of mind. I made my own bearing installation tool but if you buy the wheel and bearings from Al Lighton at American Sport Bike, he will professionally install the bearings in the new wheel for less money than it cost to build my own tool. The only reason I did not buy the wheel and bearings from Al is that my dealer gave me a real good deal on parts, since the bike was still covered. Otherwise, I would highly recommend American Sport Bike. Also, to remove the outer race of the failed bearing from the 08 wheel, I just welded a washer inside the race and pressed it out from the other side. I now have a perfectly good 08 two-bearing wheel that I could use if something ever happens to my 2010 wheel. Until then, it will look good hanging on the shop wall for decoration. Also, at the same time, I installed a new Pirelli Angel rear tire. Man, what a difference compared to the worn tire! I wish I could afford to replace my tires about every 1,000 miles. It handles like new again! Bearing failed, 7300 miles:  Pieces:  Old race removal:  2008 wheel bearing bore:  2010 wheel bearing bore:  2010 Dual bearing side. Notice depth:  2010 left, 2008 right:  2008 left, 2010 right:  Spacers, 2008 top, 2010 bottom:  Axles, 2010 top, 2008 bottom:  Additional seals:  Homemade bearing press. The aluminum disks are .500 X 2.400 inches and are very important. The inner and outer races must be kept on the same plane during install or all of this work is for nothing. A very specific procedure must be followed to install the bearings correctly:  Bearing install:  Bearing install:  Don't forget the spacer!:  Brake rotor side with seal installed:  New Pirelli Angel:  | ||

Court |

Great write up . . that gets printed and put in my service manual. Thanks! You're not going to be selling any of those installation tools are you? Is so, put me down for one. | ||

Nobuell |

Great writeup. The 2010 wheel is one of the best mods for the money. It is amazing how much more bearing is in the new wheel. Significantly larger bearings all around with the pair on the drive side. I ride much more confidently knowing I have a 2010 wheel. | ||

Danair |

+1 | ||

Motorbike |

Court, I had a co-worker/friend machine the 2 aluminum disks for me and another friend cut out the square piece of steel for the tool. The function of the square piece is to hold one end of the threaded rod solid while installing the first ( rotor side ) bearing. That end of the tool can be assembled permanently, just flip the tool over to do the other bearings. The rest of the tool is made of parts and pieces commonly found at your local hardware / tool store. If I had machining tools to make the aluminum disks, I would be more than happy to make a tool for you. If you know someone that can machine the disks for you, I will gladly provide you with a detailed list of the parts I used. I think this tool will work for front bearings too as the fronts are not recessed into the hub like the rears are. The socket on the left side of the tool in the pic is to hold the bearing spacer in place during the install. The other socket on the right side has a bushing in it to hold the socket in line with the threaded rod. The bushing is simply a locking collar with a 1/2" hole in it that I press fit into the socket. This helps to ensure that the disk is pushed in squarely so the bearing goes in straight and the socket pushes more toward the outside diameter of the disk. This simple tool worked great and actually was kinda fun to use. Thanks! | ||

Court |

Thanks for the kind response. I may take you up on that offer to provide the parts list. If I can find someone to machine the pieces it'd be good to have around here . . . to loan to the local NYC Buellers. | ||

Motorbike |

Also, if anyone in my area, SE MN, needs help with installing a 2010 rear wheel and bearings, please let me know. | ||

Blake |

Outstanding thread Al! Thank you for taking time to document and share. | ||

Charlie_zulu |

Nice pictures and write up. Pretty obvious how much more robust the 2010 set up is . | ||

Tootal |

Just a tip: When removing an old outer race you can do what Motorbike did but if you have the welder to do that you can just weld a bead across the race in a couple of places. As the weld cools it will shrink the ring and you can just pull it out by hand. Welding the washer in there did the same thing and gave you a handle to push/pull it out. Well done. | ||

Alchemy |

Cool pictures and very informative. Thanks!! | ||

Trevd |

Motorbike, Thank you for this great post! I've never been clear about why the 2010 wheel is supposed to be better, but you've made it very obvious. Thanks! Trevor | ||

Motorbike |

You are all very welcome! I will be posting a list, along with more pics, of parts needed to make the bearing install tool as soon as I can. I just can't do it while at work. Maybe tonight or tomorrow. Thanks. Also, if you already have a good hydraulic press, all you need are the aluminum or steel disks to hold the inner and outer bearing races in line with each other and you are good to go. The press that I have access to use is kind of twisted and warped so I chose to build and use the tool shown. | ||

Electraglider_1997 |

Motorbike, Greatly appreciated photo tutorial. These are the kinds of do-it-yourself guides that take most of the guess work out of doing your own bike maintenance. If I ever open the wallet to buy one of those nice 2010 setups I'll certainly use your method. Side note. That first photo shows rust. That can be prevented completely with a nice coating of Permatex never seize. Only mentioned for those that will try to keep going on their 06/09 rear wheel setups. It has kept mine going with the orange sealed bearings for 34,000 miles. Do wish I had that 2010 wheel though. Wish list. | ||

Motorbike |

That first photo shows rust. Electraglider_1997, you are right. The edges of my bearings had rust from the day I bought the bike new and only got worse from that point. Now if my 2010 bearings get rusty, I will never see it because they are covered by the additional seals. | ||

Electraglider_1997 |

Motorbike, Are you able to easily reach in and check that innermost bearing for function? Seems that you should be able to. I'm wondering if there is a double row sealed ball bearing that would fit instead of that single row bearing. | ||

Motorbike |

Are you able to easily reach in and check that innermost bearing for function? Eectralider_1997, I experimented with that a little when I assembled the wheel. Since the rotor-side bearing, spacer, inner and outer bearings are essentially all pressed up against one another, it would really be hard to tell which bearing would be going bad, if suspected. You would have to spin all 3 bearings and the spacer at the same time and if any roughness is felt, it would be best to replace all 3 bearings at that point. I'm wondering if there is a double row sealed ball bearing that would fit instead of that single row bearing. I too wondered about a double row bearing but did not do any research on it. I figured the Buell engineers must have already looked into that option. Maybe it was cost prohibitive? | ||

Electraglider_1997 |

Motor, You'd think so but my rear wheel bearing inner races turn freely with my finger even though I'm sure those inner races contact the spacer at least after the axle is torqued to spec. On my front wheel, the spacer can be seen and touched since the hub is open. When the axle is removed the spacer is loose between the bearings until the axle is reinstalled and torqued to spec. Then it is solid to both bearings, I just checked to make sure I was stating a fact and the spacer won't turn. Maybe when the axle was out the spacer was just moving with the inner races, I just can't remember except that it seemed kinda strange. I've had no bearing failures in my 34,000 miles. | ||

Motorbike |

After I installed the new bearings and spacer in the 2010 wheel, I was able to slide the spacer back and forth a bit but not sideways at all. I could also spin the bearings individually but could tell they were making slight contact with the spacer or bearing next to it. It was all very smooth because everything is new and shiny yet. I'm sure that everything snugs up just right once the axle is properly torqued. So far it's working great! | ||

Idaho_buelly |

Fantastic write up...Thanks! | ||

Jetjock |

My 2007 is still under warranty. Its rear wheel bearing failed rather dramatically last weekend causing significant, unrequested steering inputs & uncommanded intermittent breaking plus an unrepairable wheel & brake rotor with damage to pads & caliper housing, near heart failure in a number of oncoming & being passed cages & one set of new, nearly soiled BVDs & considerable change in plans. The old wheels aren't available from Harley, only the new triple bearing wheel assembly. Harley Warranty says they'll only pay for the original bearing & nothing else. The only way to get the Uly going again is to put on the new/2010 wheel/bearing assembly. This seems wrong for me to pay for what Harley caused. Does anyone have any experience or advice on Harley making this right? | ||

Portero72 |

Be firm but polite, and take it higher up the chain. You could have been seriously hurt. | ||

Motorbike |

It was my understanding that Harley would pay for the entire new 2010 setup if your wheel is damaged. I may be wrong as I have nothing in writing that says that. When mine failed, the only parts damaged were the bearing and spacer. My dealer said Harley would replace the bearing under warranty but if I wanted to do the upgrade, the dealer would give me a deal on the wheel if I bought the rest of the parts at list price. Ended up costing me $362.00. I hated to spend the money but I feel much more at ease while riding now. | ||

Electraglider_1997 |

When I put my new 2010 wheel on this morning I brushed Permatex never seize all over the new axle and axle threads, the outside of the dust seals and over the shiny aluminum that is just outside of the dust seal diameter to keep that from corroding. Machined aluminum corrodes very easily especially if any winter salt spray hits it. The never-seize will keep everything pristine underneath it. Sure, it picks up dust but everything under it will be protected completely. | ||

Richd |

Motorbike....did you make a bearing removal tool? or have it done at a dealer? Just to remove the bearings at my local dealer is $80! | ||

Motorbike |

Richd, my 2010 wheel came with no bearings so all I had to do was install them, along with the spacers and seals. On my original 2008 wheel, one bearing was destroyed so I just had a friend weld a thick flat washer inside the outer race (see 3rd pic above) and then I pressed it out from the other side. Once that was done, I flipped the wheel over and pressed the other stock bearing out. The only reason I removed the bearings in the old wheel was so it would be ready to go if I ever need it someday. To remove bearings that are not destroyed like mine, I believe you have to use a blind bearing puller or a special Harley tool. I have read that the puller will damage your inner spacer so you should replace that too when installing new bearings. (I would replace it even if it was not wrecked, just to be sure it has not been crushed at all.) After one bearing is pulled, it is easy to press the other one out from the opposite side. (I borrowed a hydraulic press from the same friend that does my welding!) Another option would be to weld a nut inside the inner race of one of the bearings. You could then press it out from the other side using a shaft that would push on the nut welded in. Just be sure to get a good weld on the nut as these bearings do not slide in the aluminum very easily. Good luck! | ||

Tiltcylinder |

Motorbike, did the torque spec for the axle change? I've recently changed the rear tire and reassembled it using the old (2009) values. Having the old bearings fail far from home was an experience I'd rather not repeat... | ||

Motorbike |

Tiltcylinder, I don't remember seeing anything in the instruction sheet that said what the torque value should be on the 2010 axle. I will take another look at it when I get home from work today (it will be a while)and report back to you. I torqued mine to 25 ft/lbs., backed it off 2 turns and re-torqued to 50 ft/lbs., which is the spec for the 2008 axle. Now you have me thinking..........I better check into that. (Message edited by motorbike on September 29, 2011) | ||

Electraglider_1997 |

I really doubt that the pre 2010 torque specs would be any problem for the massive by comparison bearings. | ||

Motorbike |

Same here but I am going to check anyway. I have the 2010 instructions filed in my workshop. Thanks. |