| Author | Message | ||

Uly_man |

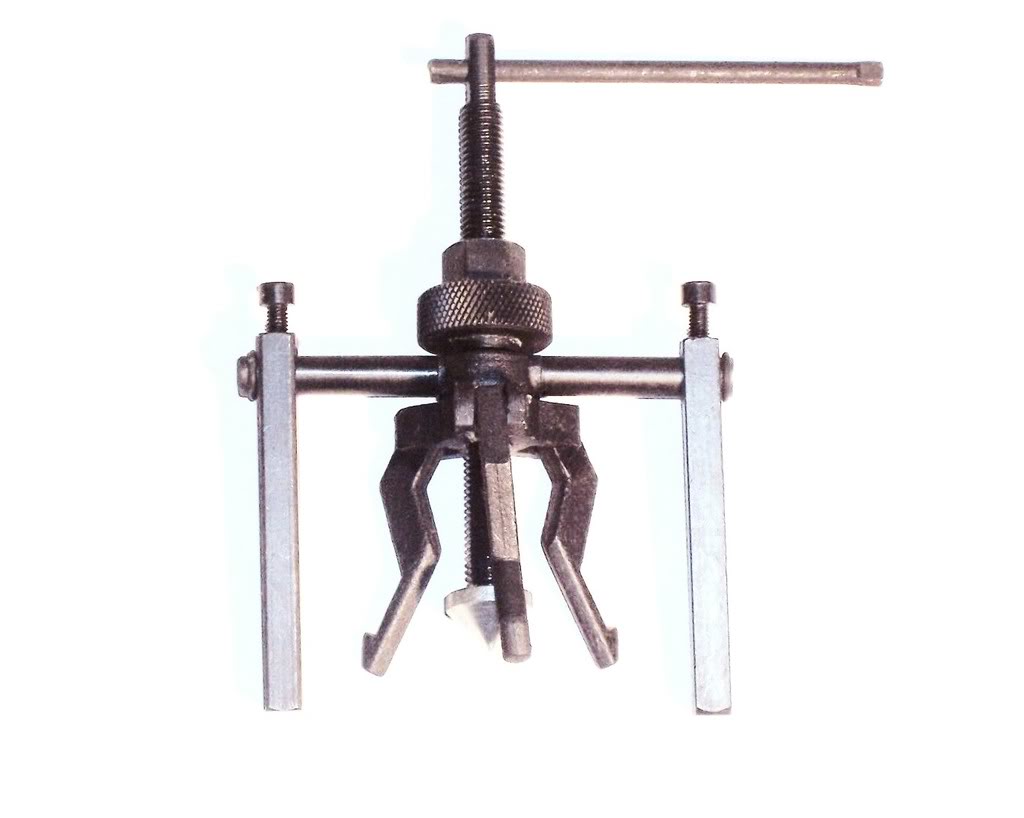

I used this tool, to extract the wheel bearings, and it is a good for home use, well made and cheap. I abused it VERY badly and it was still fine. The design of the "tube-to-bearing" leaves little for the claws to get a grip on but it will with a little effort.  What I did, before fitting the new bearings, was to file out three grooves on one end of the tube, to match the puller arms, to help with the next bearing change. I do not see that as any problem myself. The bearing on the other end is then easy to pull or drift out. Add a little Copper grease on the bearing to help extraction the next time around. Worked great for me but it is up to you how you would do the work. | ||

Swampy |

I tried the Harbor Freight made POS, and it did not work, the reverse jaws bent inward. I ended up using an internal expanding type puller that really gripped the bearing. | ||

Electraglider_1997 |

Swampbeast show us a photo or rob a photo of it off the net for us. | ||

Swampy |

This one worked, but.....I used the slide hammer to pulle it, I tried to pull it out as straight as I could so I would not damage the hub bore.  Installation was done with a threadded rod and some big bearing driver pieces to seat the bearing on the brake side first(May be wrong, check the manual) then set the spacer in and then pulled the other bearing in until it jus seated on the spacer, you can tell when to stop tightening by how it moves while it is going in the hub. | ||

Djz |

just weld washer to inner race and punch out | ||

Swampy |

The problem with driving it out or driving the bearing back in is that the hub is made of a very soft aluminum and if it starts out crooked the bearing recess will deform and not hold the replacement bearing securely and the bearing will spin in the hub. | ||

Djz |

Swampy it is a good way to pull the bearing .It is clean and simple i think less chance of damage than inner puller Maybe you know Al at american sport bike it is how he recomends.if you weld to outer race it shrink and come better.but by all mean do as you see best for u | ||

Uly_man |

They can be very tight due to a little corrosion on the edge of the bearing. Once this is broken they come out easy enough. I hope a little Copper grease will help the next time around. They should be fitted with a press rig but can be done without one if you take great care doing it. I had a worn hub on another bike, I did not do it, and its a new wheel job to fix. |