| Author | Message | ||

Xcephasx |

okay, i just ran into/through this problem myself. finally ended up relocating the ecm to the space between the fusebox and the battery. i'm holding it in place with velcro. seems to be working. also, i'm only 150#. kind of ridiculous that this problem exists | ||

Xbimmer |

...within 5-years or 18,641 miles (or 30,000 kilometers) whichever occurs first That's a joke, I hit that mileage within the first nine months. Tried to get my carbon canister replaced last year the service writer just shrugged and said "sorry". Aren't cars covered for 50k or more? | ||

Froggy |

8 years/150k miles on cars. | ||

Pauley2000 |

RWVEN, that's what I wound up doing. Thanks. redbuell_really_gives_you_wings, Same wear pt. on my seat pan too. The lightning has their ECMs stuck in vertically. These just stick up like a sore thumb. -p | ||

Rwcfrank |

Those of you who heated the seat and pushed where the block is rubbing are going the wrong way. You need to push in the seat pan where the connector is touching not the block. Dimpling the seat base where the block touches effectively lowers the seat pan onto the ecm.DAMHIK its closer to the hole. | ||

Redbuell_really_gives_you_wings |

^^ I figure the seat underpan design/strenght will be the seat support, not the ecm chock. By pushing the rub mark in, the seat should bottom without resting on the ecm in any way. If i had chocked the rub area up, it would be in full contact all the time and taking all weight transfered by rider... no thanks. | ||

Husky |

I got the cracked ECM replaced in Glendale. Ran fine on the way home, Warranty repair! Last ECM available in So. Cal husky | ||

Balloyd66 |

Had the electrical cut out again the other day, and looks like my fat a$$ had cracked another ECM, right around the gray connector. See some rubbing marks on the end of the connector, also. Haven't called the dealer to see if they'll replace ANOTHER one under warranty. Can someone tell me, is it the flexing of the connector that causes issues or air/moisture getting inside the ECM, or what? Could I just silicone the cracks and be fine again? I'm sure going to relocate the thing this time, though! Any input? | ||

Motorbike |

For those who have had the ECM cracked, how bad is it cracked? I was looking at mine again last night and I can see that the seat is just starting to rub on the gray connector. I pushed down on the connector a little and can just barely see a feather edge of the epoxy if I look through a magnifying glass. I'm not sure if mine is damaged yet or not. Pictures anyone? I am not going to ride mine anymore until I figure out how to keep the seat from hitting the connector. Thanks everyone! | ||

Rwcfrank |

I added a 1/4 spacer to the block and dimpled the seat bottom. I have a piece of thick aluminum coated insulating tape stuck to the top of the ecm to show signs of seat contact and so far with the fix it doesn't touch at all. | ||

Rays |

This is typical of the inside of the ECM - the connectors look big and tough but the circuit board and the traces are relatively frail. The cracks in the potting around the connectors are really only an indication of how much flexing has occurred - the real damage will be a broken circuit trace/s and the most likely location will be where the connectors are soldered to the circuit boards. There are multiple ways to prevent pressure on these connectors as described in this and many other threads - choose one that suits you. This is a critical component and if damaged will cause you untold grief - don't leave it up to chance.  | ||

Tastroman |

For those of you who have noticed cracking, did you replace it before experiencing problems or did you replace it as soon as you noticed a crack? | ||

Balloyd66 |

After experiencing problems the first time, and now (again) I'll have to see if HD will warranty the second one. Did relocate it last night, though. @ Rays: Like your last post. So if I did already experience an electrical hiccup, then that means somethings already cracked inside and spackling the cracks probably won't help? | ||

Tastroman |

For those that have added a second spacer block to the existing block, how did you go about mounting it? | ||

Redhat |

Checked it out earlier, the black connector rubs against the seat. Just had a look at it, and when i press it down, a crack appears between the connector and the housing. Have a second block ready to mount on the rear bolt, but of course now i need a different bolt. Seems to work tho when i put it in place loosely. | ||

Motorbike |

I tried mounting a second block on the rear ECM mount on my 08 XT. I had to take it back off because the seat would not fit without using excessive force to push it down and forward. It almost worked but not quite. The problem was not the height of the rear block but the position. It was hitting the edge of the recessed area on the seat base so I could not slide the seat ahead then down to latch it. Oh, and yes, I had to use a different allen-head screw to mount the second block. Thanks. | ||

Xcephasx |

Seriously, just relocate the dang thing and be done with it. | ||

Husky |

I bonded the extra spacer on top of the OEM spacer with Shoe Goo, from Target, Orchard, Walmart etc. Husky | ||

Tastroman |

Mine is cracked where the gray connector enters the ecm. The ecm itself has a small crack in it but my bike is running fine. I called the dealer about a replacement but they said they would have to look at it before they could order a replacement. Will they replace one of these if the bike is still running ok? | ||

Pauley2000 |

I took mine in last week (just the ECM) and showed the service mgr. He had another one in three days. Just need to take the bike in now with the old (stock cracked) ECM re-installed. +1 to relocation of ECM a-la Rwven method. My Erik Buell Racing race ECM will probably NOT be warrantied if it cracks. The other XB models have better protected ECM's with the lightning's tucked right in, and the Thunderbolt's under the windscreen. IMHO move it or risk losing it again. Tastroman: get them to replace it, show them the problem on the bike, refer them to this thread if necessary. -p | ||

Blasterd |

Tastroman, my bike was running fine as long as it wasn't raining. In the rain it spit and sputterd. Get them to replace it | ||

Uly_dude |

when I did my comfort kit, I put a pliers on the metal support(part of the battery cage)that holds that end of the ECM up. with the ECM off at the time I bent the metal support back n forth while forcing it down. This lowered the metal secure point on this high side of the ECM down about a 1/2 inch. Plenty of room for the seat pan now it seems. | ||

Nobuell |

Uly dude +1 on bending the bracket. I did the same thing when I installed my comfort kit. There seems to be plenty of clearance now. | ||

Nptuly |

I had a speratic engine cut out from a damaged ECM for months. Just had it replaced last week and bent the metal bracket down. It runs great now. | ||

Motorbike |

Can someone who has had a cracked ECM please post a pic of the damage? I would like to compare your ECM to mine. I can see just the very slightest feather edge on the epoxy where the gray connector enters the ECM box. I can only see that if I look through a magnifying glass. I really doubt that mine is damaged enough to replace it, or at all for that matter. Also,I gave in and am in the process of relocating the ECM. That seems to be the best way to make sure the seat never hits the ECM again. I am fabricating a small bracket to hold the ECM in place and keep it from vibrating. It will be relocated to the space in front of the battery, directly over the shock oil reservoir. Too bad the wires aren't a little longer. I'll post a pic when I'm done with it. Thanks. | ||

Tastroman |

The dealer agreed to replace my cracked ECM under warranty. Now on to the fix. I'm thinking about cutting a 1/4 inch piece of plywood and gluing it to the top of the ECM. The plywood would rise about 1/8 inch above the existing spacer. Has anyone learned the hard way not to do this? | ||

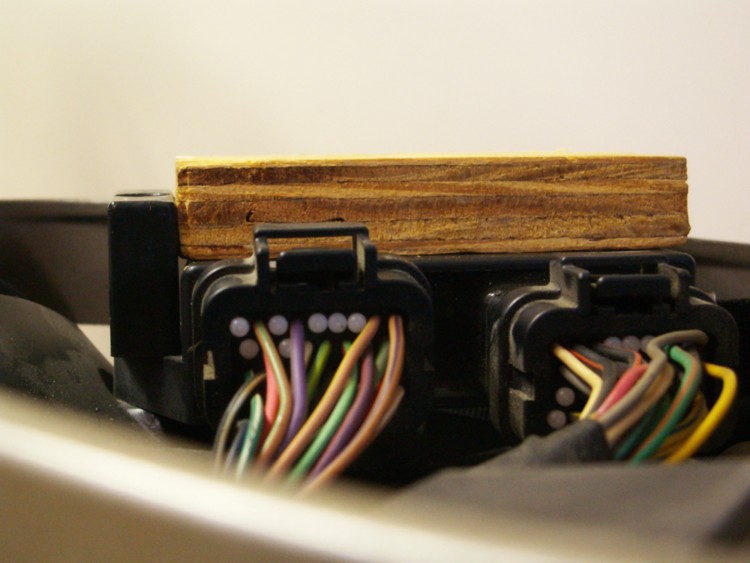

Tastroman |

This is what I'm considering.  | ||

Balloyd66 |

I don't recall ever having that spacer on my '09 XT. Is it stock on all Ulys? Did someone lose it or did I get ripped off? | ||

Tastroman |

It came stock on mine but the ECM connectors still rub the seat pan so it does not do much. | ||

Xcephasx |

Relocate, relocate, relocate! |