| Author | Message | ||

Jonsocal |

OK, I am going to replace my 77 connector on my '06 Ulysses. I did purchase a new 77 connector, but why? Couldn't I just use a bullet type of connector instead? (Hey, I'm no mechanic so your input is greatly appreciated.) | ||

Froggy |

Many have replaced the connector with various other fittings. If it makes good contact, waterproof, and can handle the current then go for it.  | ||

Jlnance |

There is a kit from HD with updated connectors. I think it costs $19. The advantage of the kit being that when your voltage regulator dies (it will) you have the correct connector for installing the replacement. | ||

Motorfish |

Especially if your on a road trip. Easier to plug n play. | ||

Etennuly |

I simply cut the wires at both sides of the failed connector, soldered them and used heat shrink. There is no reason that could not be done if you have to come up with a VR on the road somewhere. | ||

Bluzm2 |

Anyone got the part number for the replacement 77 connector? | ||

Froggy |

Y1312.02A8 is the connector service kit, only needed for 2003-2007 XB models. | ||

Motorfish |

I was just thinking, if I where out on the road, it would be one less thing to locate,(solering iron and heat shrink). The less stuff you have to get when broken down, the better. Cuts into riding/vacation time. I don`t recall any of the new, `08 and up, connectors failing. I also used some anti-corrosion compound ,used on electrical connections and pipe(aluminum),on the new plug. | ||

Bluzm2 |

Thanks much Frog, I should replace the one on my 06 X before it melts itself down. | ||

Electraglider_1997 |

I checked my 77 connector and it looked good as new. Just a few hundred off 30,000 miles and I even have the original fan. I know it will go tatas up eventually but my point is that some parts last a long long time. If you are submerging your bike in creeks or pressure washing it then you'll pay the price much sooner. I never wash my bike except to ride or park it in a downpour now and then. I wash the windshield now and then with a soapy towel so I can see. | ||

Buelet |

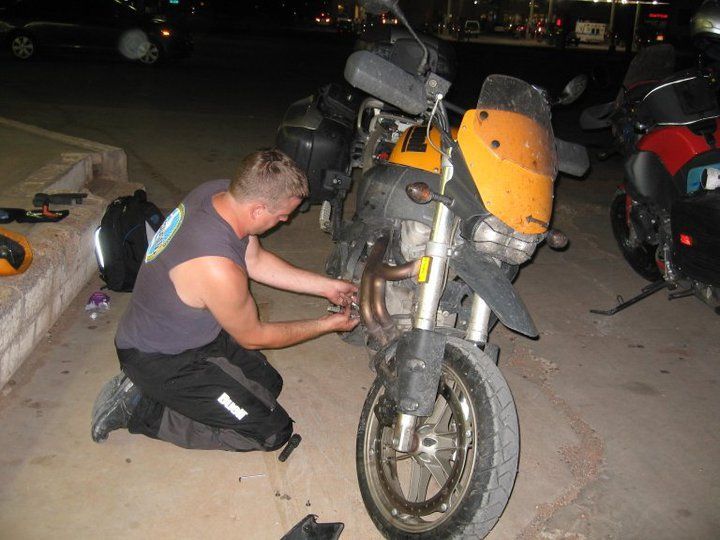

Hey - To each their own, but what's wrong with doing a little DIY while on vacation? That's what memories are made of... And it was on my birthday too!  | ||

Buelet |

Another shot of my "77 Connector" experience in Tuba City, NM from earlier in the trouble shooting process. (Around 36,000 miles on the bike at this time.) This roadside repair made possible by many hours spent perusing BadWeb!) Thanks to all who contributed!  And Again once we were closer to home about 7 days later.  | ||

Xcephasx |

i bypassed mine entirely when it failed. got some quality butt splices and liquid electrical taped and wrapped em up. they probably are only there so it's easier to put the bikes together in a factory. | ||

Electraglider_1997 |

Really made no sense to put those connectors down low on a "Adventure" bike. | ||

Ratbuell |

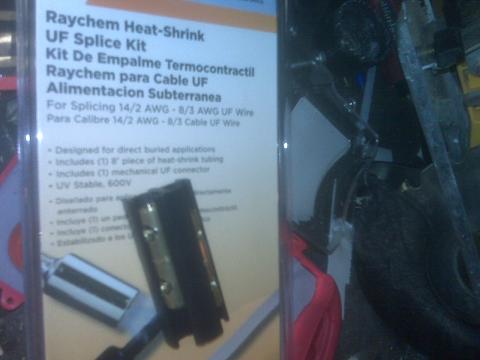

Here's my fix, from Home Depot (sorry for the crappy cell phone pics):   Screw terminal fittings, still a "connector" if VR removal is required in the future, and no issues at all since installing (about 3k miles). | ||

Gunut75 |

Awesome Ratbuell! Thats another thing to add to my tool kit. | ||

Ratbuell |

...just be sure to note the un-shrunk heatshrink tubing in the first photo, below and to the right of the connectors. After the pic was taken, I heat-shrinked the connections. | ||

Johnboy777 |

Ratbuell Do you need to Loctite the screws? Just curious . | ||

Ratbuell |

Nope. Stainless screws in a brass fitting...they've been nice and tight for over 3k miles, and the Kuryakyn voltmeter shows nary a quiver in output  Besides....loctite is an *insulator*. Not a good thing on electrical items. |