| Author | Message | ||

Thesmaz |

Hey all, I was working on the Uly today and snapped an exhaust header stud on the front jug.... I'm putting together a parts order and wanted to get some opinions on either using a heli coil or nut sert after I get the broken stud out. I've got the drilling guide and 4 new stud, seals on order and I just want to make sure that I have everything on hand when everything gets here. What is the length of the studs? I'm guessing that the portion of the studs that goes into the jug is left hand thread, correct? I'm not looking forward to rotating the engine but I've got the bike ripped apart doing a bunch of other stuff so whats another couple of hours right... TIA! (Message edited by Thesmaz on April 04, 2010) | ||

Bdrag |

Not sure on the thread direction. If ya get the broken stud out without doing damage you shouldbe o.k. Try to soak the broken stud with some penatrant oil first. Also once you figger out the thread direction try using a drill bit that will back the stud out as you drill. Sometimes ya get lucky and the stud will back out if drilled with the correct direction bit. They do make left and right hand twist bits. Good luck! BDRAG | ||

Reepicheep |

There is a decent chance with the Jims tool that the old stud will spin right out. If not, I'd personally start with the heli coil, then if that fails, drill the next size up and retap, and if that fails, do the timesert... I think each successive size will work, but you might want to double check the math. Basically, I go from least to most invasive. | ||

Ratbuell |

I think the studs thread into the heads RH thread... | ||

Ulyranger |

My first attempt would be; penetrating oil - drill hole in stud (matched to appropriate E-Z out) - heat surface carefully - use tap style EZ out to remove stud. An alternative to the EZ out is a reverse thread bit for the drill. I like the slow 'n easy tap method myself. If that fails I go the heli, 'cert route. | ||

Natexlh1000 |

The studs on my X1 are RH. Would doubt that the XB engines are different. | ||

Yool |

I've just had this job done on my '07 Uly by the dealer. Threads in the head are 5/16 UNC right hand. The nuts are a finer thread. Check your new studs to verify this. According to the mechanic::: The OEM studs are fitted with Loctite, fairly difficult to extract. They drilled and fitted a Helicoil.They prefer this cause the helicoil is stainless, and the profile of it makes it grip the alloy head better. (I also heard that if you loosen the rear nuts, you may be able to swing the headers far enough out of the way to avoid rolling the motor) Good Luck, let us know how you go  | ||

Reepicheep |

Skip the easy out and use the Jims tool. | ||

Bluzm2 |

Like Bill said just above. DO NOT USE AN EASYOUT! Unless of course you like grinding out hardened steel with diamond dremmel bits. Use the Jims tool. If memory serves, the bit that comes with it IS a left hand bit. If done carefully, you shouldn't bugger the threads using the Jims tool. I used one once a while back (4 years ago?), it worked perfectly. I put in a new stud and it's still good to go. | ||

Tootal |

DO NOT WASTE YOUR TIME WITH A HELICOIL! Helicoils suck in aluminum, use a timesert or keensert. I've been down this road before and learned my lesson. Actually I didn't have any choice at the time but had to redo it at a later date because of it. I've been a Machinist for 32 years and I still don't know everything but on this subject I have too much experience! Think long term, just sayin... | ||

Reepicheep |

Any more details Tootal? I had heli-coils in aluminum engined street bikes for 100k+ road miles (and lots of dirt miles) and don't think I have had any fail... What kind of failures are you seeing, and in what kind of applications? Maybe I have just been lucky... | ||

Reepicheep |

Oh, and Brad, the second time I had to do this (knew better then to use the easy out, but managed to break a tap in there) I found that a bullet shaped tungsten carbide dremel bit does a lot better then the diamond grit ones. It'll take two to three of them to get the easy out out, and you will be weeping little razor sharp pieces of steel out of your hands for a month afterwards. | ||

Ratbuell |

OK Tootal - I'll ask. It's non-Buell (and sorry for a semi-hijack), but I'm reassembling the engine for a 1991 Spirit R/T with the Lotus 16v turbo head (aluminum head). Can't booger the head too bad...they're unobtanium, replacements don't exist. At least, not for less than the cost of replacing the car. One of the exhaust stud ports is stripped in the head (threads pulled out of the aluminum) - the fastener at the end of the manifold, not a center one (fasteners are arranged in a triangle around each of the ports, one top, two bottom). Cast iron manifold with 5/8" flange, steel-ring gasket, aluminum head, 40 lb-ft torque spec on the fastener. I'm going to get (a helicoil?) the repair tools/pieces today - would you recommend a helicoil? Time-sert? (Message edited by ratbuell on April 06, 2010) | ||

Thesmaz |

Thanks for the tips, parts are on order (some of them are on back order) and I'll update my progress. | ||

Reepicheep |

I don't think there is much argument that the TimSerts are superior... they are. But they are also $100+ and mail order, versus the $29 at my local auto parts store on a Saturday afternoon. So the question was "are heli coils good enough", which I have always found them to be. If I had an unobtanium head, I would not only use timserts, but I would have a machinest install them. Or send them to Wes Brown to be welded. | ||

Glenn |

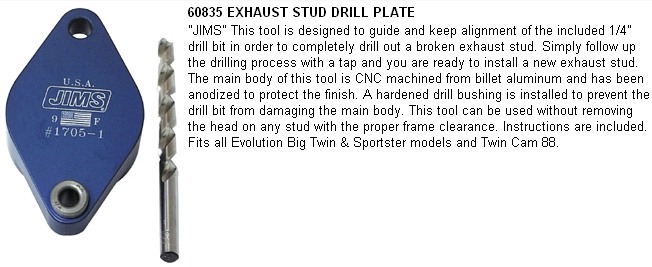

I never herd of Jims tools so did a little searching and posting it here for the record.  | ||

Tootal |

Ratbuell, if you are putting 40 ft/lbs on a stud then try and find an insert. I know what your talking about, we have a BMW 2002 race car and the head has some major money poured into it so screw ups are not allowed. I have found that the aluminum used in heads is a little better than what Harley use to use on the evo cases however if you can possibly get an insert it would be peace of mind. You can try a helicoil and if it fails then you can still drill bigger for an insert. If it's easy to get to then you might take a chance but if it's a pain I wouldn't take the risk. If you have access to a lathe you can make your own inserts out of stainless. Take a stainless bolt larger than your stud and cut the head off and chuck it up in a lathe and drill and tap the thread needed for your stud then part it off the length you need. Drill and tap your head for the inserts thread. Run a nut on the new stud and thread on your new insert and lock down the nut. Put some red or green loctite on the insert and install a few thousands under the surface and let it set up overnight. Remove the nut and stud and run the stud in with blue loctite. I've never lost a thread doing this. Good luck, it sounds like an interesting project! | ||

Reepicheep |

Good real world info Tootal, thanks! | ||

Sprintex |

Just a thought. http://www.cammann.com/ | ||

Tootal |

Looks similar to an edm machine. (Electrical Discharge Machining). We used it for broken taps that threaded the holes in the end of axles for rail cars. It's slow but very accurate. |