| Author | Message | ||

Snub13 |

Last year at the Liberty H-D Open House I had a rear wheel bearing meltdown. Rented a U-haul, the dealer replaced the entire rear end. The dealer was very nice and understanding. Court gave great advice and assistance (Thank you , again)     As per many sage Badwebbers, there is a VERY specific rear wheel torquing procedure and if it's not done by the book, you have problems. I had just had the dealer put on Scorpion Syncs. Fast forward to June 2007. Mrs. Snub and I rent a Uly from Alaska Rider Tours (who just put on new rubber) and seven days (and 2,270 miles) into the trip and....   Not wanting a complete melt down many miles from any cellular coverage, we called AK Tours. The folks at AK Tours were great, but they only had a 650 Vstrom to swap with us!  I love the Uly! It is a fantastic all around motorcycle. But, WTF is up with these wheel bearings? I understand the whole torque thing, but it seems clear (to me at least) that at least two "Harley Certified Mechanics" don't have ANY idea about the sequence! Am I the only one having this problem?...Is anything being done to fix this?...Can anything be done to fix this?.....Can Erik "dumb down" the sequence so Mongo the "Certified H-D Mech." can understand it????????????? I'm not a "Certified H-D Mech." and I can understand it?<>?"?:<?l:"><?>:"   Now, naturally after the same problem with two different bikes, I am ultra paranoid! The only reason I noticed the rentals' bearing was because I was already paranoid from when it happened with my bike. How do you feel any confidence on an "adventure sportbike" (adventure being the operative word) when this is going on? I'm all about roadside repair but it might be a little tough to take the needed tools on a trip. Stop...deep breath....hold it....let it out...OK, sorry! Tim PS: to top it all off, When we got home my wifes SUV was still being worked on, she took my truck to work, I pulled out of the driveway on the Uly and......my F!@%ing belt broke! At least I wasn't on the highway....Of course my dealer dosen't have one in stock and with the holiday I have to wait until next Saturday! I sure hope Mongo remembers the torque sequence when he puts the wheel back on! (Message edited by snub13 on June 30, 2007) | ||

Bertotti |

Heck now you've gone and made me paranoid. I'm running out to check my bike now! | ||

Iugradmark |

Guys, What do I look for? | ||

Wolfridgerider |

Snub13 I have a extra Uly belt.... if you need it. Just let me know. It is good as new. I went with a Saintly Chain drive after my belt broke with 9200 miles on it. My belt broke on Sunday and I was riding on Wednesday. Buell sent a replacement to my dealer UPS Next day air and I am very pleased with the way Buell handled it. Your Dealer should have marked the Downed vehicle box and you would have new belt by now. It sounds like they didn't give you all the customer service that they could have. IMHO. BUT.... If you need my belt to make it to Homecoming or are going to miss some super ride let me know and I will UPS NDA it to you on Monday or I could meet you half way between Columbus & Pittsburgh on Sunday. (Sunday is a good day for a ride.  ) All I ask is you pay for the UPS charges and send me the belt back when your new one comes in. I like to have a spare... just in case... the chain breaks.... ) All I ask is you pay for the UPS charges and send me the belt back when your new one comes in. I like to have a spare... just in case... the chain breaks.... Send me a PM if need be (Message edited by wolfridgerider on June 30, 2007) | ||

Teeps |

Are wheel bearing failures due to seal failure or is the rolling element of the bearing failing? How does not following the torque procedure in the book cause either to occur? | ||

Ft_bstrd |

After having to stand on the wrench to get the rear to break loose because "mongo" torqued it down with an impact wrench, I don't think I will want to have the dealership do anything with the wheels. I think it's a short cut that the dealership techs are doing to save time that doesn't bite them in the butt when it comes to HD bikes but is very detrimental to our bikes. I think a contributing factor is the failure to do the initial torquing to seat the bearings and then re-torquing to spec. If you just slam the impact wrench on it, you torque it down to a higher than recommended spec without properly seating the bearings. I still value my dealer and believe that they do a good job, but this is a specific instance where I have evidence that they aren't quite doing it by the book. | ||

Chadhargis |

I'm the one that had to stand on my wrench to get Fatty's wheel off. I weight nearly 240lbs, and the thing didn't budge. I had to pound it with a rubber mallet. I am the only person to ever remove or replace my wheels and my bearings look fine. I follow the instructions in the service manual, and use anti-sieze as specified. I even put a thin coating of grease on the axle just for corrosion protection. I torque to 25ft/lbs, back off two turns, then torque to 50ft/lbs. | ||

Lorazepam |

I am sitting with bad wheel bearings as we speak. I jacked the bike up to put new tires on, and grabbed the rear wheel, and it feels an eighth inch movement of slop. 13k miles, and I put the first set of tires on, and followed the manual. I coated the axle with a thin coating of waterproof grease, and it came out without much trouble. 10 of the 13k have been 2up, 5k with loaded bags. There is a pic of me and my former gf in the fuell pictorial from last year's homecoming. I also ride in all weather. I am bummed. It feels like I have a cursed bike, and my confidence in it is starting to fail. No homecoming for me this year unless I ride the airhead up. I think I am going to sell the Uly and get a bike with a centerstand. You are stranded, and cant remove the wheel along the road without one. | ||

Etennuly |

I think I am going to sell the Uly and get a bike with a centerstand. You are stranded, and cant remove the wheel along the road without one. Just for the sake of knowing it can be done.....My shop jacks were occupied on jobs several months ago when I was ready to remove my rear tire for replacement. I got wood blocks that amounted to 1 1/2 inches higher than the bottom of the rear of the muffler. I loosened all that needed to be and tilted the bike onto the side stand and had my son slide the blocks under the pipe. It held the bike securely with the wheel off. It was so much quicker and easier than dragging out the ole' jack, I used the same method a few weeks ago when I replaced the front tire. | ||

Windrider |

I think that two main factors can damage Uly wheel bearings: 1. Improper or careless wheel removal/installation. Any side torque on bearings is bad and if you have to use a lot of force to get the axle out or in it will stress the bearings. If you follow the procedure in the service manual I don't think that you will have any problems; it is a very good procedure. Sadly, the Buell mechanics that I have witnessed at work don't follow the procedure. 2. The Uly wheel bearing design lacks adequate protection from dirt and mud to the seals for a bike that can be ridden in "adventure" conditions. There should be some secondary form of a dust seal to protect the bearing seals from damage in mud, gravel and dirt IMHO. Just my 2 cents. Etennuly, that is a great idea! Lorazepam, I have heard stories of other Uly riders putting the bike on it's side on the bags to remove a wheel along the roadside. Never had to do it myself.... yet. | ||

Snub13 |

Hey, thanks guys.....I'm not alone! Wolf, thanks for the offer, I have to work during homecoming this year (and we just came bake from Alaska). I'm not going to be able to do much riding anyway so I'll just wait on the dealer. But thank you. I think I'm going to order another belt so I have a spare too. | ||

Adamd |

Why don't we stop using those crap bearings and use a high quality bearing? | ||

Teeps |

Adamd, The bearings are not "crap" as you say. And, a mishandled (installed) bearing is doomed to early failure, regardless of its quality. The problem with the (Buell chosen) bearings, IMO, is they lack a "proper" seal, for the environment they are used in. This type of bearing choice is great for the "fair weather" rider, like me, the race track, and as a bonus; is cheaper to manufacture... | ||

Bearly |

It seems in the service world, it's the new guy that gets to change tires and the oil on bikes that come it. I guess that 1/2" drive torque wrench (or breaker bar) in hand with 3/4 socket and figure that they need to get serious with it. "48-52 ft lbs, Oh that can't be enough!" I can't even find anyone that knows how to balance a tire. No matter what kind of fancy machine they have. So I do it myself. When I need bearings, I'll buy the puller. I may have not had complete disaster stories to tell about my dealer, but I read these stories too often! Buy the manual and all the special tools you can and do it yourself. It will save you money and headaches. | ||

Michael1 |

More bad wheel bearings.. Yikes. They are a quality brand bearing and should work just fine...but if you take your Uly off road and ride in the sand, dirt, mud, dust, etc... You have to keep an eye on them. The single lip seal on the bearings just doesn't cut it in an environment that I put my bike through. Good thing they are pretty cheap. I plan on trying a different brand/seal design down the road here. | ||

Snub13 |

More bad wheel bearings.. Yikes. They are Michael1 said; "a quality brand bearing and should work just fine...but if you take your Uly off road and ride in the sand, dirt, mud, dust, etc... You have to keep an eye on them. The single lip seal on the bearings just doesn't cut it in an environment that I put my bike through. Good thing they are pretty cheap. I plan on trying a different brand/seal design down the road here." right.... The bike in question is advertised as "an adventure sportbike" In the promo vids / pics they are on dirt roads and the like. Give us another lip please! Also, they are cheap and you can do the work yourself but when you find a problem in the middle of no where, you're screwed! We already have to keep an eye on and use kid gloves with the stock bags and take an extra belt with you, now we need to mind our bearings.... (Message edited by snub13 on July 02, 2007) | ||

Snub13 |

Hey look at this. We met in Dawson City, nice guy. http://youtube.com/watch?v=7T660XciBj8  | ||

Ft_bstrd |

Cool vid. I would say that as part of any heavy run like that, better bearings and an extra belt would be a must. I am assuming you can get bearings that are sealed better? Between not following manual specifications for torque procedures OR proper specifications but really harsh environments, I think the bearings are gonna have a hard time. I can't even imagine what that wet grit would do to bearings over a fairly short period of time. | ||

Littlefield |

Different bikes use different methods of securing the bearings in the wheel. On the front wheel of my Speed Triple one bearing seats against a shoulder and has a snap ring holding it in. The other bearing does not seat against it's shoulder, the spacer is quite a bit longer than the distance between the shoulders and the second bearing floats. All the side load is carried through one bearing but the torque on the axle is not as critical. I haven't had mine apart but it appears that on the Buells both bearings seat against shoulders. The spacer is probably a few thousanths longer than the distance between the shoulders. Proper torque is important to compress the spacer just the right amount so that the inner and outer races are in alignment without putting the bearings in a bind. The bearing probable have little or no internal clearance so the side loads can be taken by both bearings. | ||

Windrider |

Snub13, Great video. | ||

Jack82 |

I pulled my rear wheel off today to fit a new tyre....I dont have a manual... Is there anything in the manual I need to know when refitting the wheel?? | ||

Bearly |

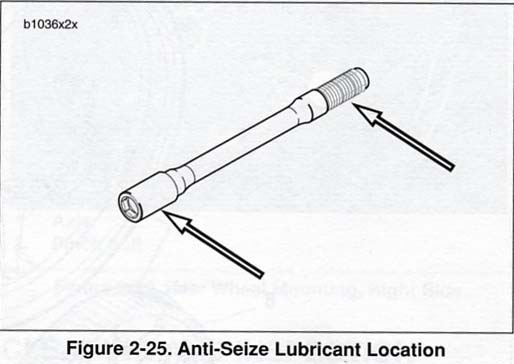

Here's what the 2006 Ulysses manual says. Installation: 1. Center rear wheel in the swingarm at the same time sliding the drive belt onto the rear sprocket. 2. With wheel centered in swingarm, lower bike to align swingarm and wheel hub. 3. Apply ANIT-SEIZE LUBRICANT to hole in right side of swingarm where axle slides through.  4. See Figure 2-25. Coat the axle with Anti-Seize Lubricant. 5. Slide Axle through right Side of swing arm and wheel hub and thread partially into swingarm on left side. 6. Install idler pulley. See DRIVE BELT INSTALLATION IN SECTION 6.6 DRIVE BELT SYSTEM. 7. See Figure 2-26 (not shown here) Tighten rear axle (1) to 23-27 ft-lbs (31.2-36.6 NM), back off two full turns and then retighten to 48-52 ft-lbs (65.1-70.5Nm). 8. Tighten pinch fastener (2) on right side of swingarm to 40-45 ft-lbs (54-61 Nm). 9. See Figure 2-27. (not shown here) INstall caliper carrier and tighten fastener to 24-26 ft-lbs (23-35 Nm). 10. Pick up one of these manuals. They really are helpful. | ||

Jack82 |

Thanks Bearly..... 10.Yeah I know...it's on the way...  .. .. I gotta stop buying bikes...it's costing me a fortune in manuals.. | ||

Bearly |

That's funny Jack82. I wish I had that problem! I wonder, if we seem to be all assuming that improper torque procedures and values are the culprit here. I wonder if anyone knows of bearings that have fail seemingly early with know proper installation? | ||

Paochow |

So who's the adventurous one who wants to try out some better sealed bearings and report back? | ||

Lorazepam |

When my bearings are replaced, maybe the next owner will volunteer. | ||

Bueluly |

Not sure if this thread is still active however NSK staff has been contacted and the motorcycle application for the NTN 6006 and 6005LU's deep groove ball bearing is being investigated to determine if it is even the right type of bearing. Heavy axial loading is all captured on the inner RACES!!! |